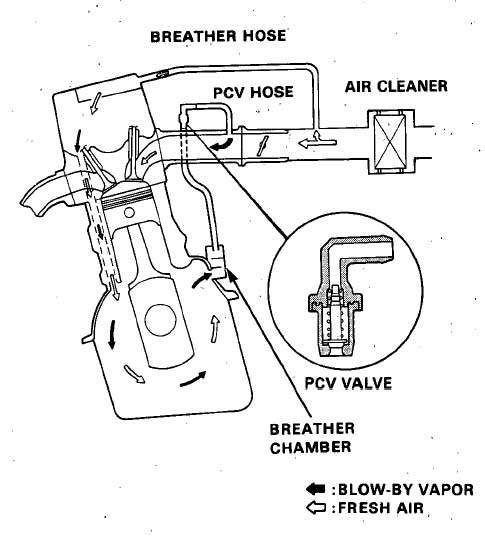

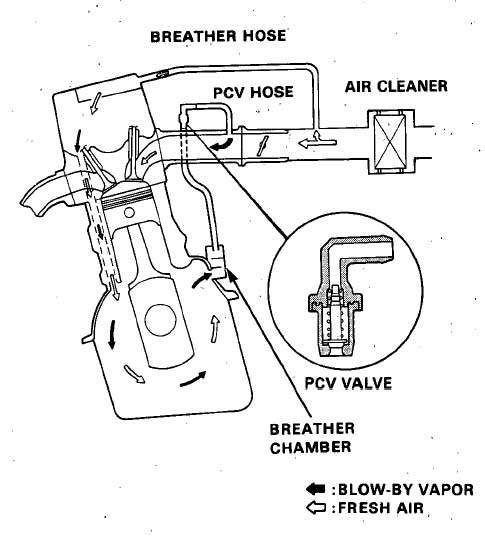

I don't know how crankcase ventilation is done on this engine. It should be done like this schematics show

but I can't find any crankcase connections.

I make a photo of the engine bay where I think one of the connection of PCV is.

The rubber pipe maked with red bigger square should be the higher pressure point and air should be sucked here, but instead if you disconnect this it blows off. There is also some other samller rubber pipe (marked with smaller square) that comes from intake manifold to here as seen on the pic. The third rubber pipe (marked with red circle goes to charcoal filter and is used for something else).

but I can't find any crankcase connections.

I make a photo of the engine bay where I think one of the connection of PCV is.

The rubber pipe maked with red bigger square should be the higher pressure point and air should be sucked here, but instead if you disconnect this it blows off. There is also some other samller rubber pipe (marked with smaller square) that comes from intake manifold to here as seen on the pic. The third rubber pipe (marked with red circle goes to charcoal filter and is used for something else).