No real experience building manifolds ......I can't see it being a major headache as such..

Guest, 🎅🎄Looking for a stocking filler idea? Why not treat yourself or a loved one to our high quality CUPRA or SEAT valve caps. Order now from the merchandise store

No real experience building manifolds ......I can't see it being a major headache as such..

not mine no.

I wont be selling badgerwagen any time soon

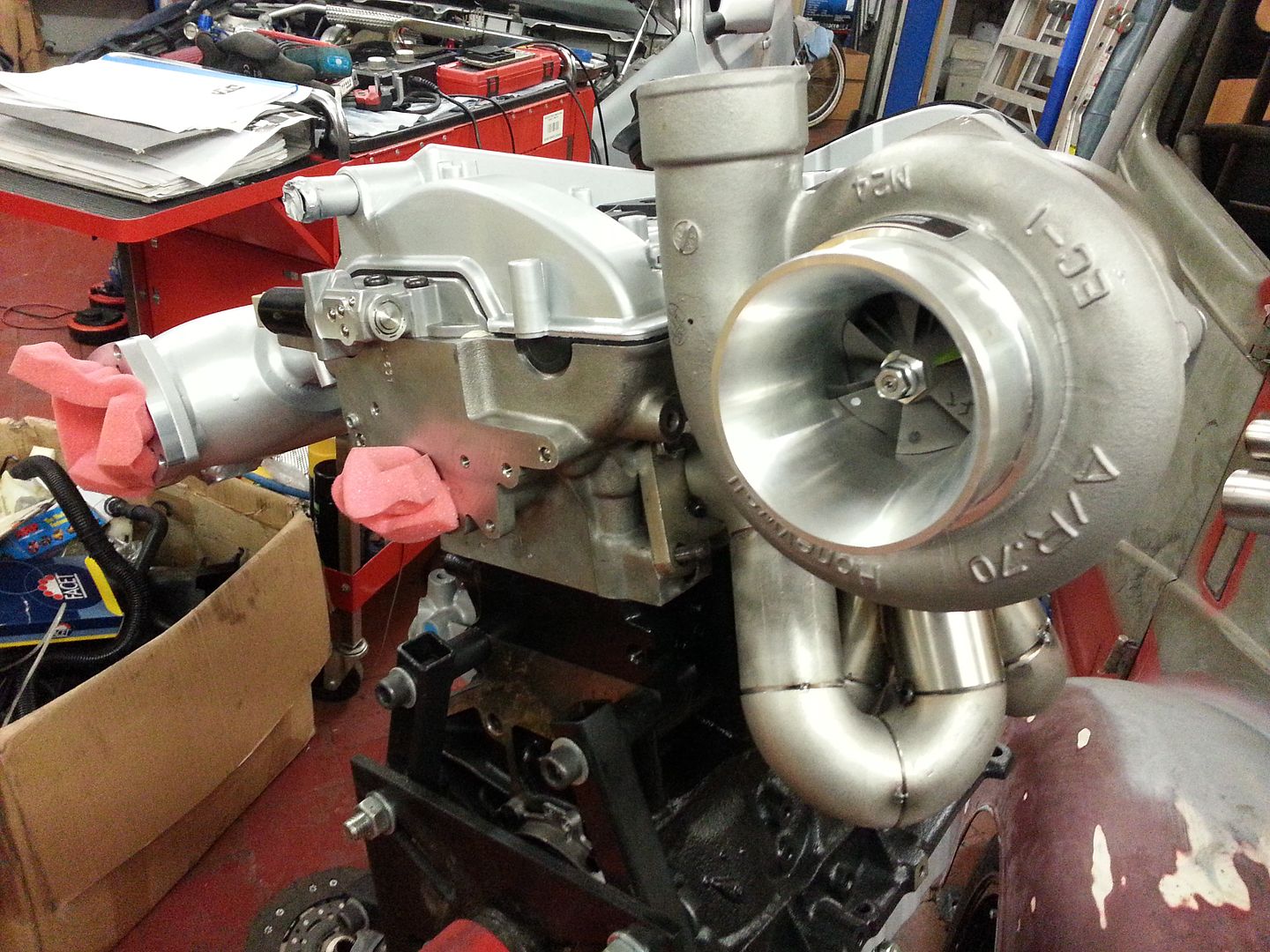

Ahh, i always thought it was best for equal lengths, may make it a fair bit easier for me. Where do you plan to mount your turbo? Still tucked down behind or is it too big for that now? Are you still keeping the same tial gate?

Certainly sounds like i need something with 4wd haha, that much power but still usable in all weathers. Even in the wet my ibiza spins in 5th if too happy. Thats a total different thing to yours though haha.

Being honest, watching yours come along aswell as a lot of others on here, its really making me want to take mine to bill next year. It was previously done at r ****. Wherever i go it will be a travel and a week or so in a hotel but bills work, mapping and customer service never seems to fail.

Does bill do your mapping or do you get let loose?

good luck i can wait to see how it turns out

good luck i can wait to see how it turns out

Thanks all... went better than I expected tbh... surprised myself...

