-

Welcome to our new sponsor Lecatona, a brand dedicated to enhancing performance for VAG group sports cars, including SEAT, Audi, Volkswagen and Škoda. Specializing in High Pressure Fuel Pump (HPFP) upgrades.

vario tdi se sort of restoration

- Thread starter Pimped up vario

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Code:

[quote="m0rk, post: 4289407"]That's a shame - looks well with the tints, SEAT rims & white paint[/QUOTE]Thanks. It'll just polish out

poorly running engine

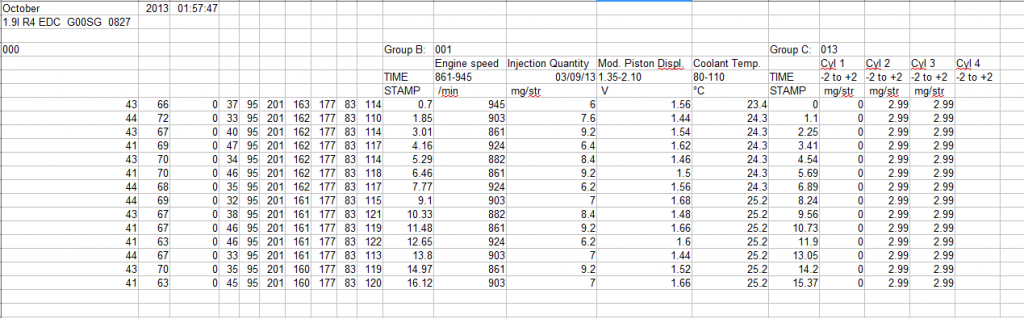

Performed a log with registered vcds-lite with gendan cable. The engine is run from cold.

Here is the log of groups 000, 001 and 013. Trying to observe injection quantity to assess compression and associated cylinder leaks.

What I see from the log is possible compression loss across cylinders 2-4 from the high injection quantities. Don't know why 4 isn't reporting anything. Could someone shed some more light on the log as I'm still learning myself. Going to have a physical look at potential carnage in the morning. All inputs greatly received.

Performed a log with registered vcds-lite with gendan cable. The engine is run from cold.

Here is the log of groups 000, 001 and 013. Trying to observe injection quantity to assess compression and associated cylinder leaks.

What I see from the log is possible compression loss across cylinders 2-4 from the high injection quantities. Don't know why 4 isn't reporting anything. Could someone shed some more light on the log as I'm still learning myself. Going to have a physical look at potential carnage in the morning. All inputs greatly received.

I think your right mate. Lumpy as heck. There is a loud banging noise too which I'm trying to phase out of my mind and haven't told Shelley about but I'll have to face the music eventually.

Last edited:

turbo removed

Done a bit of hoking today.

In the lovely weather.

