More gratuitous parts shots...

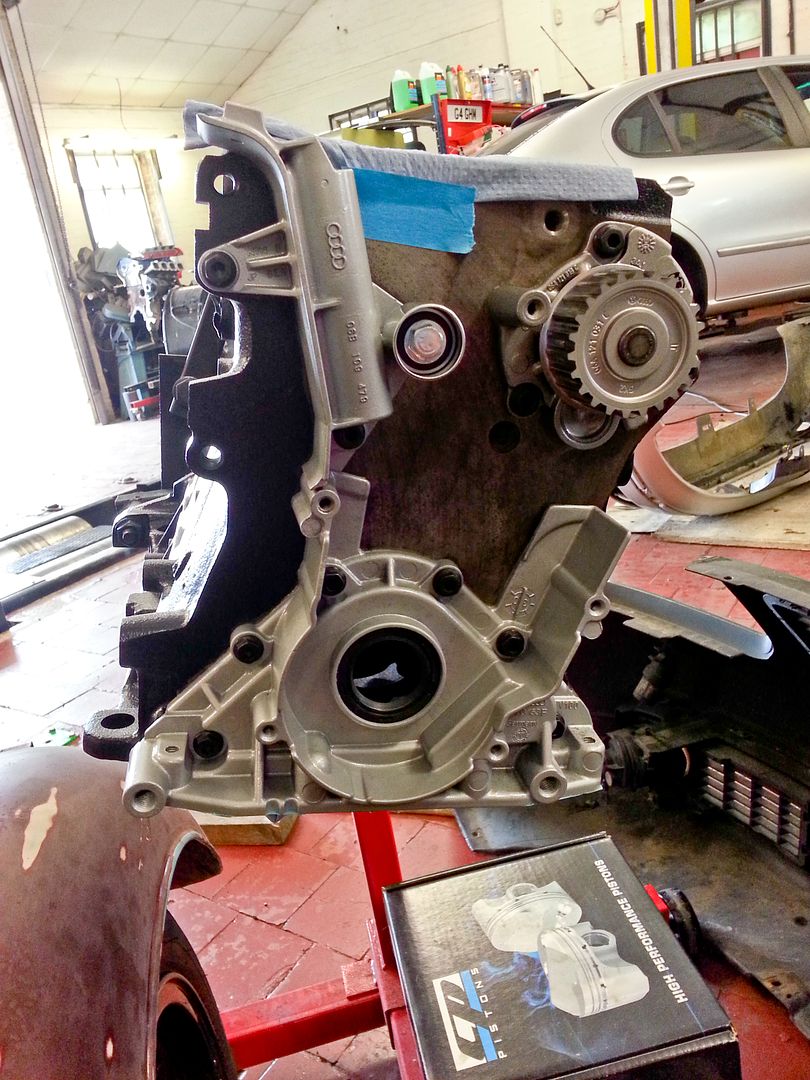

New water pump (I have already lacquered this lol), manual tensioner setup, cam belt, new oil squirters, stat, IE ARP cam pulley bolt and EKagrip cam pulley friction disk

I need to make a spacer for the manual tensioner as the 20v one sticks out further from the head on transverse engine setups...