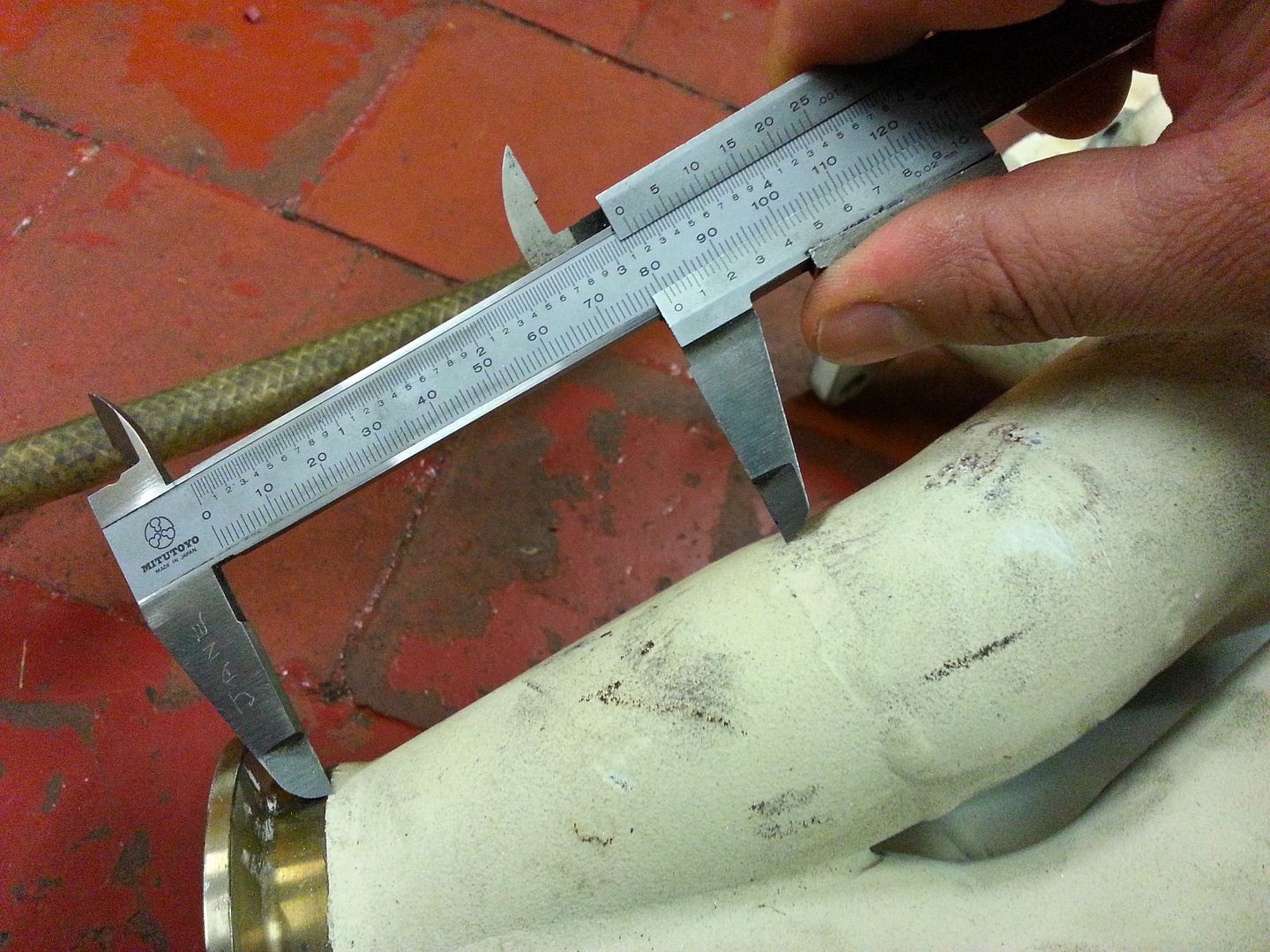

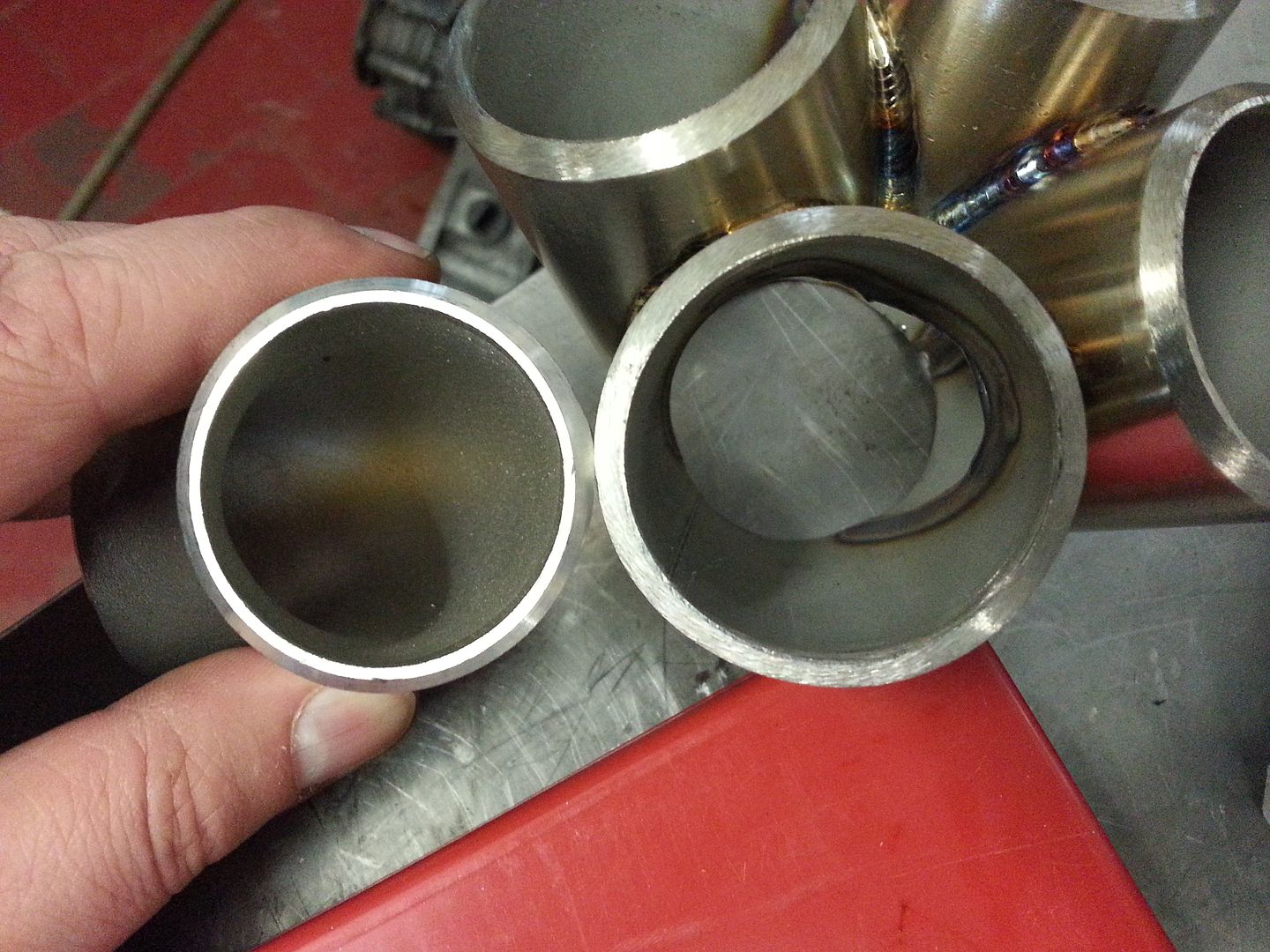

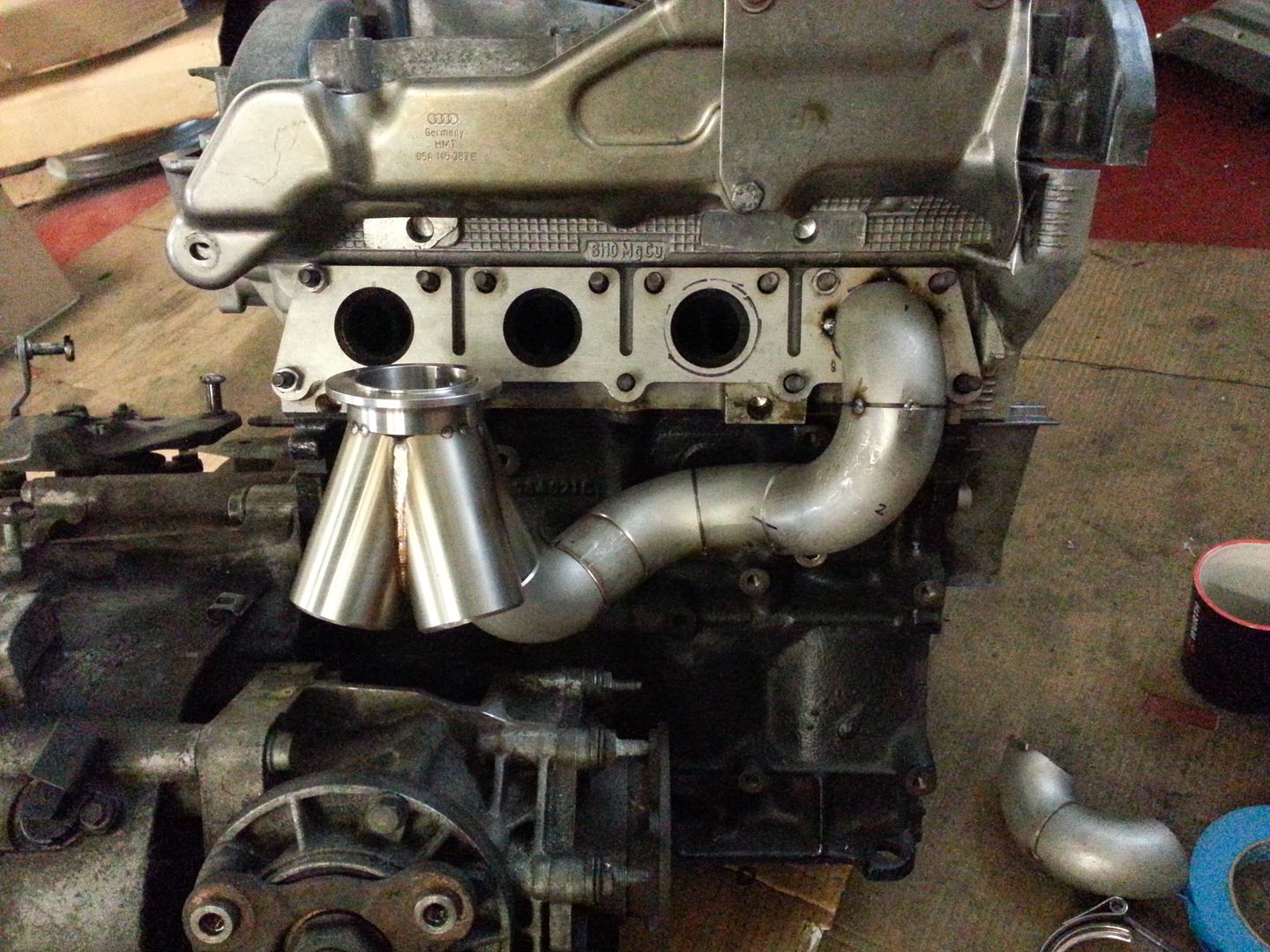

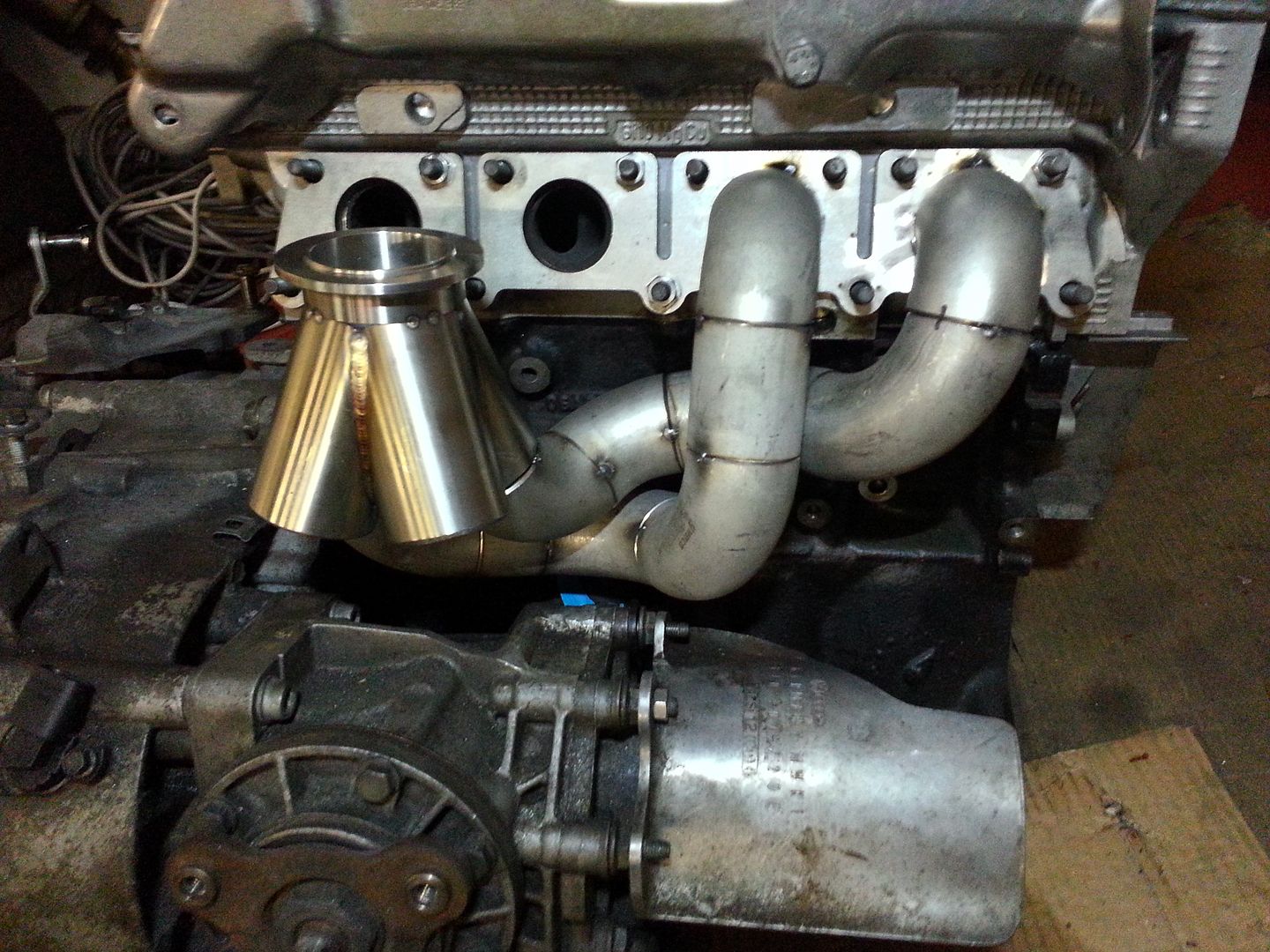