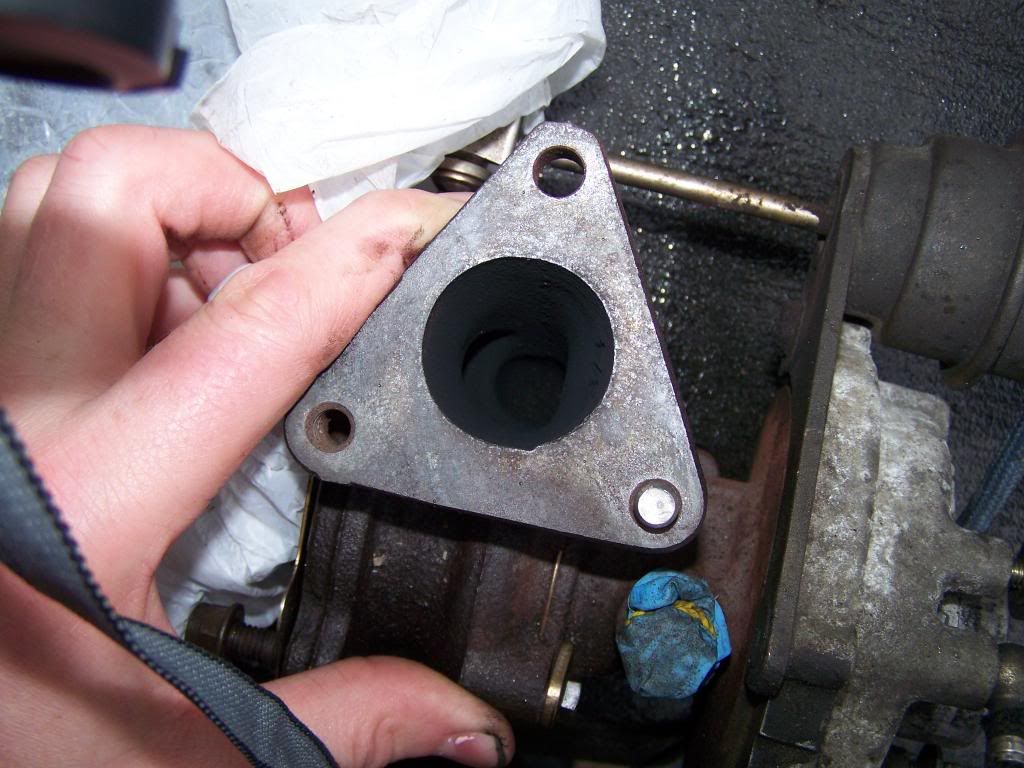

I got the manifolds and blower off the car.

Turbo has a lot of play in it and wheels could very well be hitting the housings, it needs stripped but isn't mangled the way I thought it would be. Will it be obvious or is there a specific pattern I should be looking for? Here's some shots.

And broke a upper securing bolt.

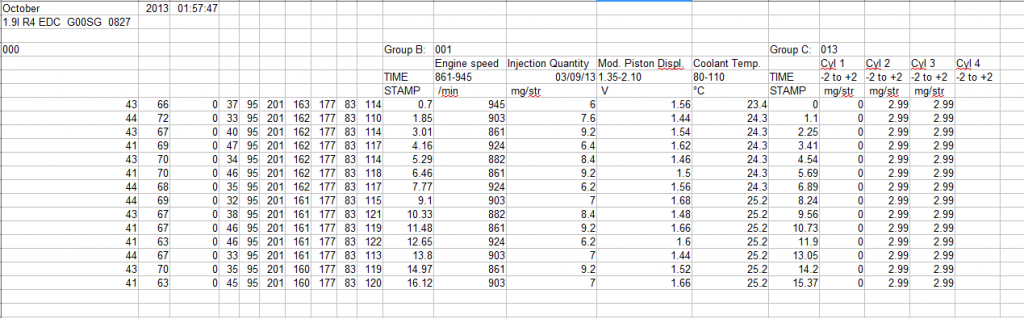

I inspected the exhaust manifold internal channels to see if any evidence was present. The following is cylinder ports 1-4 in ascending order. I didn't find any major cracks or such in the manifold, head or turbo casing. Pardon the lunchtime dishes.

I found one fragment of metal in port 3 but it's hard to say if it was deposited from my glove when handling a nut etc or not. The coppery looking deposits are actually were soot has been removed, nothing came off on my glove when I wiped it. 3 and 4 have the most of these markings in line with the high injection quantities and inferred loss of compression. Exhaust gaskets on 3 and 4 looked like they had blow by as well.

Took the cam cover of and didn't notice anything untoward. Here are pictures of the lobes from 1 - 4. 135k mile engine.

Inside of the cover was clear as well.

The bits that look like fragments of metal are droplets of water sitting on the oil.

So that's the crack so far. Do I need to take the head off? As if I need to ask.

Done a bit of hoking today.

In the lovely weather.

I got the manifolds and blower off the car.

Turbo has a lot of play in it and wheels could very well be hitting the housings, it needs stripped but isn't mangled the way I thought it would be. Will it be obvious or is there a specific pattern I should be looking for? Here's some shots.

And broke a upper securing bolt.

I inspected the exhaust manifold internal channels to see if any evidence was present. The following is cylinder ports 1-4 in ascending order. I didn't find any major cracks or such in the manifold, head or turbo casing. Pardon the lunchtime dishes.

I found one fragment of metal in port 3 but it's hard to say if it was deposited from my glove when handling a nut etc or not. The coppery looking deposits are actually were soot has been removed, nothing came off on my glove when I wiped it. 3 and 4 have the most of these markings in line with the high injection quantities and inferred loss of compression. Exhaust gaskets on 3 and 4 looked like they had blow by as well.