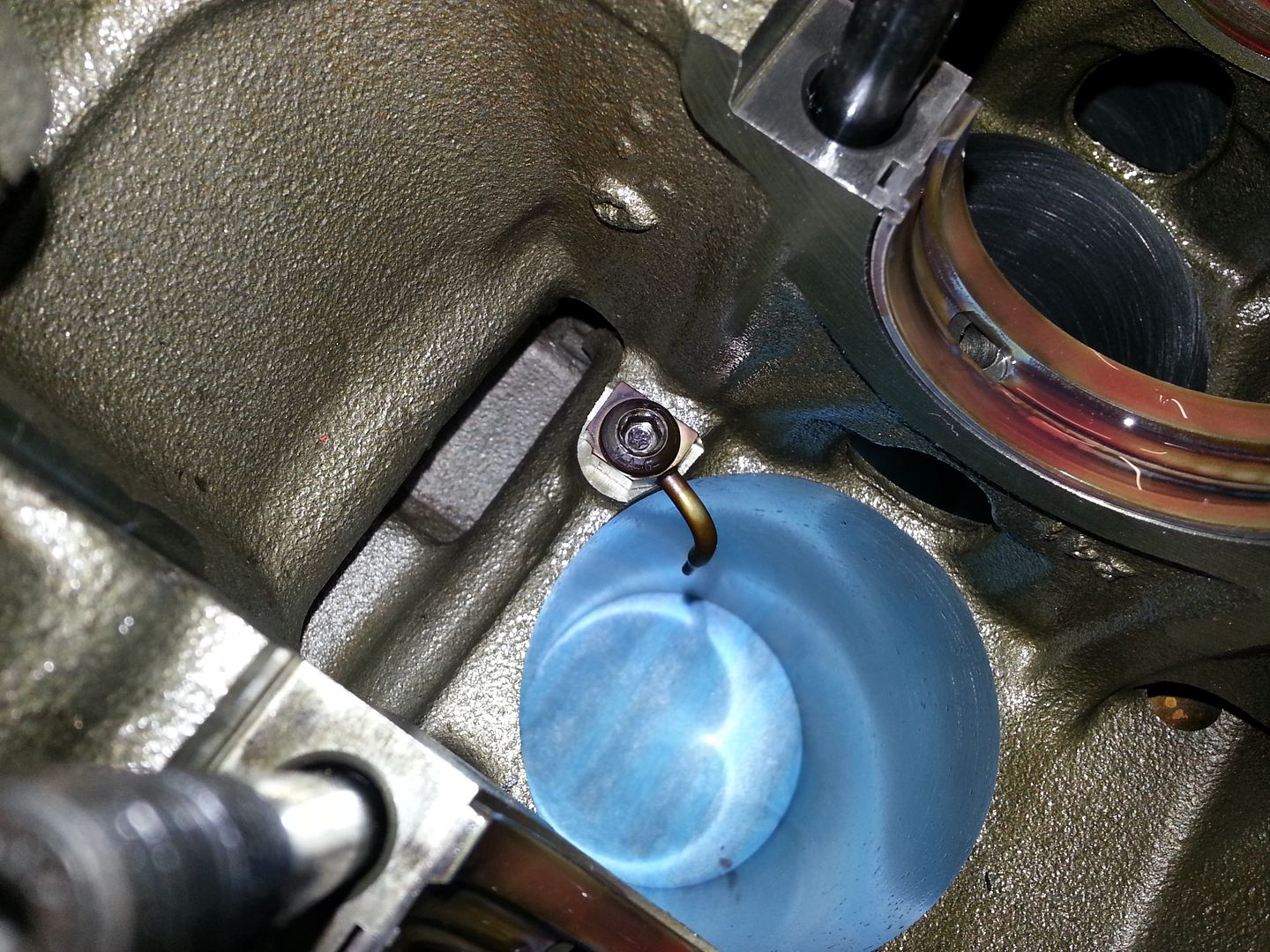

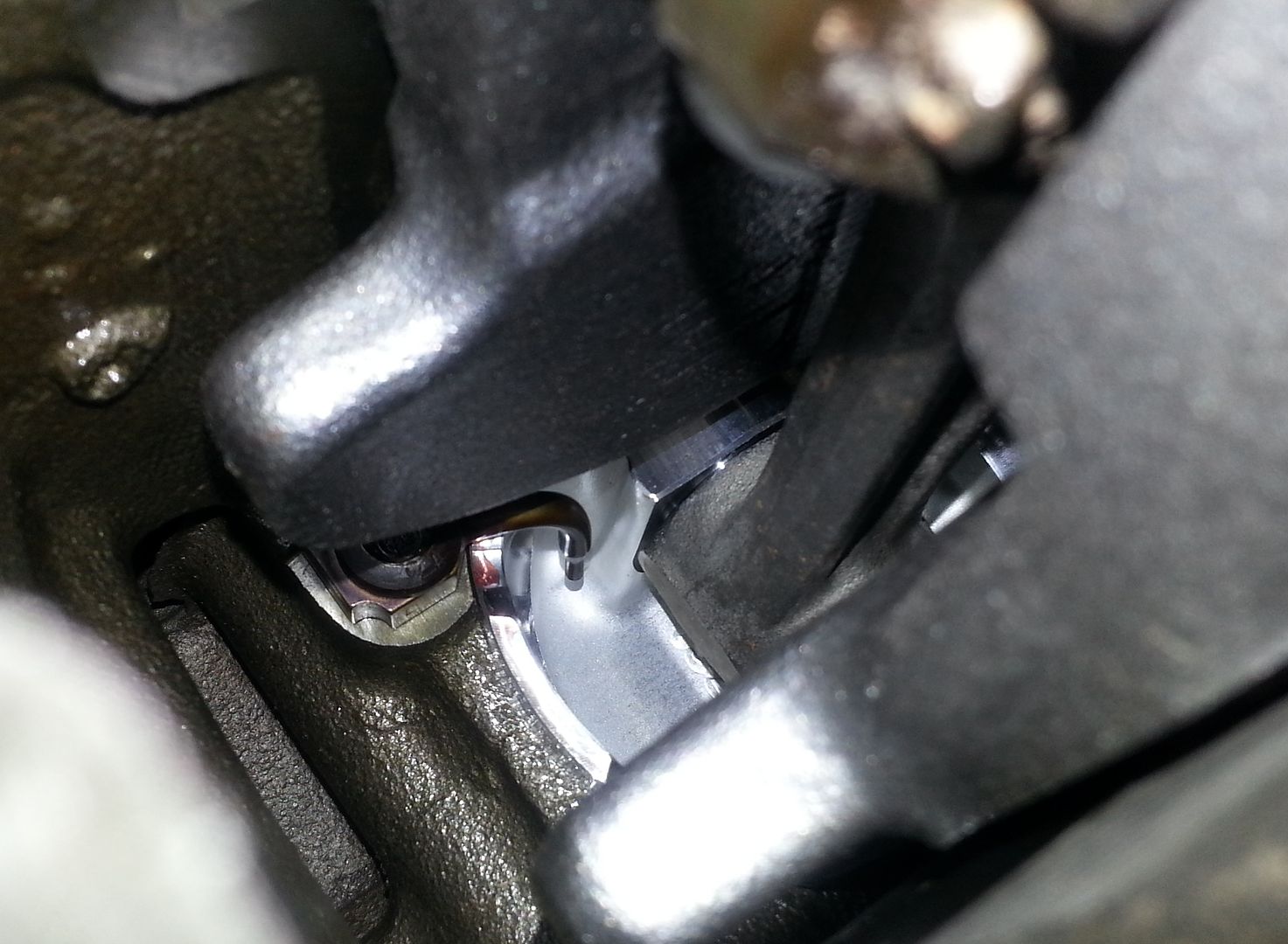

Fitted the new oil squirters (torqued to 27nm)

