Stop Screw Adjustment 1749VC Hybrid

- Thread starter S10EAT

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dan,

I've got all the parts I need to remove the stop screw, I'm now struggling with finding a post lift to borrow for an hour or so! Jacks aren't going to give me enough room to get a cordless drill under my car!

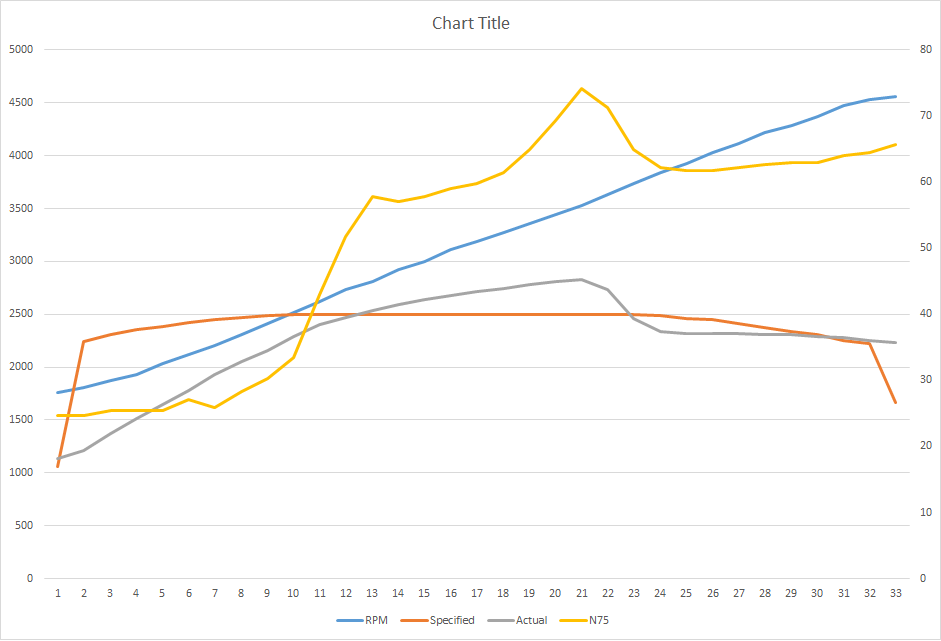

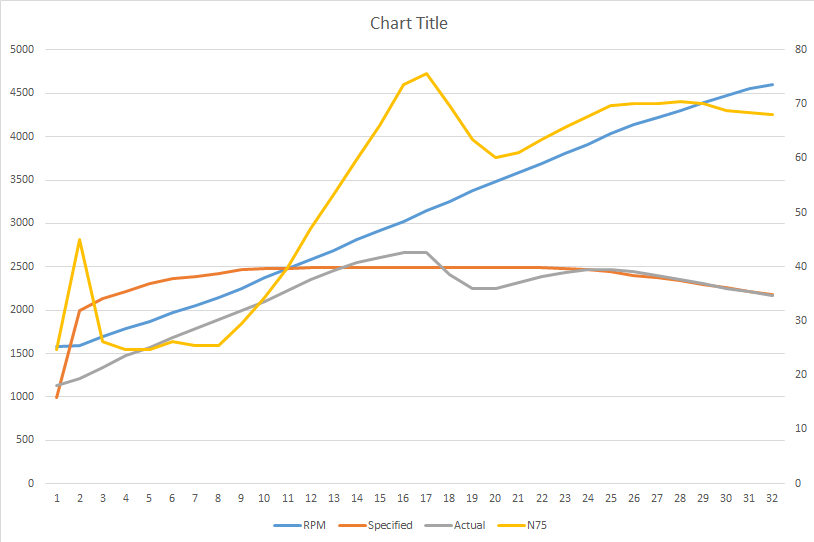

Thanks for your help so far, just an update I put the standard map on a few days ago and it's still over boosting around the same range on the above graph, does this mean that the actuator is too long and not as sensitive enough to control boost? I've checked for boost leaks and as far as I know have none.

Vacuum pump/gauge arrived yesterday tested and I'm pulling 27.5 hg after the white/black check valve at idle which is in spec I believe?

Cheers,

S10EAT

I've got all the parts I need to remove the stop screw, I'm now struggling with finding a post lift to borrow for an hour or so! Jacks aren't going to give me enough room to get a cordless drill under my car!

Thanks for your help so far, just an update I put the standard map on a few days ago and it's still over boosting around the same range on the above graph, does this mean that the actuator is too long and not as sensitive enough to control boost? I've checked for boost leaks and as far as I know have none.

Vacuum pump/gauge arrived yesterday tested and I'm pulling 27.5 hg after the white/black check valve at idle which is in spec I believe?