Took the cam cover of and didn't notice anything untoward. Here are pictures of the lobes from 1 - 4. 135k mile engine.

Inside of the cover was clear as well.

The bits that look like fragments of metal are droplets of water sitting on the oil.

So that's the crack so far. Do I need to take the head off? As if I need to ask.

Last edited:

Oh yes, you'll need to mark and pop the cold side housing off the turbo too then you'll be able to see if the compressor has been hitting or not. The edges of the wheel should be all clean and sharp with no cross scraping if you see what I mean.

I think I know what you mean. Square edges, no troughs or scrapes where a straight or radius is. To mark the turbo, is that the wheel in relation to the shaft and end nut?

Last edited:

If the compressor wheel has experienced wear then it would be fair to say that the aluminium housing will have experienced wear as well. I wonder what the tolerance of this is.

Dead on, that's good to know. I'll have to see what the crack is when I get it apart. Have to tackle the head today in rotten weather with a cold  not looking forward to it. I'll dry my eyes here and get on with it.

not looking forward to it. I'll dry my eyes here and get on with it.

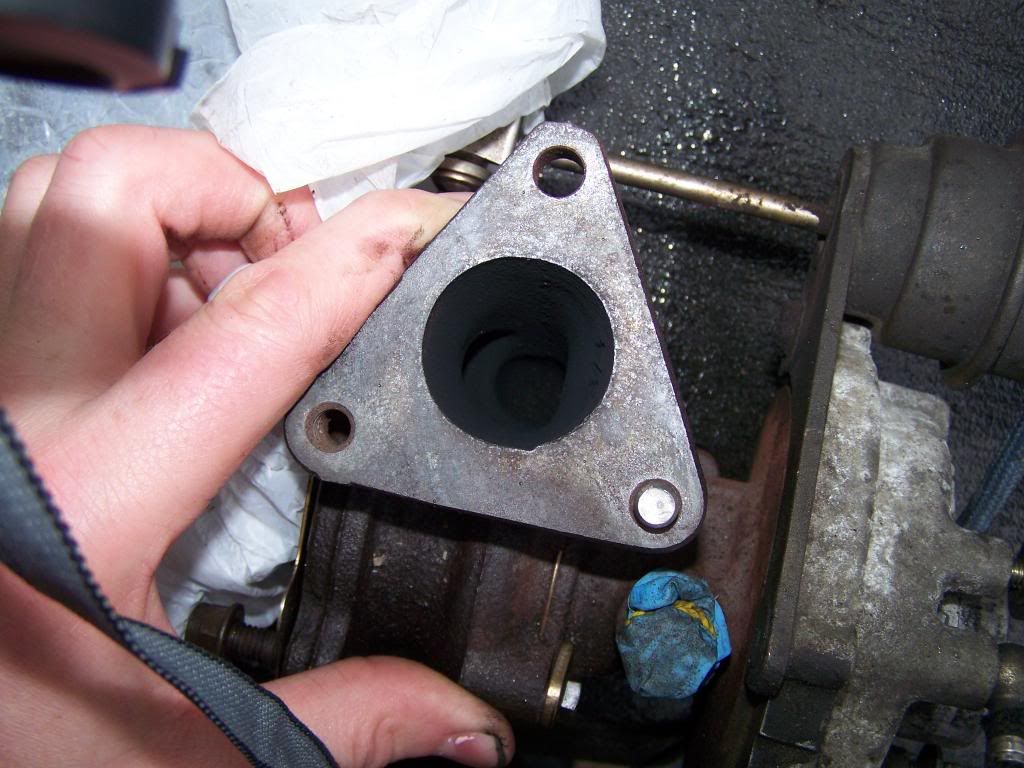

I don't know whether to feel like a donkey/ass or not. I got the timing belt off, pulleys and inner covers, turbo is off and needs refurbed anyway, coolant drained and engine oil drained and lots of connectors, coolant hoses removed. I got to the injector lines and found the number four injector body, which was the cylinder with suspected loss of cylinder compression and not showing any injection quantity on vcds, to be loose in the head. I took it out and cleaned it and reseated it and the restraining bracket tightened back down.