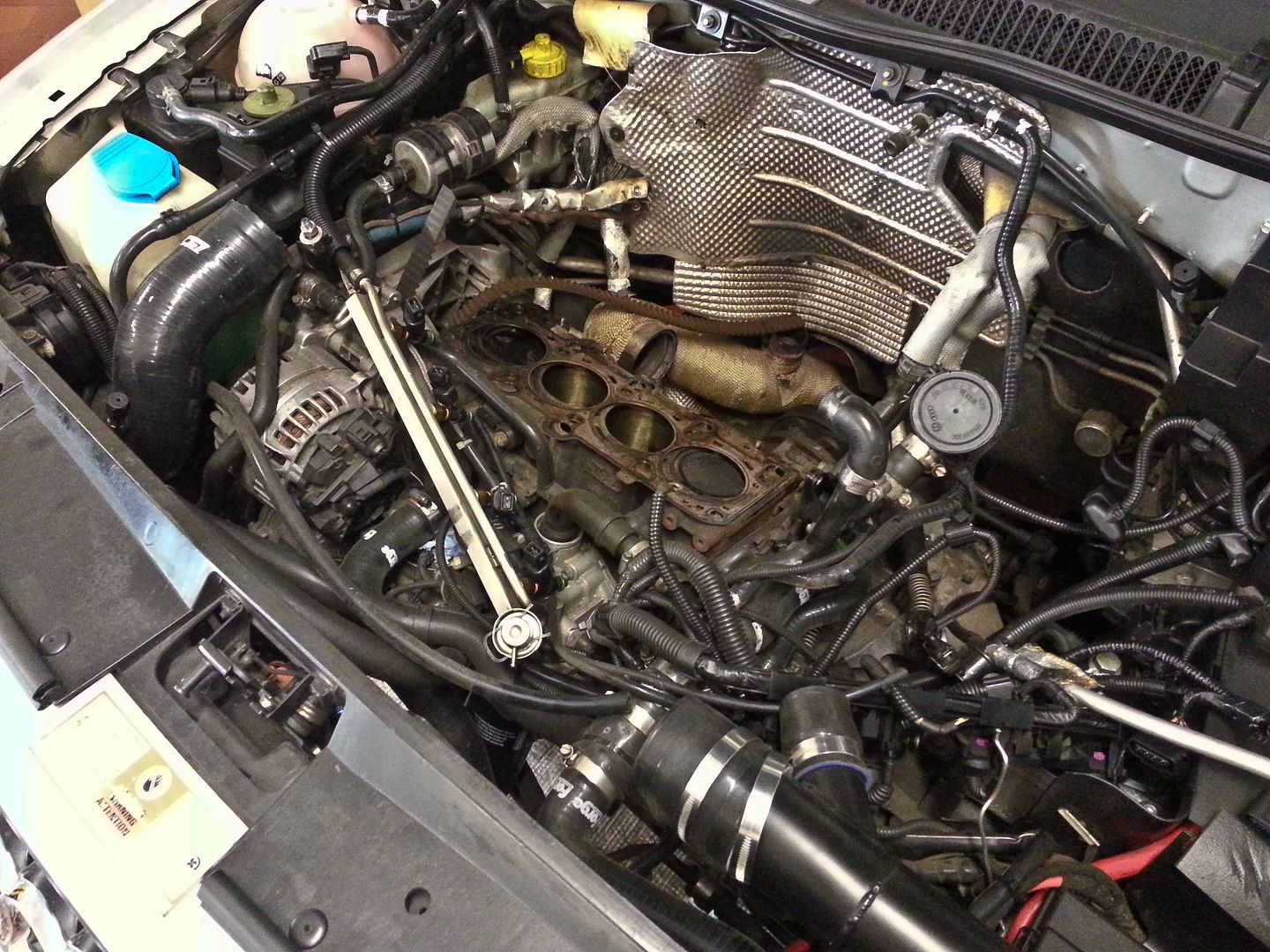

Fitted the water pump, new crank seal into front housing and modified tensioner damper