Cheers,

S10EAT

Last edited:

Have you got the log? It will still underboost then overboost massively as the N75 map is miles out, i would have expected less specified and less actual though.

Looking at last graph the actuator could be a little long, but get the stopscrew sorted first.

Nothing in autodata for vacuum pressure but 27.5hg sounds plenty to me, more than enough for N75.

Looking at last graph the actuator could be a little long, but get the stopscrew sorted first.

Nothing in autodata for vacuum pressure but 27.5hg sounds plenty to me, more than enough for N75.

With Dan on this one, the stopscrew needs sorting first and then the actuator can be sorted out from the resulting logs.

Well last night I decided to have a go at replacing my tandem pump, although some of the access/space was fiddly I completed the job without too much bother.

Old Tandem Pump - LUK black cover version

Bosch Tandem Pump from newer 1.9 model

Oil/Fuel leak over gearbox

Going to run a boost log at lunch to see if the replacement tandem pump has improved things in any way.

As for the actuator and stop screw I will hopefully be sorting these at the weekend.

Thanks for your assistance so far.

S10EAT

Old Tandem Pump - LUK black cover version

Bosch Tandem Pump from newer 1.9 model

Oil/Fuel leak over gearbox

Going to run a boost log at lunch to see if the replacement tandem pump has improved things in any way.

As for the actuator and stop screw I will hopefully be sorting these at the weekend.

Thanks for your assistance so far.

S10EAT

Were you recommended to get the Tandem Pump replaced?

Let use know how you get on.

Badger,

Wasn't recommended by anyone but it was leaking fuel/oil out the back, I wanted a bit of piece of mind as the original tandem pump has probably done the same as the car mileage which is 192,000! So I thought as I've got it out might as well replace it with a newer revision bosch type.

I had some success today, managed to free up the actuator enough and found that there was still some adjustment left in it, made a couple of turns to lengthen and overboost has come down.