Could the knocking noise (really hard clacking sound) be being caused by uneven injection. A diesel compression test would have been good to eliminate the cylinder head. The threads on the retaining bolt were good and not striped so I don't see it being forced out in any way.

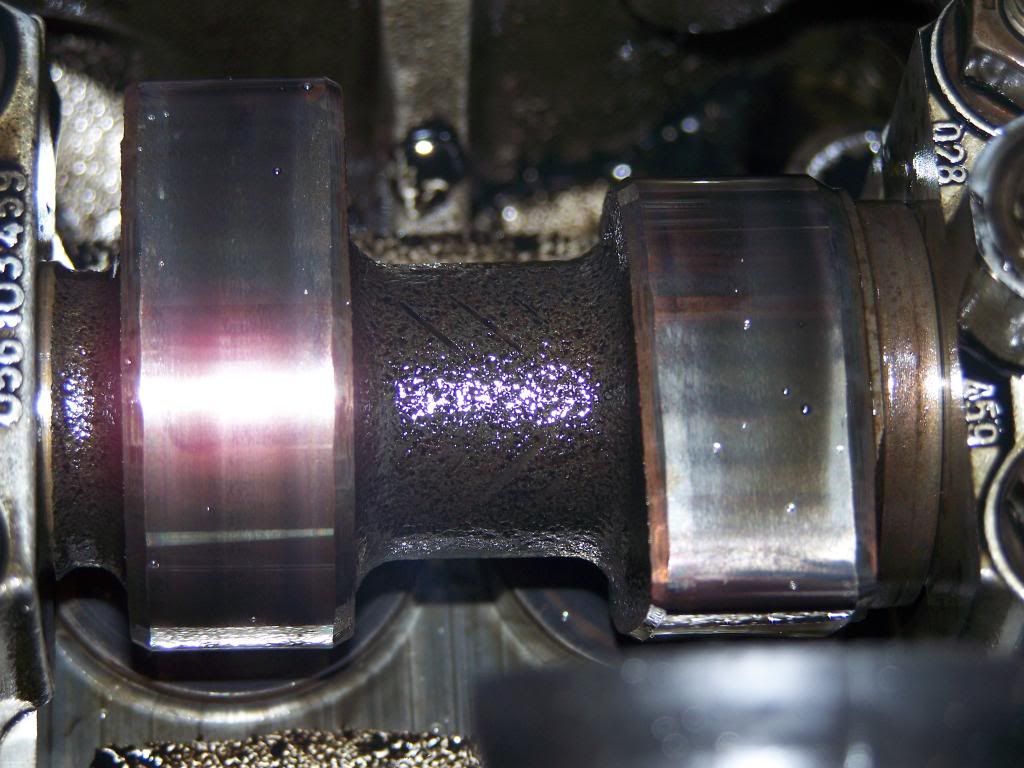

I inspected the underside of the engine with the sump off and all looked good. There didn't feel like there was anything untoward when setting TDC on cylinder no 1.

The followers looked alright but I'll take a closer look tomorrow.

What do you all think.

Could the knocking noise (really hard clacking sound) be being caused by uneven injection. A diesel compression test would have been good to eliminate the cylinder head. The threads on the retaining bolt were good and not striped so I don't see it being forced out in any way.

I inspected the underside of the engine with the sump off and all looked good. There didn't feel like there was anything untoward when setting TDC on cylinder no 1.

The followers looked alright but I'll take a closer look tomorrow.

What do you all think.

Thanks Seatmann. It'd be good if the other three came out as easily and I could put the 0.205um bosch nozzles on in the mean time until I get 0.24um or 0.26um. Just to put her all back together now. I do feel a bit  at doing all that work in taking things off when I didn't have to but on the up side I now know how to do a timing belt change. I know that my engine and oil pickup is healthy and I'll be checking my oil pump for wear before I put my new sump gasket back in. The bolts at the bell housing end are an absolute nightmare to get off, not looking forward to putting them back in again. I found a few bolts missing and a woodruff key missing from the end of the camshaft. So you live you learn. Turbo still needs refurbed but not that sold on refurbing mine when I want to drop in a bigger one. Thanks again.