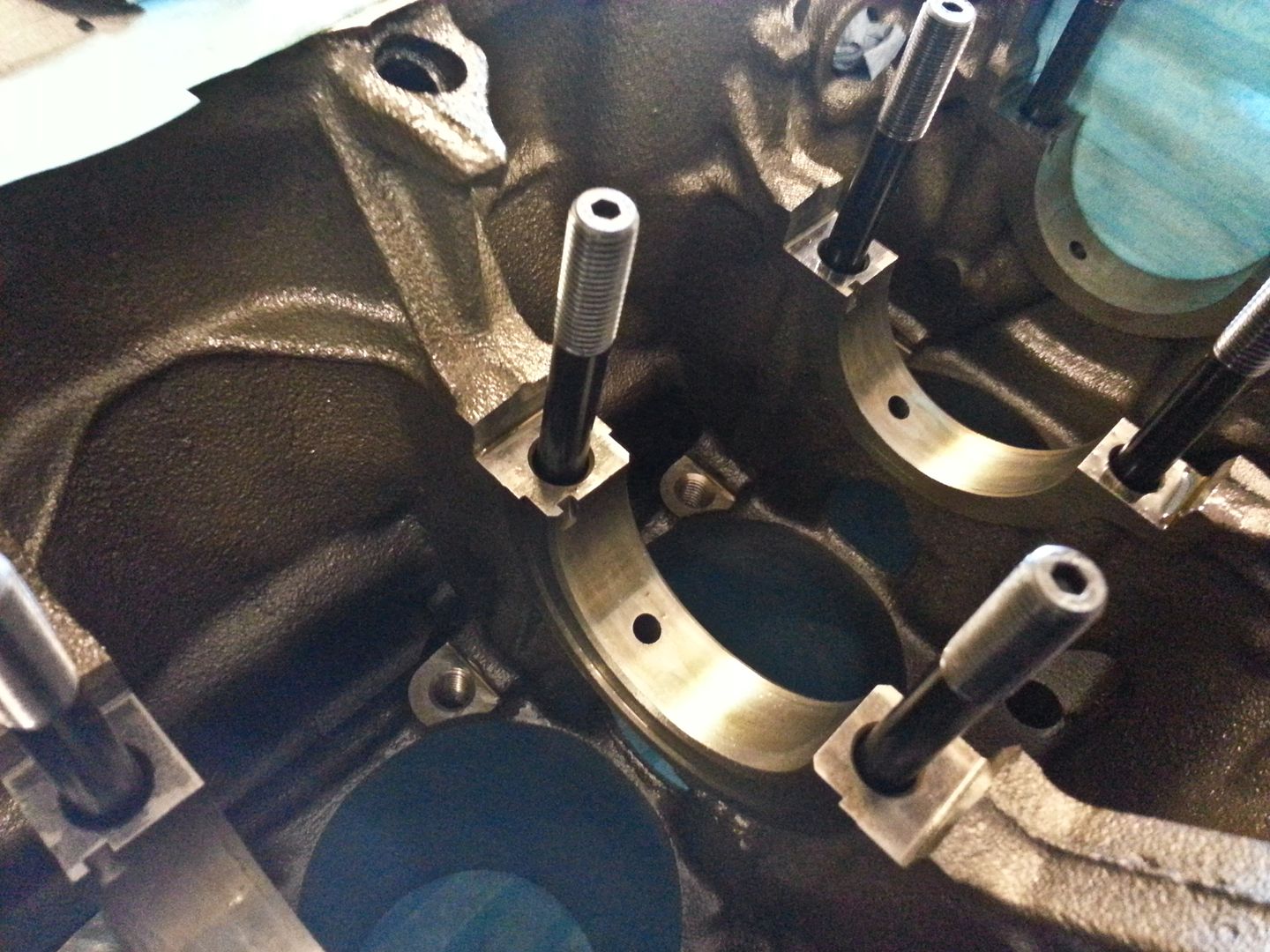

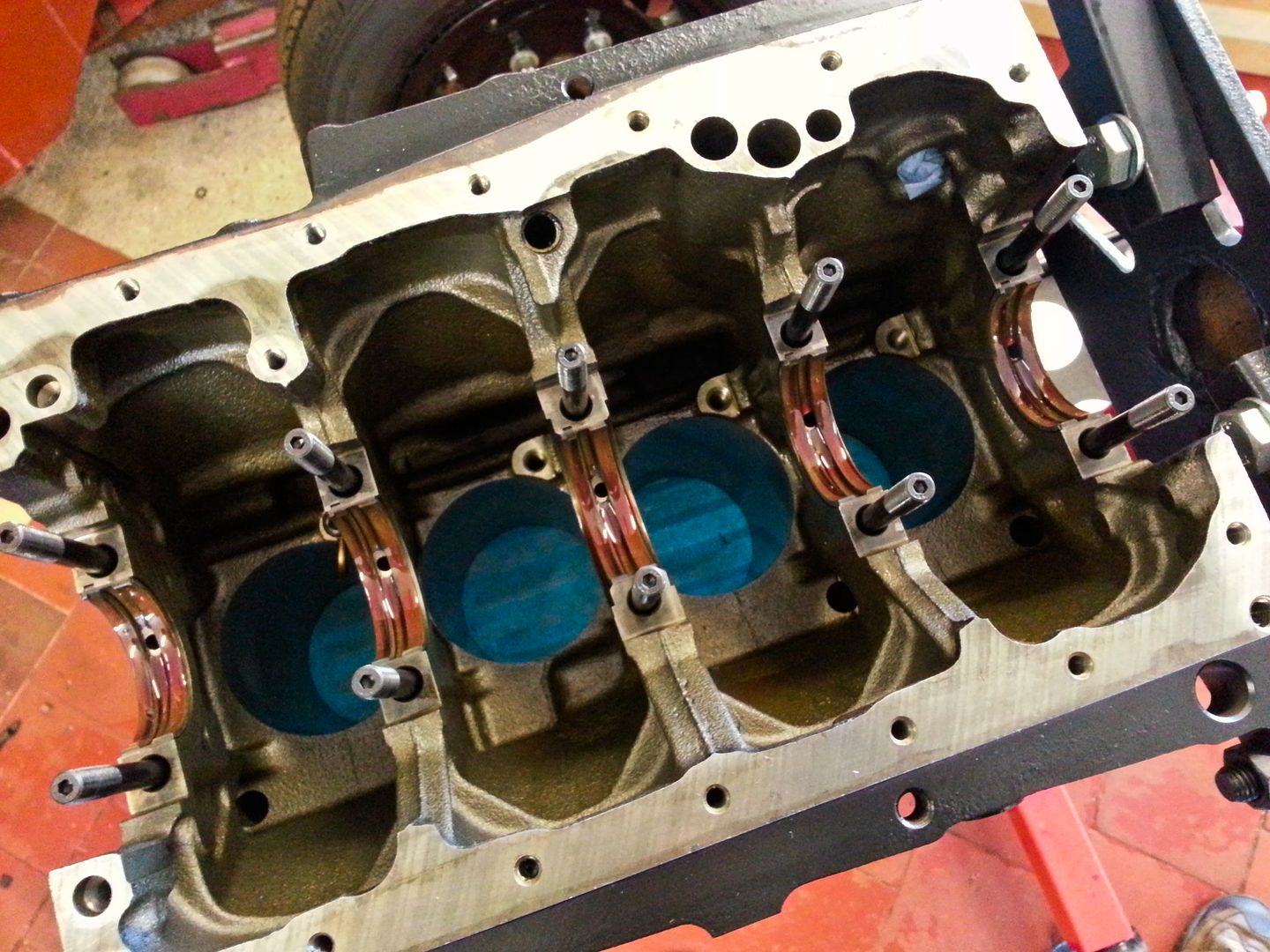

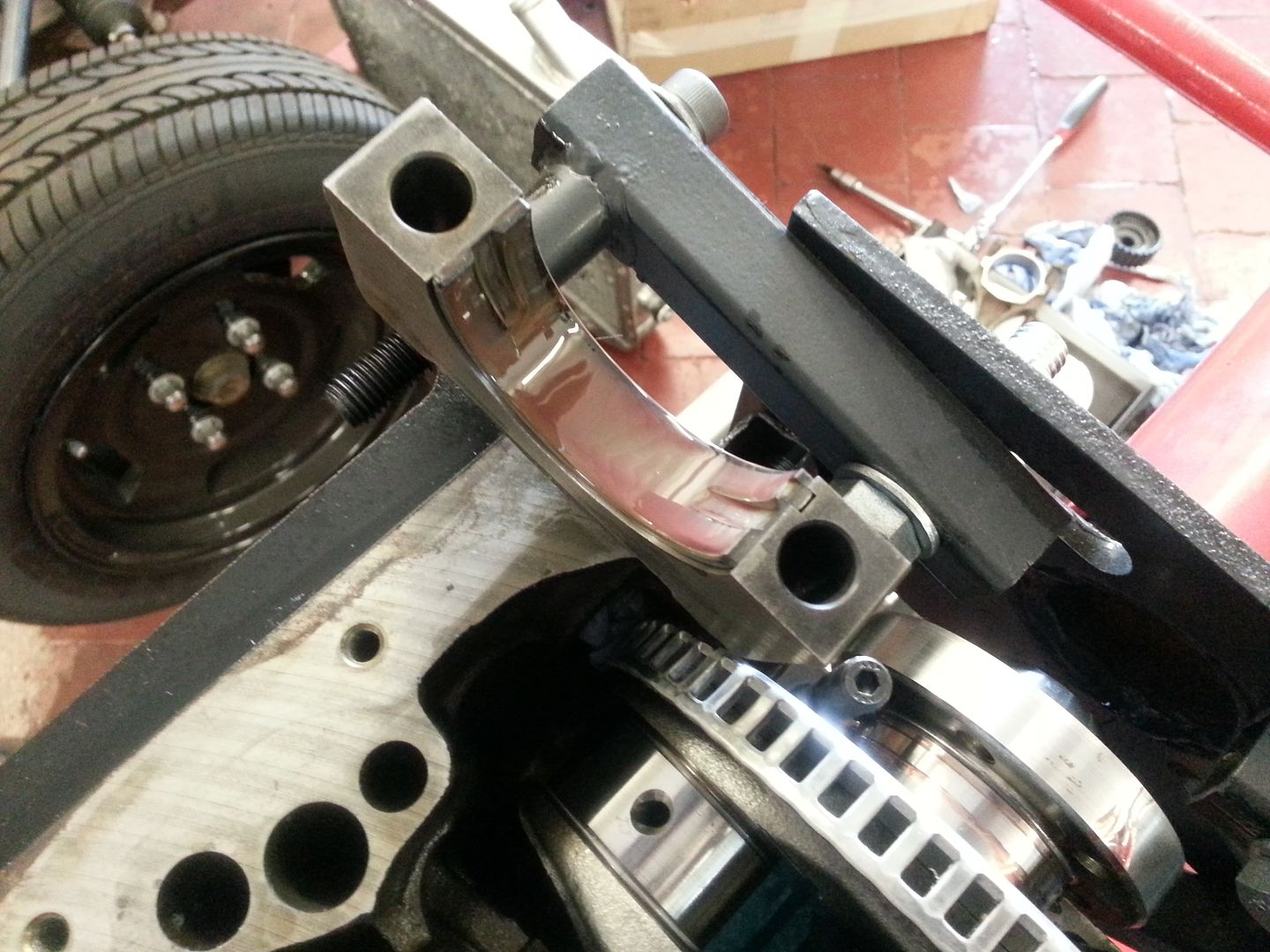

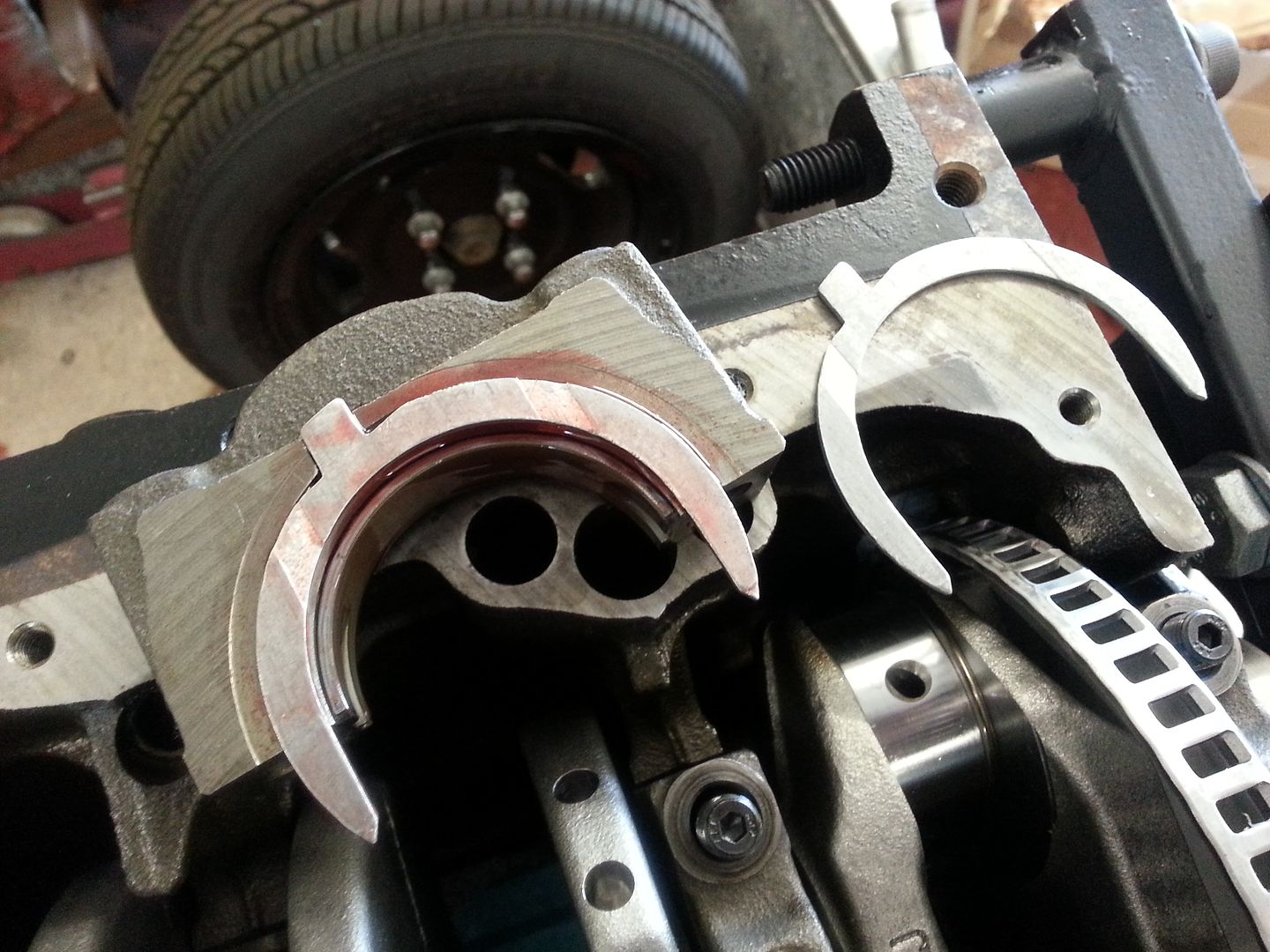

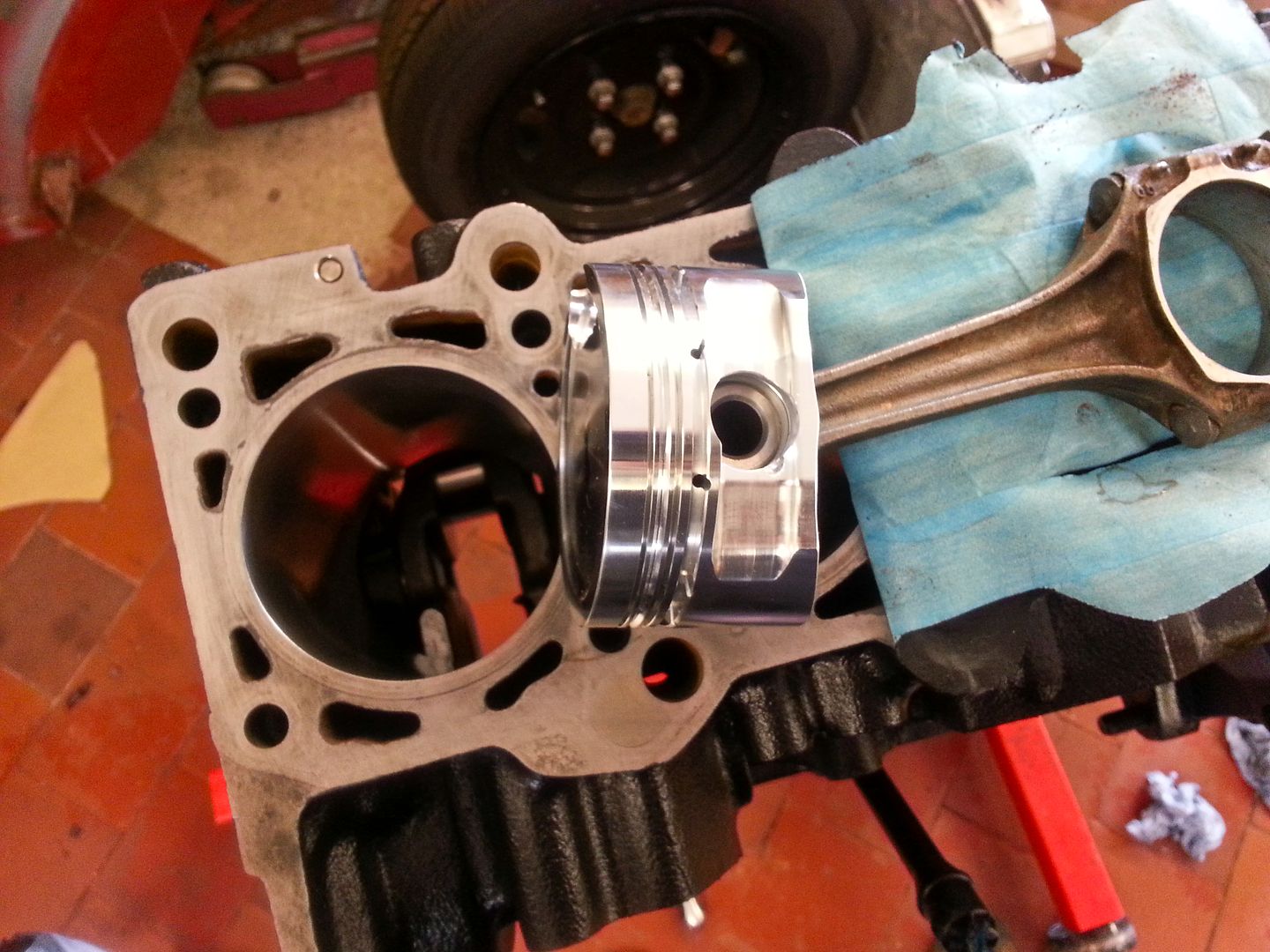