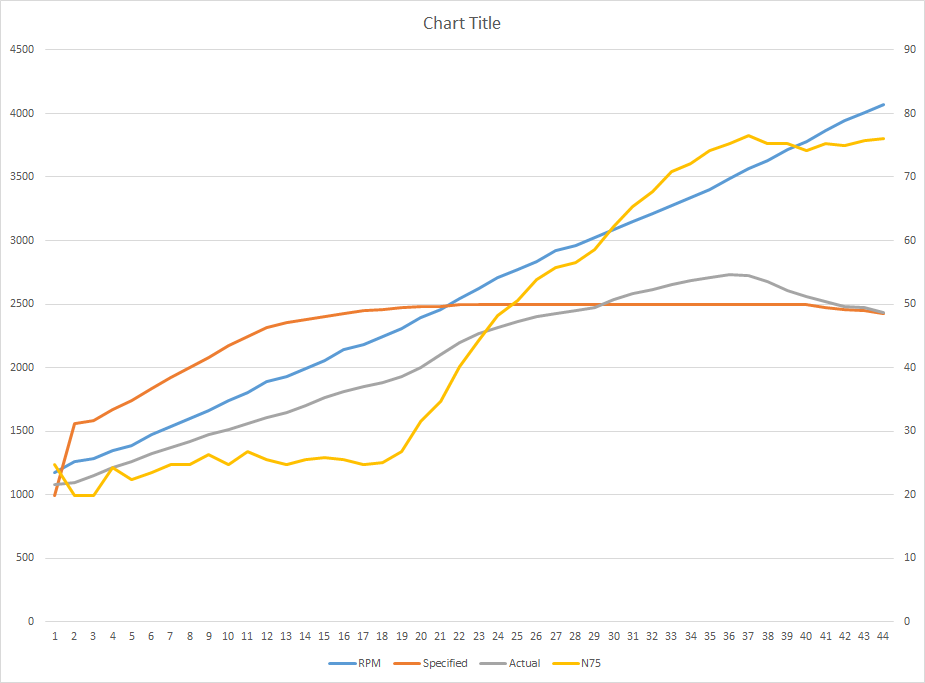

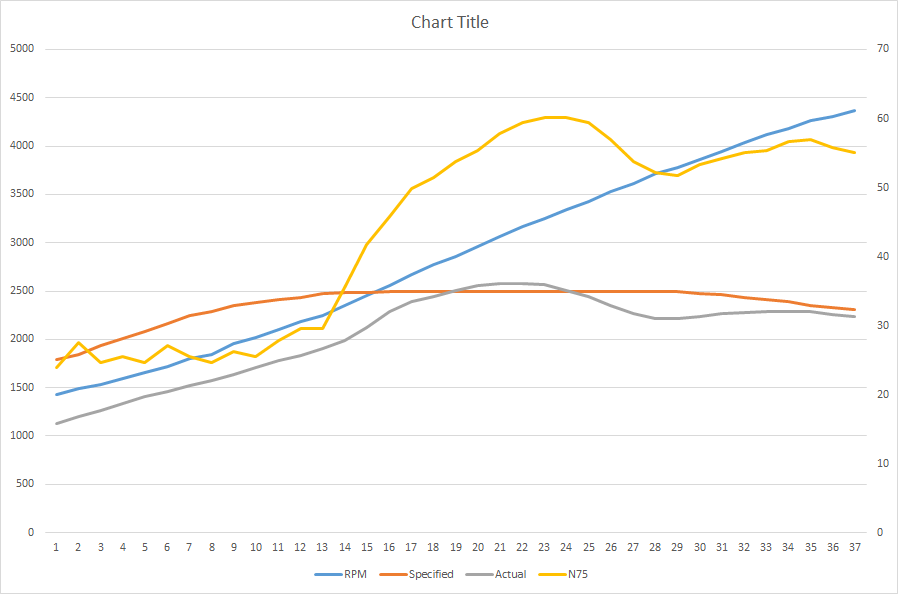

Here's a boost log I've just made, can anyone explain why I've got so much underboost in the upper rev range? Also the car struggles to reach top speed, why would the car struggle at top end? This was logged with the standard PD150 map no adjustments.

Thanks,

S10EAT

Looks like the N75 opens the vanes too much to correct the over boost, that's the reason why you feel a dip in power. You can see that boost slowly starts to build just before you hit the redline.

There is also a chance you over lengthened the rod. Now comes adjustment time!

You should still be boosting earlier than that. Stop screw adjustment needed next I reckon.

There is also a chance you over lengthened the rod. Now comes adjustment time!

You should still be boosting earlier than that. Stop screw adjustment needed next I reckon.

Last edited:

Looking at previous logs it didn't need lengthening. its a combination of an unsuited map/N75 control and the stop screw.

Looking at current log, specified and actual almost meet at 4000rpm and youre mid 50's on the DC which is far far too low

Looking at current log, specified and actual almost meet at 4000rpm and youre mid 50's on the DC which is far far too low

Dan,

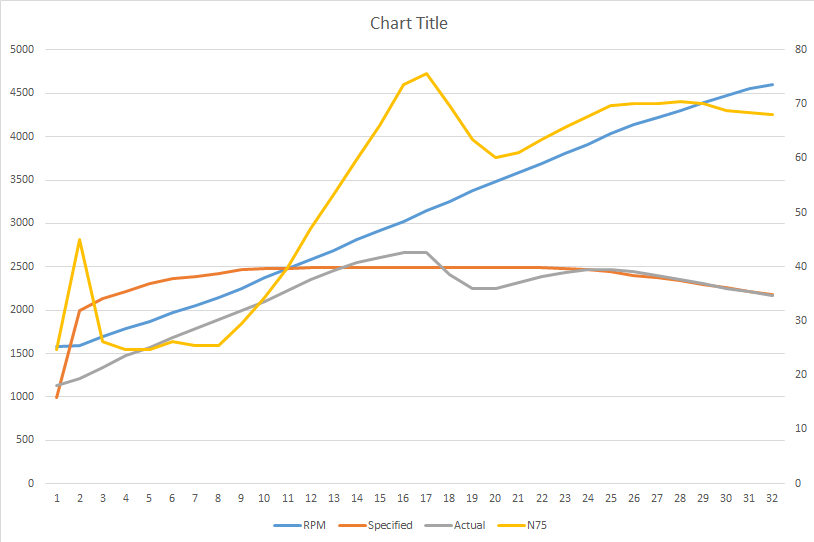

Can you work out why I'm getting this spike at 2700-2800 rpm?

The actuator has been various different lengths and it has always spiked in the same place or would this change to lower down the range once the stop screw was adjusted?

I did originally have the actuator at4000 rpm set to around 70-75% DC which you can see below:

I'm so confused because I've had it short, in between and long, longer and it's all been a bit of an issue, any advice, I realise the stop screw needs doing but surely this wouldn't account for the problems 2700 RPM onwards would it?

Thanks,

Dominic

Can you work out why I'm getting this spike at 2700-2800 rpm?

The actuator has been various different lengths and it has always spiked in the same place or would this change to lower down the range once the stop screw was adjusted?