at doing all that work in taking things off when I didn't have to but on the up side I now know how to do a timing belt change. I know that my engine and oil pickup is healthy and I'll be checking my oil pump for wear before I put my new sump gasket back in. The bolts at the bell housing end are an absolute nightmare to get off, not looking forward to putting them back in again. I found a few bolts missing and a woodruff key missing from the end of the camshaft. So you live you learn. Turbo still needs refurbed but not that sold on refurbing mine when I want to drop in a bigger one. Thanks again.

at doing all that work in taking things off when I didn't have to but on the up side I now know how to do a timing belt change. I know that my engine and oil pickup is healthy and I'll be checking my oil pump for wear before I put my new sump gasket back in. The bolts at the bell housing end are an absolute nightmare to get off, not looking forward to putting them back in again. I found a few bolts missing and a woodruff key missing from the end of the camshaft. So you live you learn. Turbo still needs refurbed but not that sold on refurbing mine when I want to drop in a bigger one. Thanks again.

at doing all that work in taking things off when I didn't have to but on the up side I now know how to do a timing belt change. I know that my engine and oil pickup is healthy and I'll be checking my oil pump for wear before I put my new sump gasket back in. The bolts at the bell housing end are an absolute nightmare to get off, not looking forward to putting them back in again. I found a few bolts missing and a woodruff key missing from the end of the camshaft. So you live you learn. Turbo still needs refurbed but not that sold on refurbing mine when I want to drop in a bigger one. Thanks again.You can get those bolts with a 5mm ball ended allen key, pretty easy then. There's no key for the cam, you lock the other end and leave the pulley to move when tensioning the belt. The end of the shaft is a bit tapered and the pulley jams on once tightened.

Pulling it apart and putting it back together is a good way to learn too

Pulling it apart and putting it back together is a good way to learn too

Dead on, thanks for the tips. Cracked the ribbed crankshaft end pulley too. Ha ha. It'll be allright there's still three good holes.