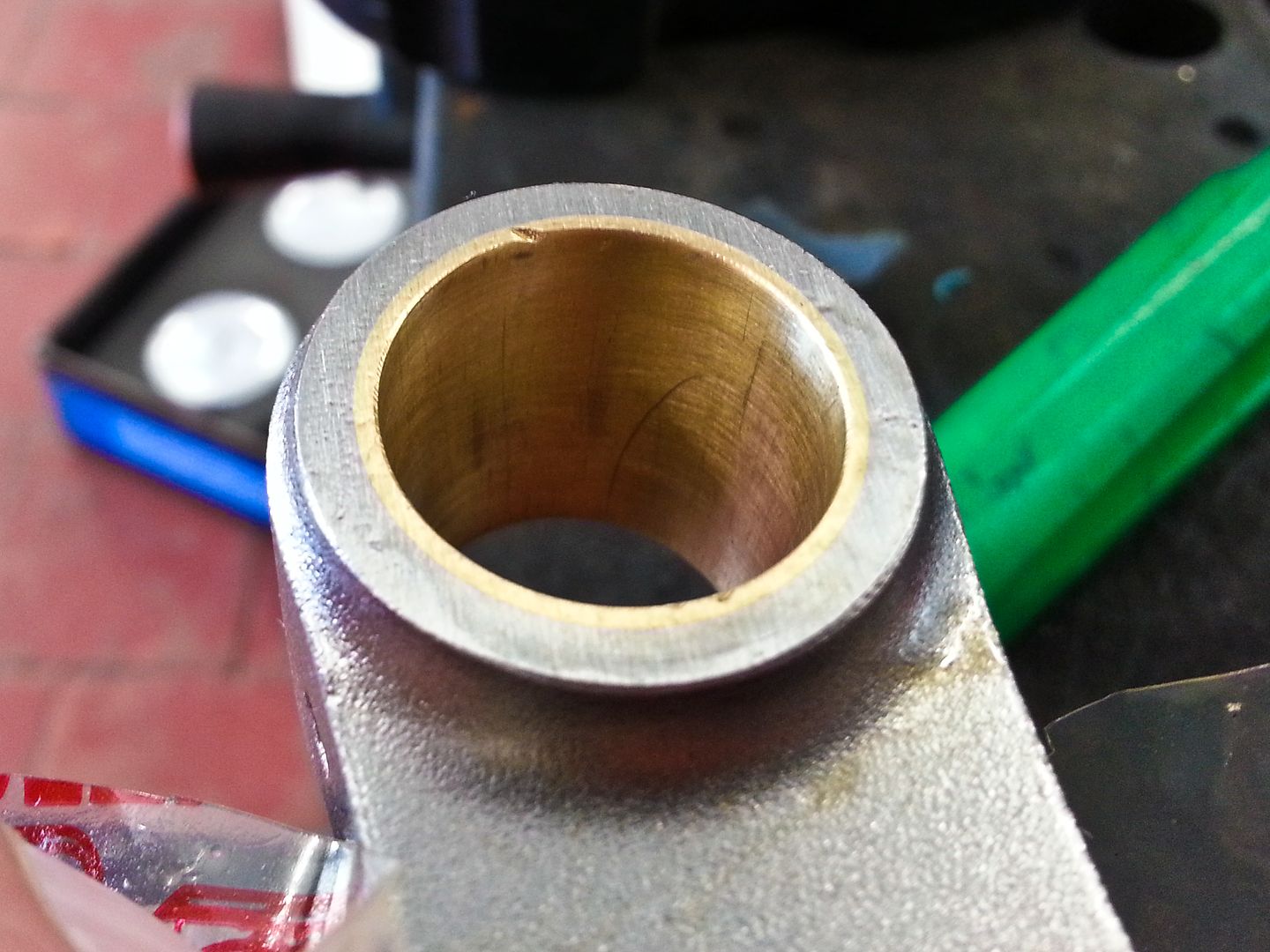

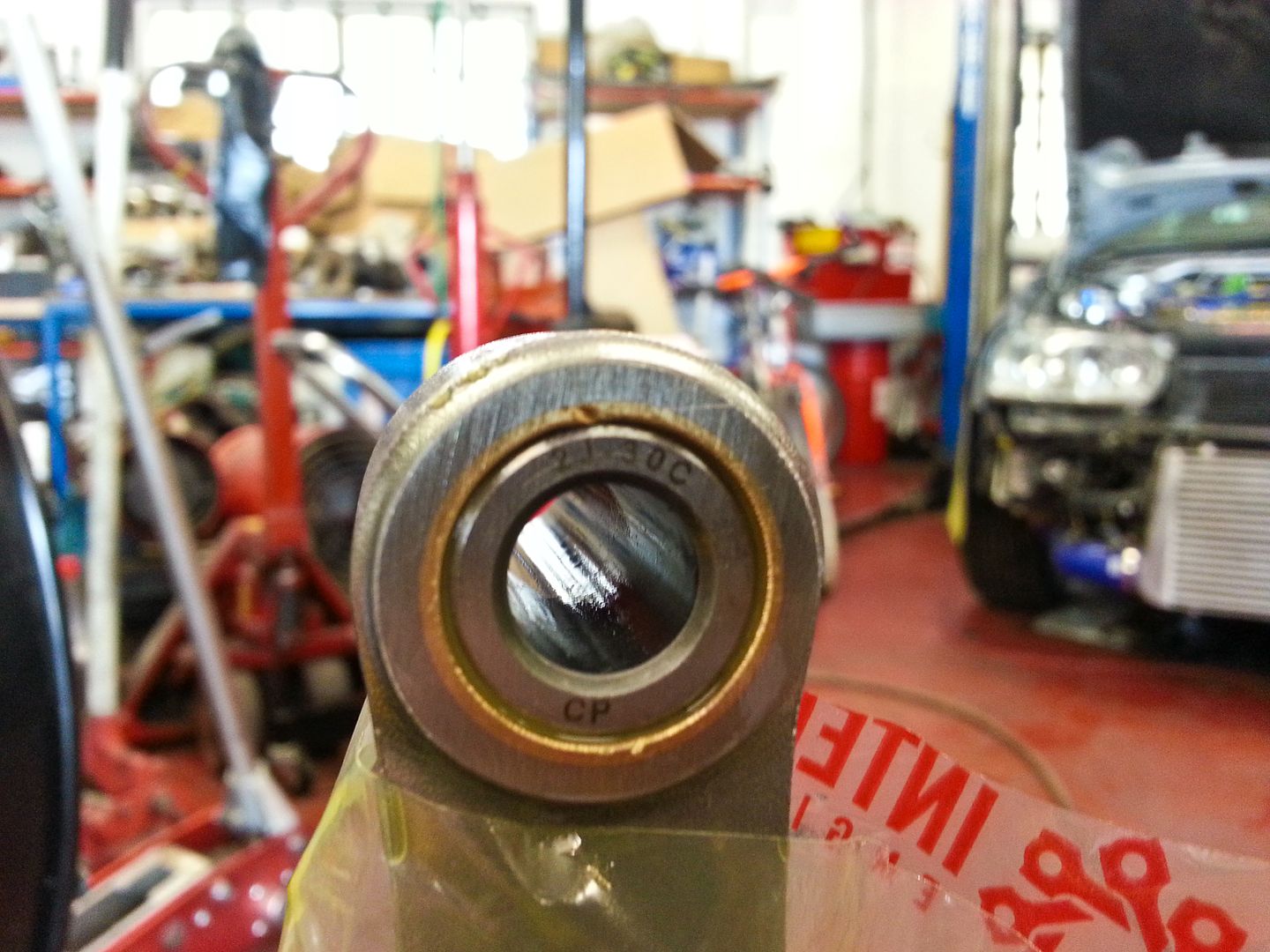

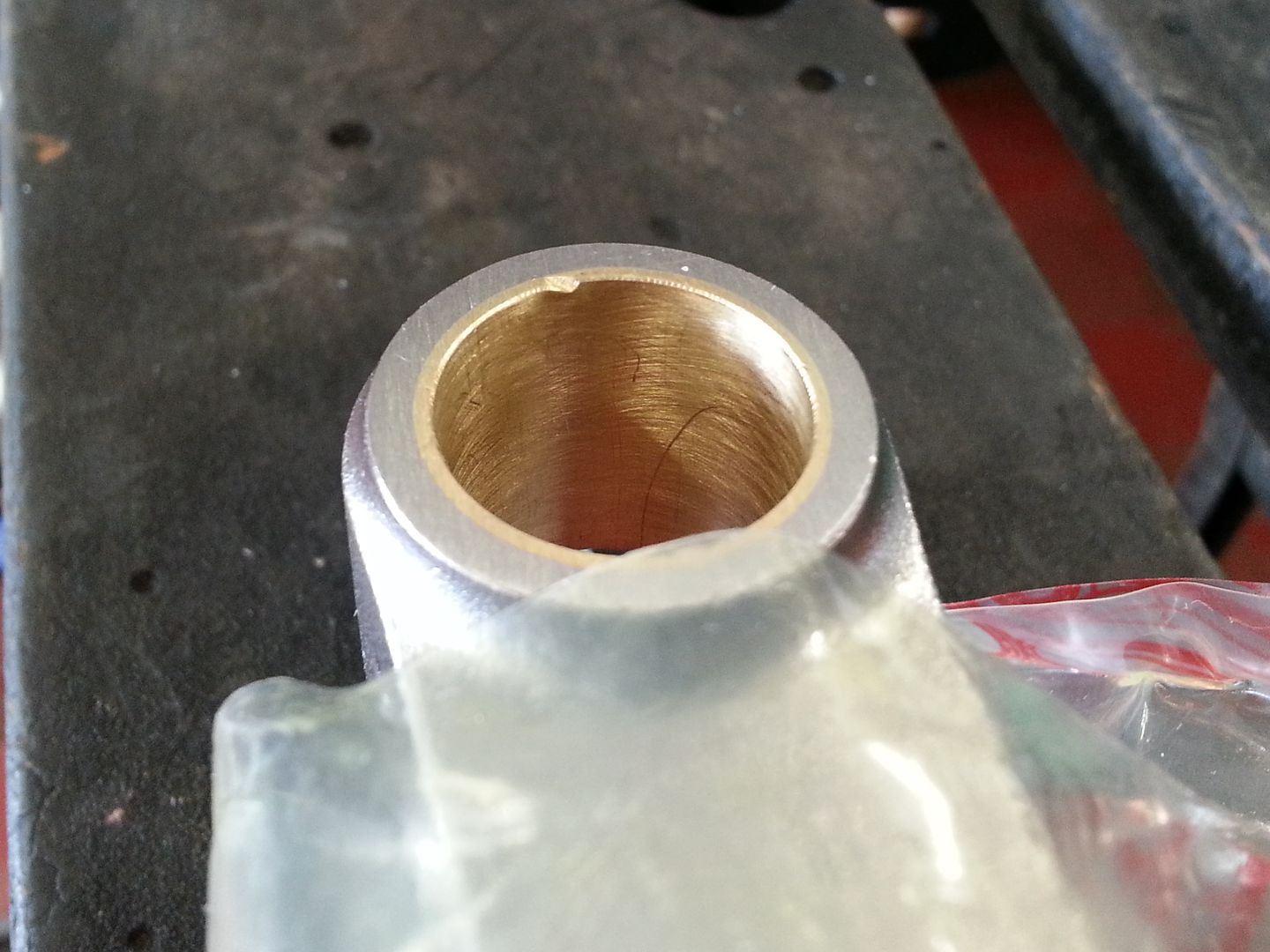

Moved onto checking the pins in the IE rods... the pins need to slide nicely in the small ends... not loose but a small amount of tension when lightly oiled (not build lube)... I had to very lightly hone a couple of the rods until I was happy

One rod looked like it had been knocked when packed and this needed a little more attention with gentle wet and drying to remove the raised part of the bearing from the damage... something to be aware of...

...sorted...