I did originally have the actuator at4000 rpm set to around 70-75% DC which you can see below:

I'm so confused because I've had it short, in between and long, longer and it's all been a bit of an issue, any advice, I realise the stop screw needs doing but surely this wouldn't account for the problems 2700 RPM onwards would it?

Thanks,

Dominic

Forget about the spike for now, the spike is down to mapping being so far out from what the turbo is actually delivering. ECU is having to react to readings and will always be playing catchup and on the back foot.

Once you sort the stop screw and boost comes in earlier, the spike will occur earlier in the rev range. It may even be worse as the turbo should spool up a lot more urgently.

Get the stop screw sorted so that the turbo will spool when the ECU asks it to, keep the actuator length so that N75 DC is 75%ish for now - headroom for more control when mapped at a later date.

The rest, including the spike, is down to the mapping, which you can get sorted once hardware is right.

Once you sort the stop screw and boost comes in earlier, the spike will occur earlier in the rev range. It may even be worse as the turbo should spool up a lot more urgently.

Get the stop screw sorted so that the turbo will spool when the ECU asks it to, keep the actuator length so that N75 DC is 75%ish for now - headroom for more control when mapped at a later date.

The rest, including the spike, is down to the mapping, which you can get sorted once hardware is right.

Forget about the spike for now, the spike is down to mapping being so far out from what the turbo is actually delivering. ECU is having to react to readings and will always be playing catchup and on the back foot.

Once you sort the stop screw and boost comes in earlier, the spike will occur earlier in the rev range. It may even be worse as the turbo should spool up a lot more urgently.

Get the stop screw sorted so that the turbo will spool when the ECU asks it to, keep the actuator length so that N75 DC is 75%ish for now - headroom for more control when mapped at a later date.

The rest, including the spike, is down to the mapping, which you can get sorted once hardware is right.

Thanks Dan.

Ok am I right in thinking if my basic settings is telling me that I have a 144 mbar difference at the moment that I a) need it closer to 200mbar and b) it needs to be shortened (unscrewed) for this value to go up?

Thanks for your help, much appreciated it's been doing my head in for quite a few months now!

S10EAT

Im not sure you will quite get 200 as you have a hybrid/higher flowing turbo that probably wont be as responsive as the original. Dont go too crazy on the adjustments either as spool wont be perfect without better mapping

Unscrew to allow vanes to close further for better spool, run logs after each adjustment. Ideally you want logs of boost, fuelling and MAF readings

Unscrew to allow vanes to close further for better spool, run logs after each adjustment. Ideally you want logs of boost, fuelling and MAF readings

Dan,

Ok thanks for that.

Any ideas how I can set the stop screw it to a good starting point position as to not blow the turbo when first starting up? (I've got to replace it as it's snapped from beneath) I've read somewhere that four or five threads should be showing from the bottom of the stop screw where it meets the iron cast that it screws into?

Thanks,

S10EAT

Ok thanks for that.

Any ideas how I can set the stop screw it to a good starting point position as to not blow the turbo when first starting up? (I've got to replace it as it's snapped from beneath) I've read somewhere that four or five threads should be showing from the bottom of the stop screw where it meets the iron cast that it screws into?

Thanks,

S10EAT

I would be making a note of how much is left protruding from the turbo with yours, then compare old vs new when swapping them over, i.e. how many threads are inside the turbo(out of sight)

Should give you a fairly accurate starting point. If in doubt start conservative and unscrew it a bit at a time

Should give you a fairly accurate starting point. If in doubt start conservative and unscrew it a bit at a time

Well I attempted to remove the snapped stop screw and failed miserably. Not only was it extremely difficult to manoeuvre a 3/8 extension attached to a cordless drill under a car with just some small jacks to raise it but, access to the stop screw is fricking ridiculous in one position I had the driveshaft in the way, next was the sump and the only other place I could get to it was at an angle with a bendy extension (not ideal and managed to snap a drill bit).

Only other option I have really is to file down the stop screw as there is roughly enough room to get one in at the top of it. Anyone any other ideas?

Apologies for the rant!

Thanks,

S10EAT

Only other option I have really is to file down the stop screw as there is roughly enough room to get one in at the top of it. Anyone any other ideas?

Apologies for the rant!

Thanks,

S10EAT

Sounds like you're in a right pickle!

I would suggest turbo removal and drill and tap it that way. Turbo shouldn't take you that long to remove if you've only just installed it.

I would suggest turbo removal and drill and tap it that way. Turbo shouldn't take you that long to remove if you've only just installed it.

Similar threads

Model Year 22/23

DIY Matrix (MXB) headlights calibration

- Replies

- 9

- Views

- 4K

- Replies

- 5

- Views

- 4K

- Replies

- 14

- Views

- 9K