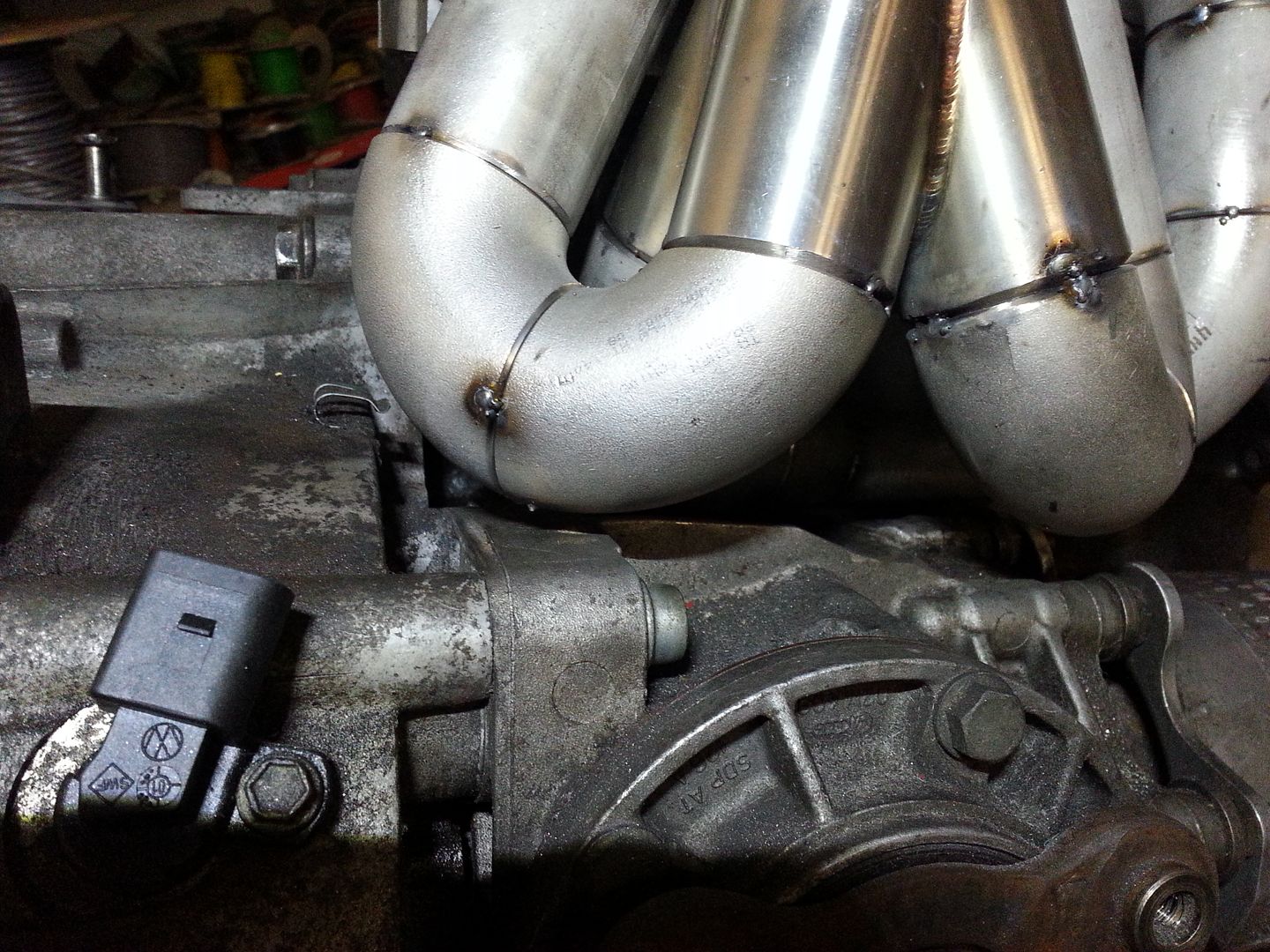

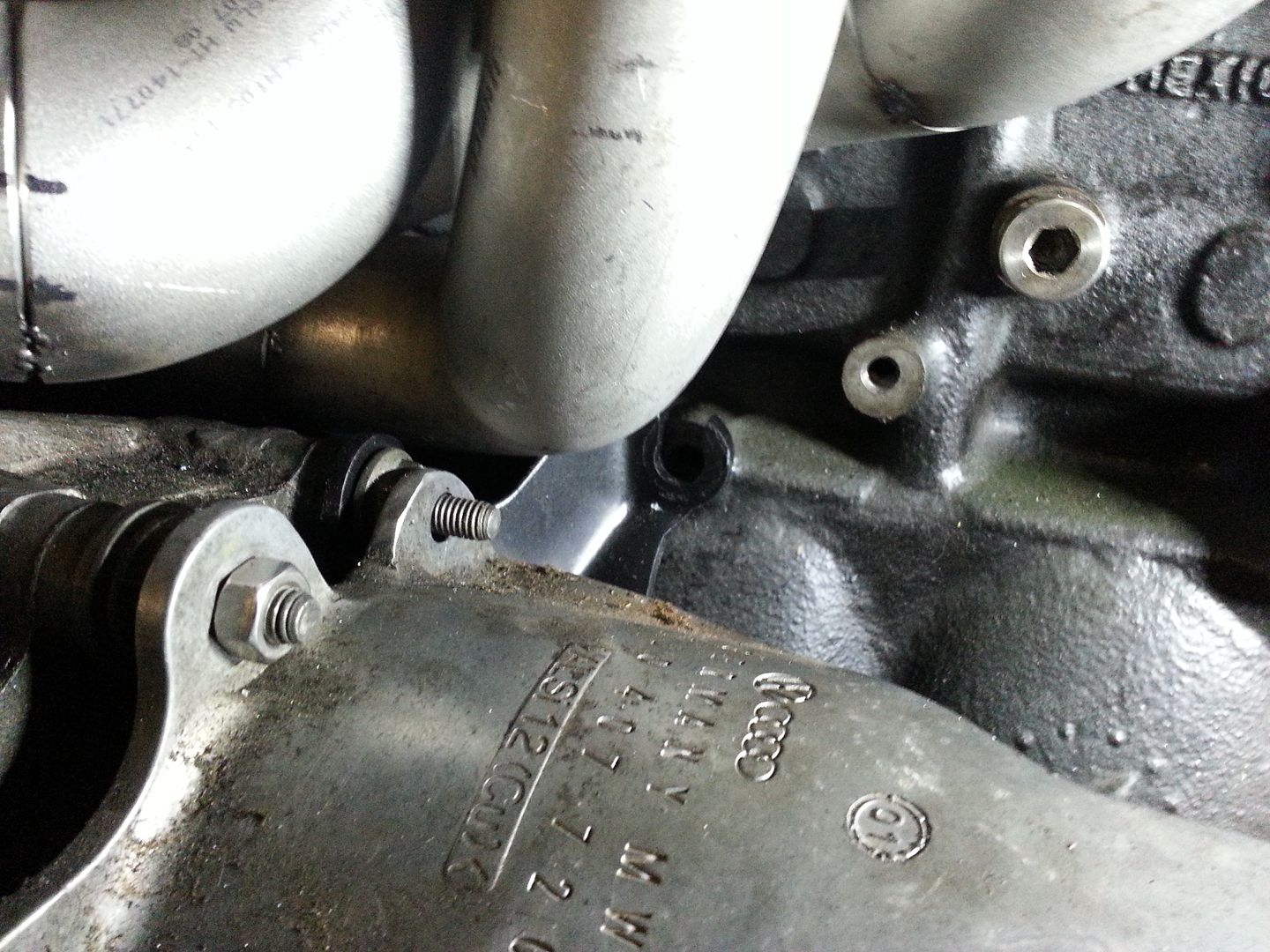

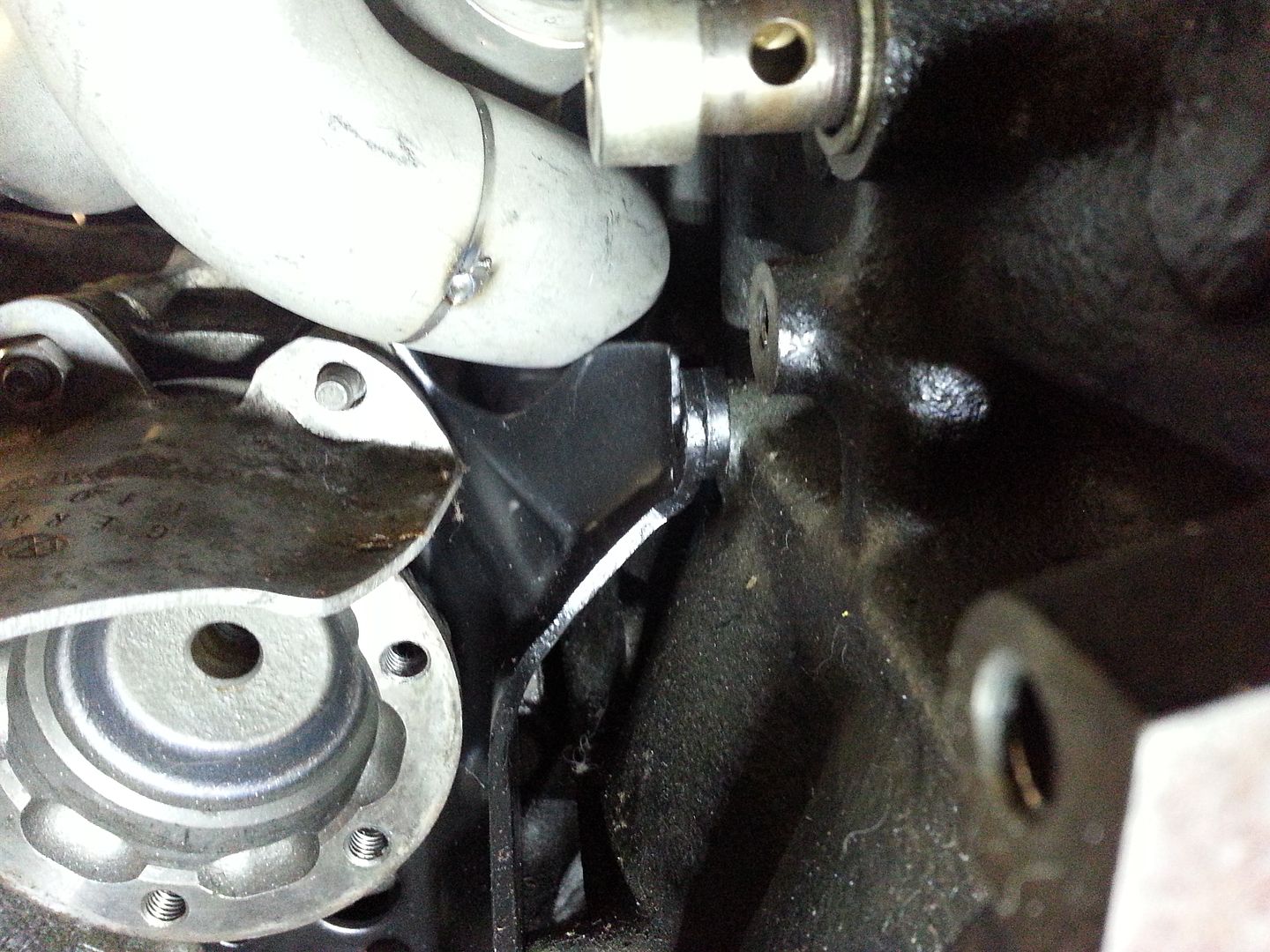