Turbo apart

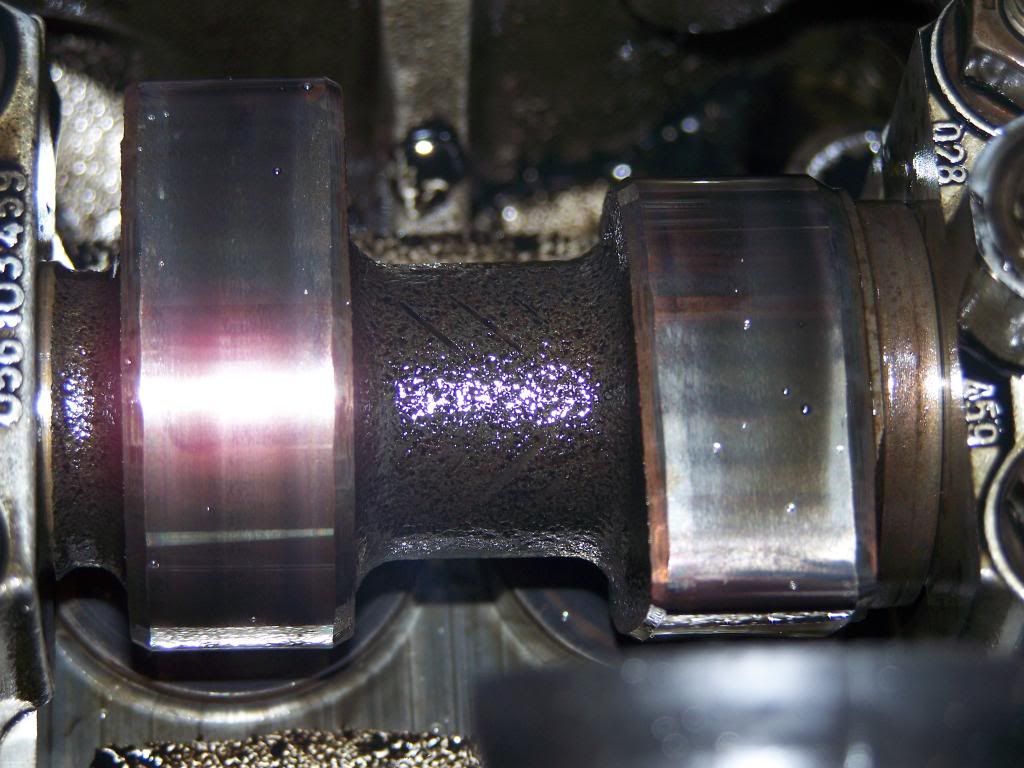

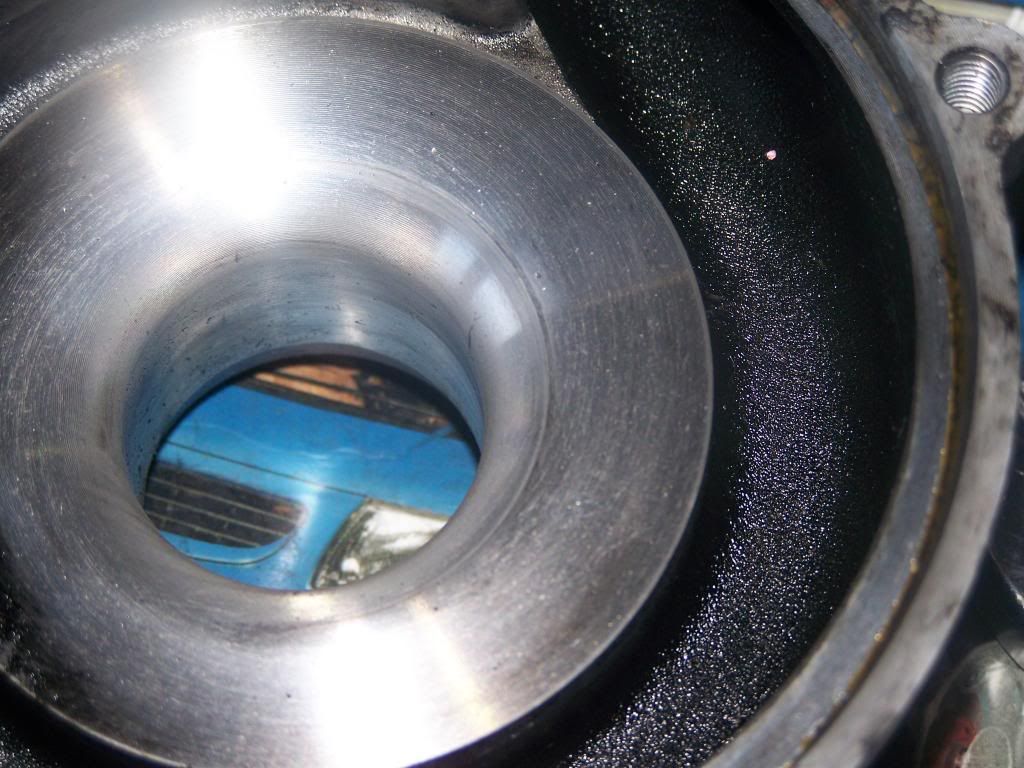

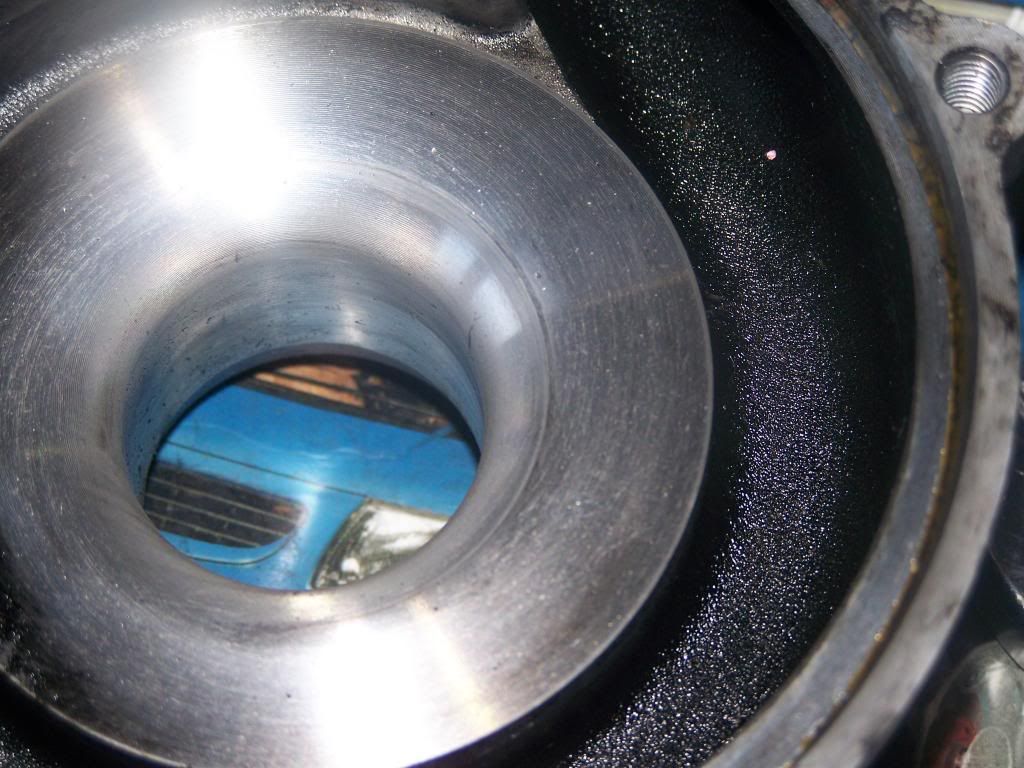

Yehaaa. Sort of. I got the turbo apart but with mixed results. It doesn't look too bad but not too good either. I'll let you be the judge.

Same fin area, two different photographs.

The turbine side has very lightly shined a small part of the inside surface of the hotside housing and the turbine fins look untouched.

The coldside is a different story. The inside of the housing is showing signs of wear but it is minimal as in I can still see the v pattern that is left by the machining process. The depth of the v is very small to start with and the worn part is still quite visible. The compressor wheel itself is a different matter. The v pattern from the housing has transferred to the wheel edges and as you can see one section looks decidedly dodgy. There is also a lip/burr edge present on some of the fins outer edge where it has been contacting the housing. That's that then.

Yehaaa. Sort of. I got the turbo apart but with mixed results. It doesn't look too bad but not too good either. I'll let you be the judge.

Same fin area, two different photographs.

The turbine side has very lightly shined a small part of the inside surface of the hotside housing and the turbine fins look untouched.

The coldside is a different story. The inside of the housing is showing signs of wear but it is minimal as in I can still see the v pattern that is left by the machining process. The depth of the v is very small to start with and the worn part is still quite visible. The compressor wheel itself is a different matter. The v pattern from the housing has transferred to the wheel edges and as you can see one section looks decidedly dodgy. There is also a lip/burr edge present on some of the fins outer edge where it has been contacting the housing. That's that then.

Last edited:

