Hi All,

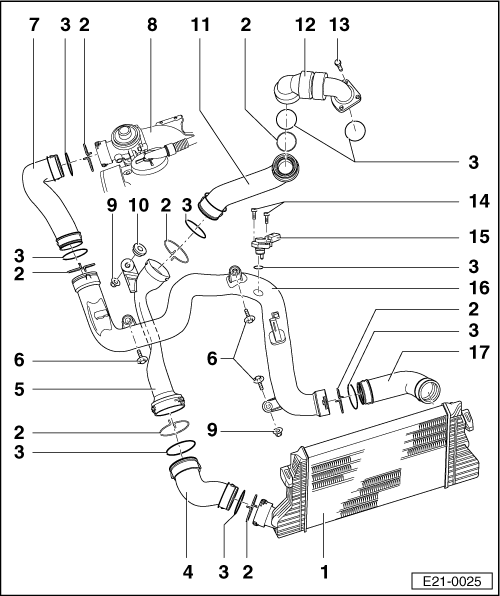

Have had my PD150 Revo'd for about 5 weeks now, and this evening when accelerating I heard a loud pop/bang, puff of smoke out the back and the engine was very very rough. Got the AA out, and appears one of the turbo hoses had popped off ! I guess with the increase in turbo pressure with the remap something had to give eventually. I think its the lower hose, as he reached down to the bottom right of the radiator ?? Is this an simple fix ? I managed to drive it (at 15mph for 2 miles) to the garage, so hopefully they'll get it done

Have had my PD150 Revo'd for about 5 weeks now, and this evening when accelerating I heard a loud pop/bang, puff of smoke out the back and the engine was very very rough. Got the AA out, and appears one of the turbo hoses had popped off ! I guess with the increase in turbo pressure with the remap something had to give eventually. I think its the lower hose, as he reached down to the bottom right of the radiator ?? Is this an simple fix ? I managed to drive it (at 15mph for 2 miles) to the garage, so hopefully they'll get it done