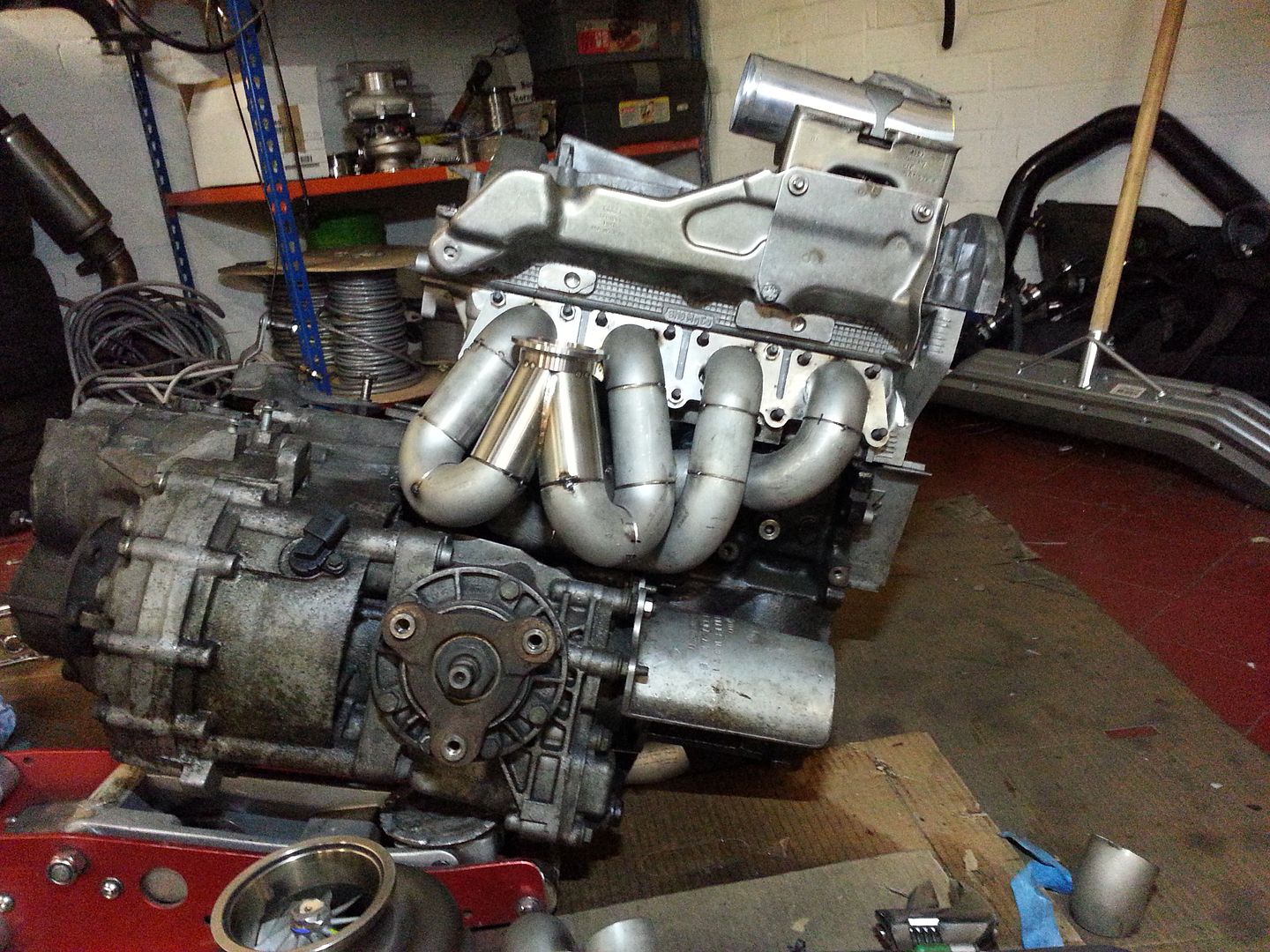

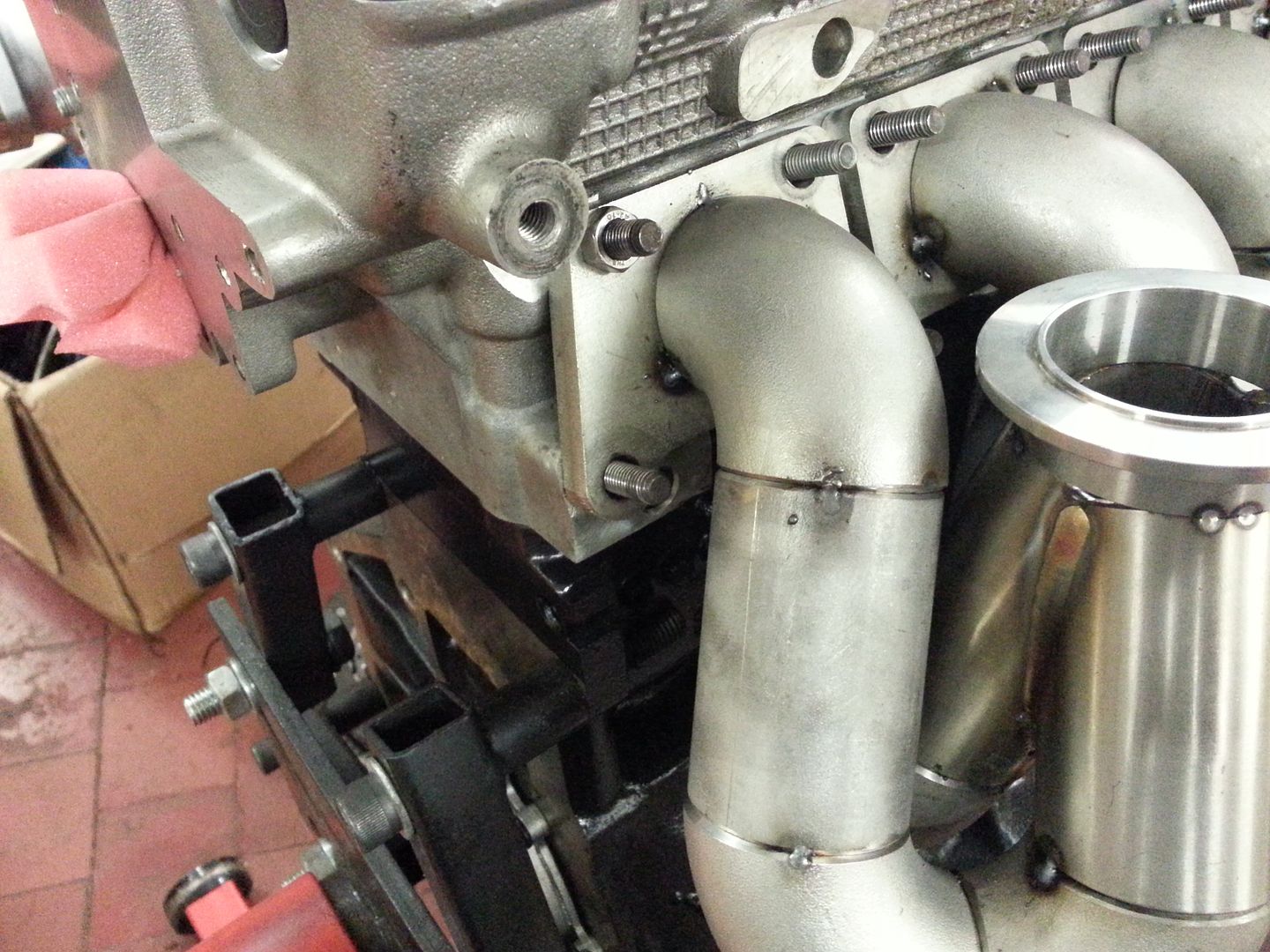

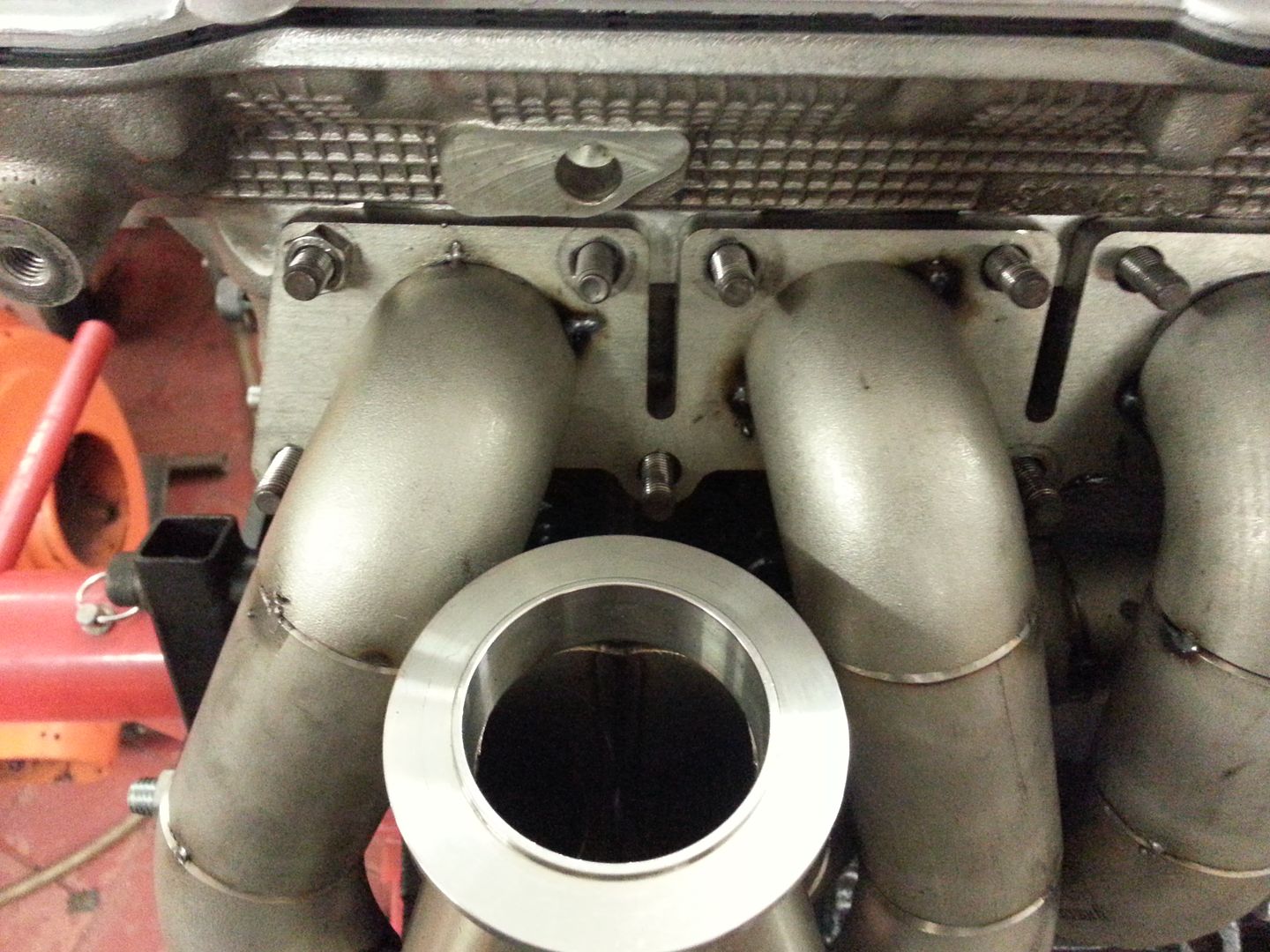

I used cast bends of which I only needed to tweak the angle of two bends to get it aligned correctly... using a combo of tight and not so tight 90 deg bends plus 45 deg bends seemed to allow enough flexibilty to use them out the box... had to tighten the bend coming from the collector to cyl 4 so it would clear the transfer box..

Used a chop saw for the straight pieces, cleaned up the ends with a grinding wheel and bevelled the ends (for butt welding) on a linisher...

