I've found out the size of bolts I need to get by emailing ATP.

Do I just buy standard items or should I try to get some thing special (in terms of metallic composition) ?

Do I just buy standard items or should I try to get some thing special (in terms of metallic composition) ?

(wire melts?) or use other mechanical locking washers.

(wire melts?) or use other mechanical locking washers.

I've just read your other thread. Nice one.

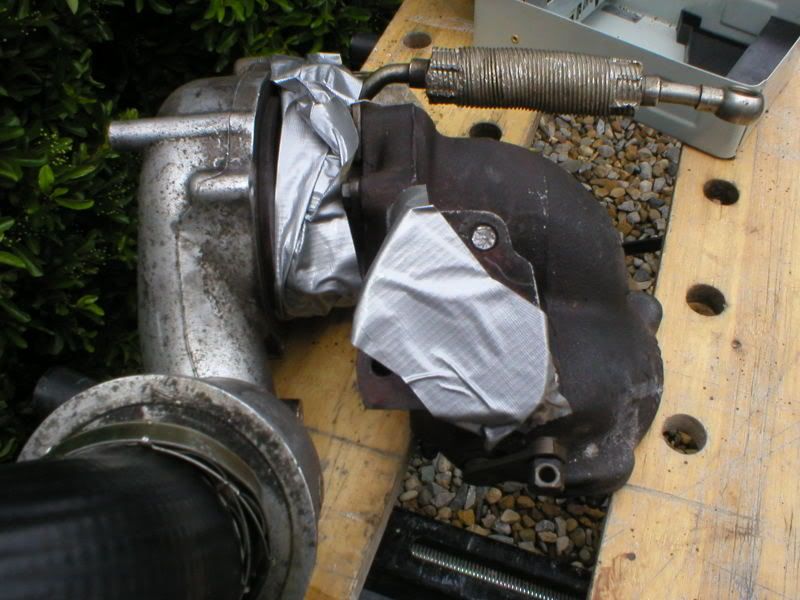

I've just read your other thread. Nice one. Turbo and manifold removal... not for the faint hearted.

Turbo and manifold removal... not for the faint hearted.