I got a turbo rebuild kit. I kept the balance of the old one and didn't get a new compressor wheel as I what to get a gt1749a anyway. The new bearings are only a damage limitation thing as the turbo was making boost before it was removed, just lots of movement.

Checked the oil pump for wear, 0.5mm axial clearance and backlash of 0.15mm. Limit is 0.15mm and 0.2mm respectively. Put new sump gasket in place and removing the old seal was a lengthy nightmare. The sump does have a dent in it but it's nowhere near the internals and it isn't reducing the overall capacity of oil held in the sump by much and isn't interfering with the pickup or baffle function.

Removed the oil cooler and the mounting bracket from the engine block, cleaned them and put new gaskets in place. It was a nightmare and very limited space making for sore hands and arms, poor baby , and hands were dirty, parts were clean, so no photos sorry.

, and hands were dirty, parts were clean, so no photos sorry.

I think the source of the oil leak at the front of the block is from were the crankcase ventilation hose meets the engine block as it is falling apart but at least the oil cooler can be ruled out.

Checked the oil pump for wear, 0.5mm axial clearance and backlash of 0.15mm. Limit is 0.15mm and 0.2mm respectively. Put new sump gasket in place and removing the old seal was a lengthy nightmare. The sump does have a dent in it but it's nowhere near the internals and it isn't reducing the overall capacity of oil held in the sump by much and isn't interfering with the pickup or baffle function.

Removed the oil cooler and the mounting bracket from the engine block, cleaned them and put new gaskets in place. It was a nightmare and very limited space making for sore hands and arms, poor baby

I think the source of the oil leak at the front of the block is from were the crankcase ventilation hose meets the engine block as it is falling apart but at least the oil cooler can be ruled out.

Similar threads

- Replies

- 1

- Views

- 367