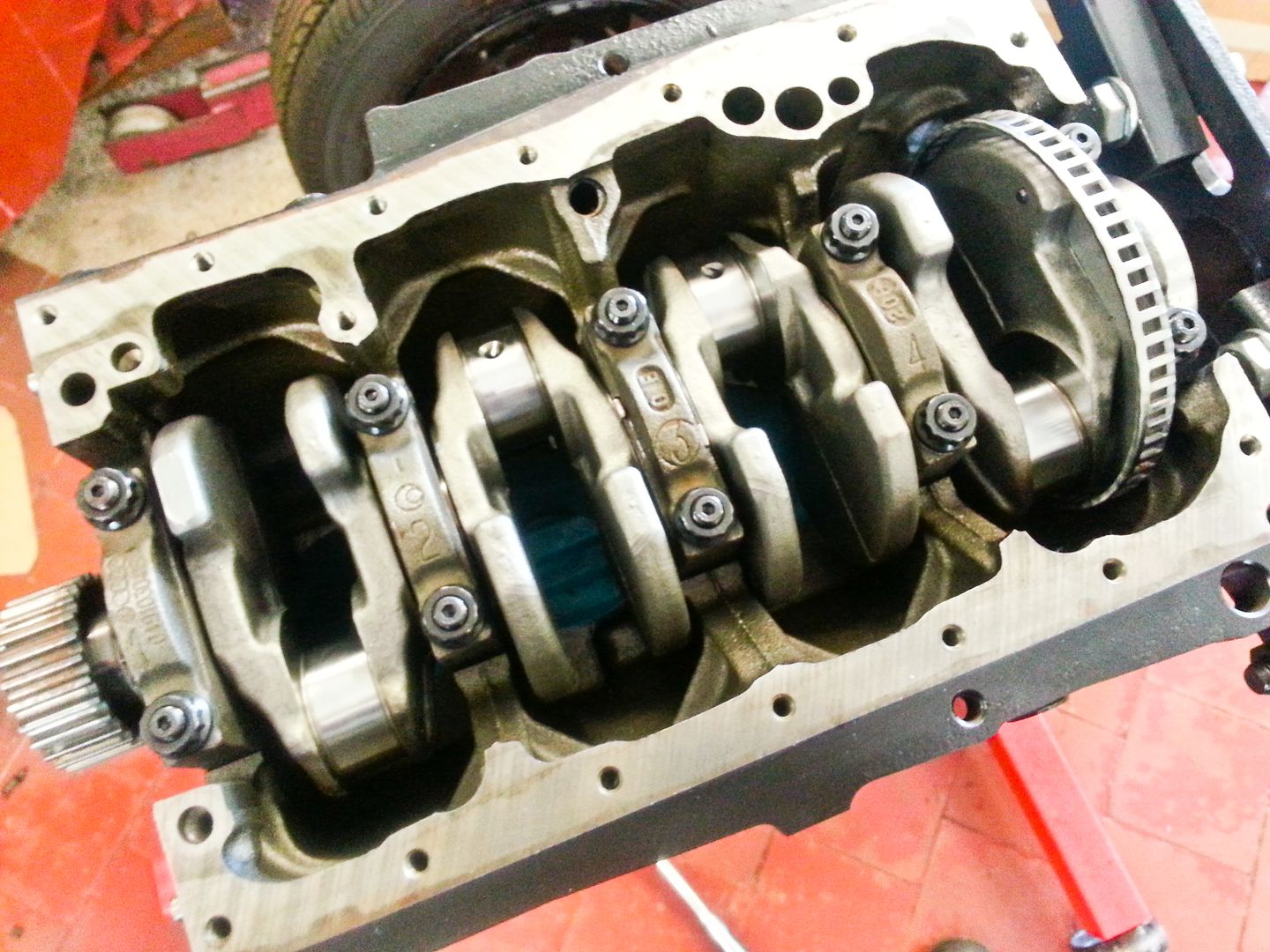

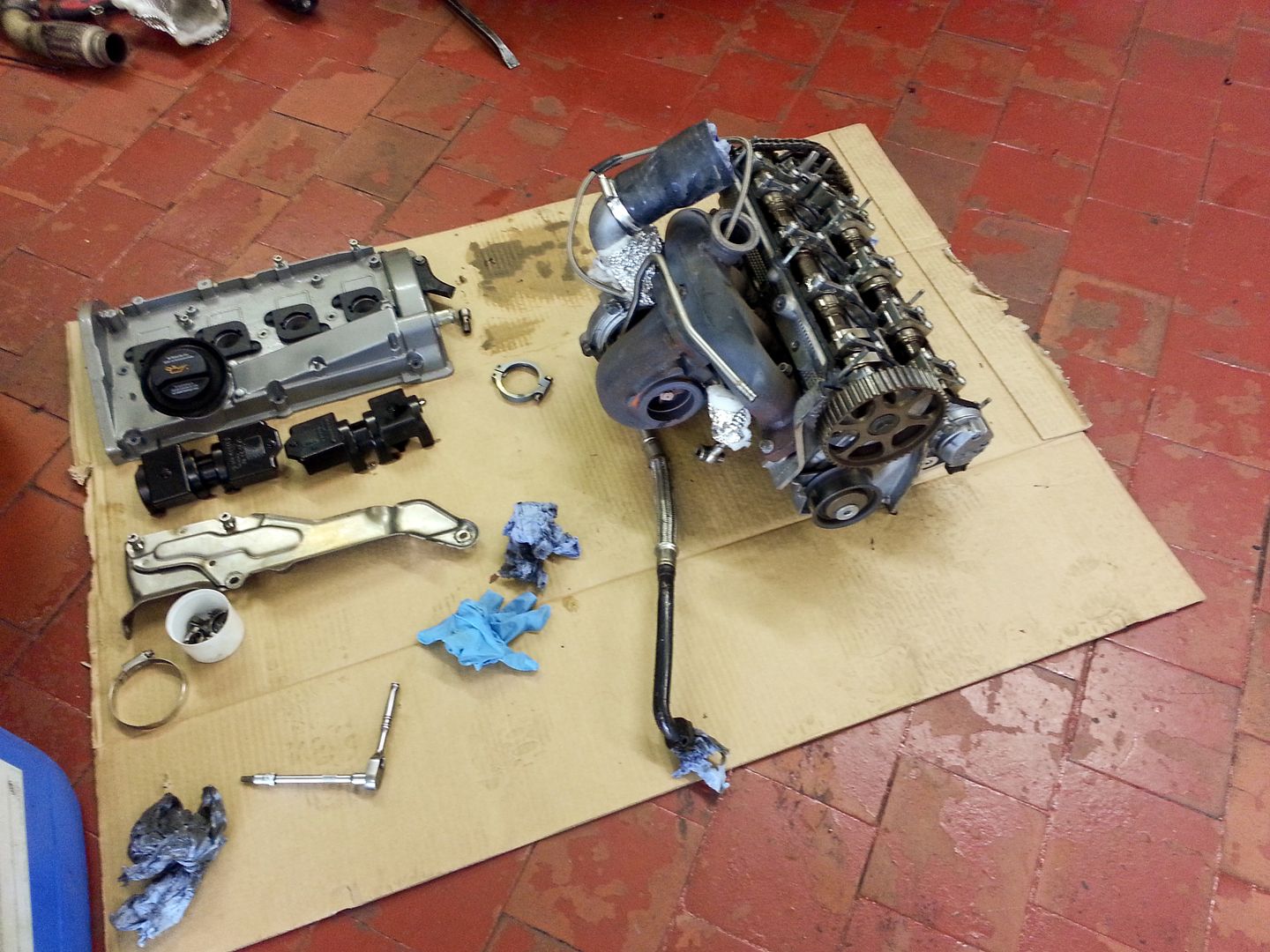

Thats all the rotating assembly parts ready for balancing... will be dropping them off this Friday and I am told they should be ready for the following Friday...

I hope to have the head off the car next weekend (other work permitting)... I have something planned for this that requires it to be off and away for a few weeks... this will at least give me the chance to pull parts I need off the old bottom end to be cleaned, painted and fitted to the new bottom end...

Happy days

<tuffty/>

http://www.seatcupra.net/forums/showthread.php?t=380366