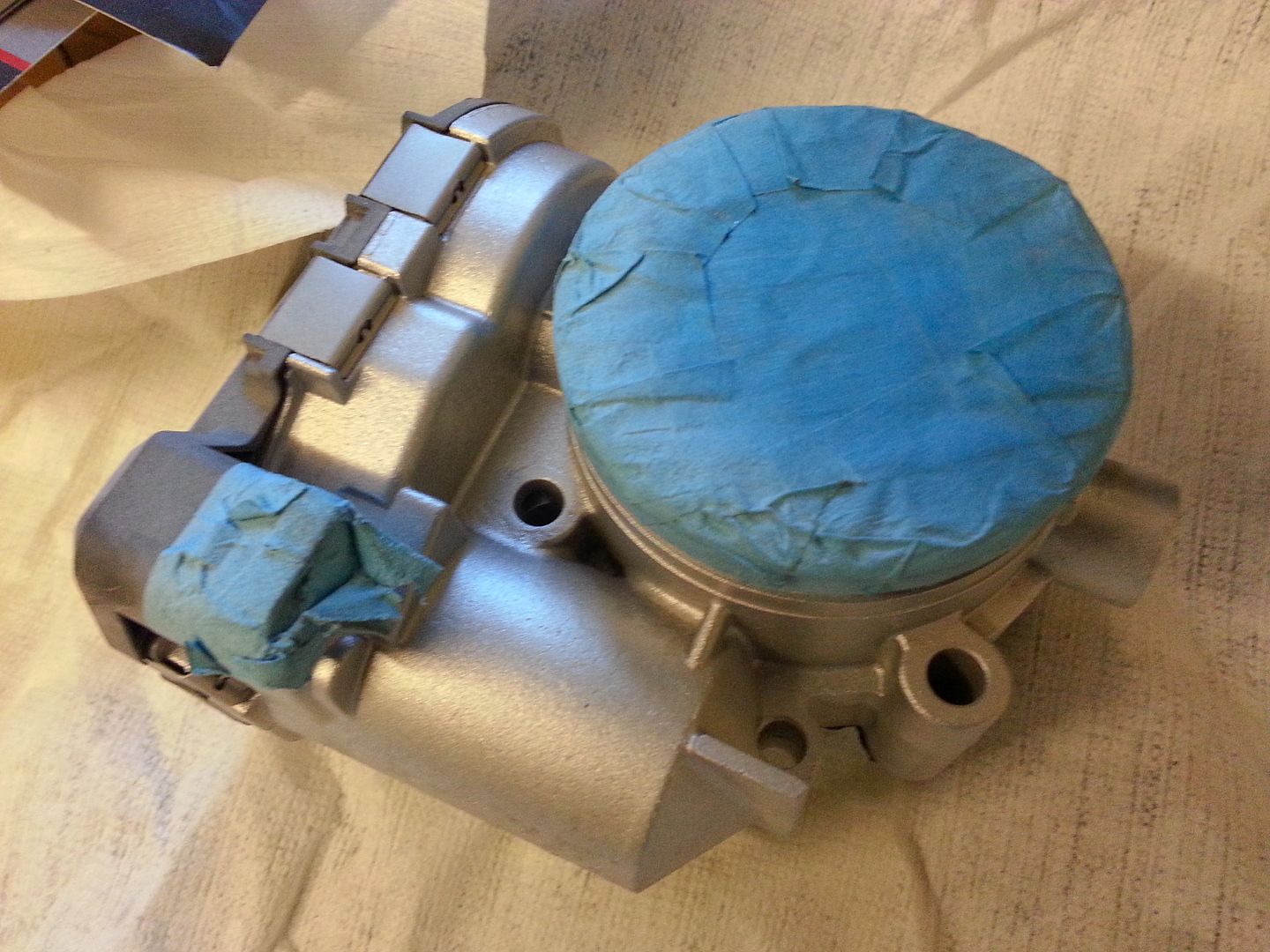

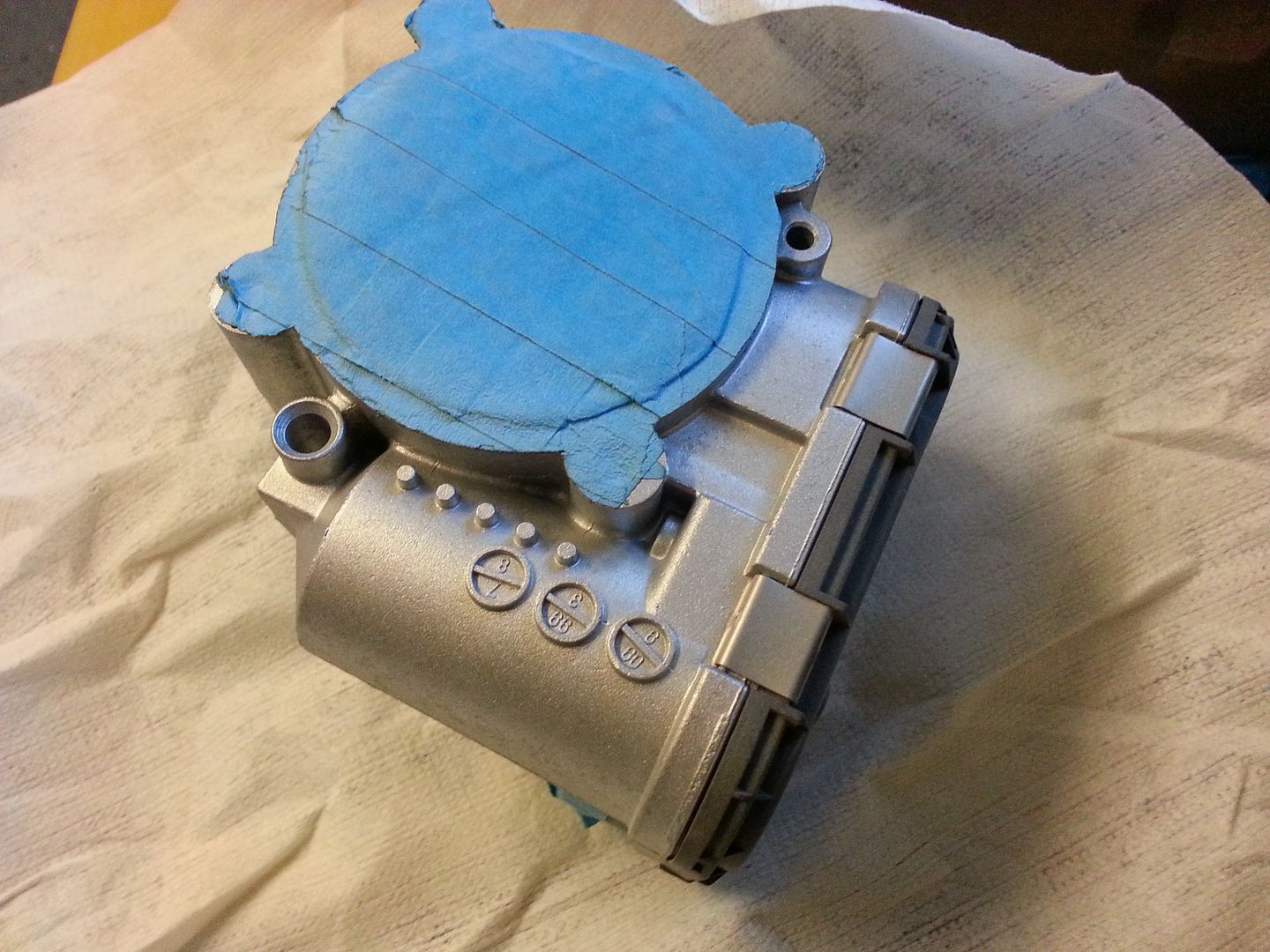

Tacked using a MIG (first time I have ever used a welder) and either Bill or another guy we know will be doing the final TIG once I have sorted the wastegate out

<tuffty/>

Maybe i have to invest in some of the tighter bends, i only have the long ones and a length of straight pipe.

Looks very tight there which worries me, as im trying to do the same but in a mk3 ibiza not an s3 haha.

Im tackling the whole job myself aswell, bought a tig welder for doing all my own work plus for other people too, so will be teaching myself how to weld strongly and neatly with tig, back purging and welding the mani myself.

I do look forward to seeing yours fully welded and on the car. Are you getting it ceramic coated or wrapped?