Hi guys & gals,

Here is my guide for removing and refitting a new water pump/thermostat unit to the 1.4Tsi engine. My engine code is CZEA but this proceedure will be the same for other variants.

Tools required:

T25, T30 & T40 Torx bit & driver

Allen/Hex 10 bit & driver

Adjustable grips

Flat bladed screwdriver

Phillips screwdriver

Tub for collecting coolant

Torque wrench

Jack & axle stand, or access to a lift/ramp

Parts:

New unit (P/N 04E121600CR)

New drive belt (P/N 04E121605E)

Coolant (G12 Evo/ G13)

Getting started

Firstly comfirm the leak/failure is in fact the unit itself. The unit houses the thermostat and waterpump, both of which can fail seperately or can leak. In my case the unit was leaking coolant and I spotted some sitting on the top of the unit:

To start, you need to remove the undertray if one is present. I have covered this already in this guide here:

www.seatcupra.net

www.seatcupra.net

Once that has been removed, you need to drain the coolant. The easiest way of doing this is from the bottom right side of the radiator. There is a connector secured with a metal clip. Pry out the clip with the flat bladed screwdriver and then pull the connector apart. Once you do this coolant will flow out of the radiator and the pipe. This is where the tub comes in to collect the coolant. As it is draining remove the cap from the expansion tank to aid removing the coolant. If you can, use something that will allow you to measure the amount of coolant that you remove. This is to ensure you put back the correct amount when refilling the system at the end of the job.

Connector with clip secured:

Clip unsecured:

Coolant flowing out:

With this done, you need to start dis-assembling parts around the unit at the top of the engine.

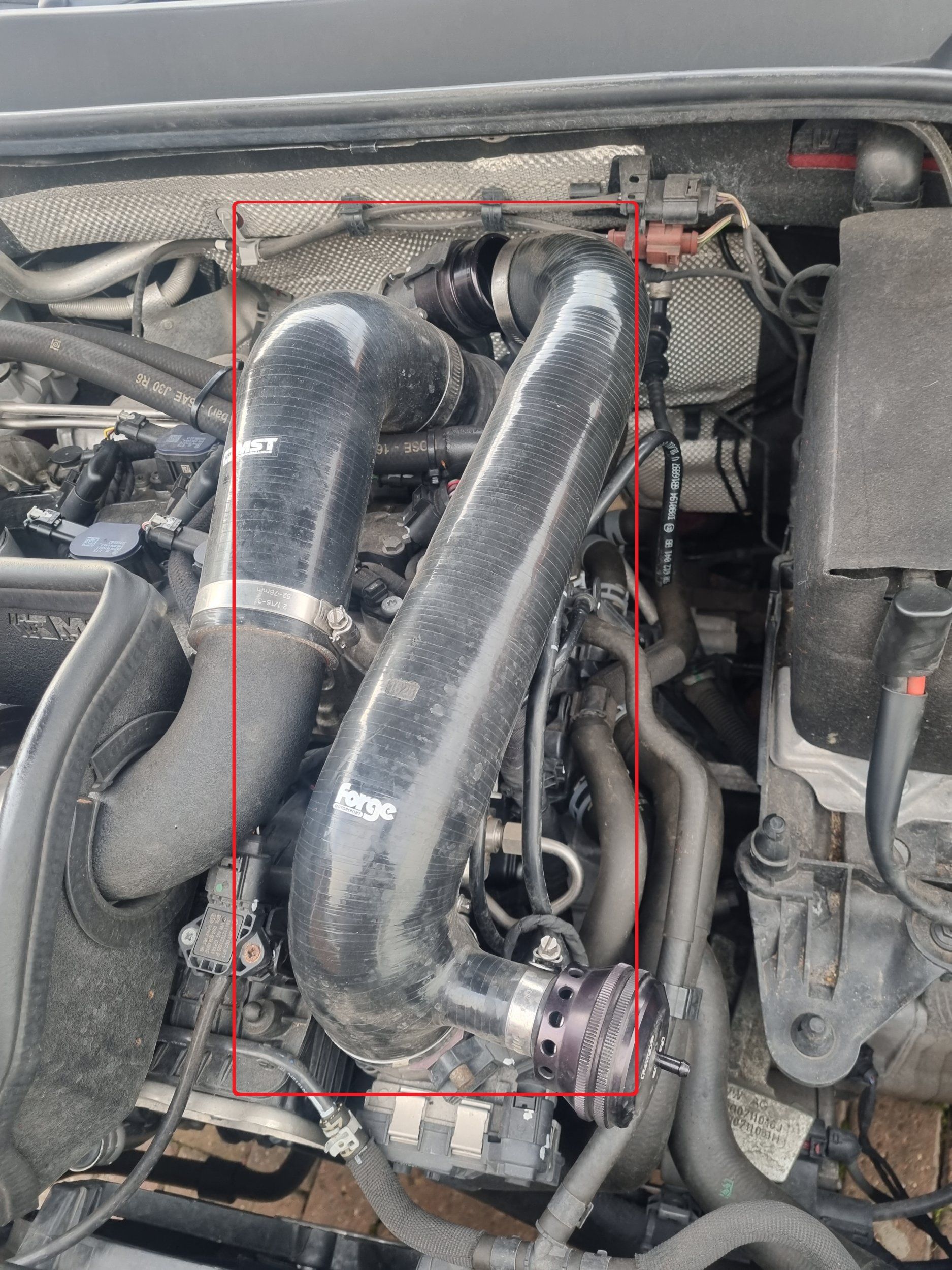

Start with removing the air filter pipes that run to the back of the engine. They are secured with clips, use the adjustable grips to loosen them. I have an intake kit on my engine so I can't show photo's of this however the area I've highlighted in this photo show where the pipes should be removed from:

With the intake pipes removed, you next need to remove the pipe that goes from the side of the engine to the turbo, then the plastic part attached to the turbo at the back. Both are secured with 2 Torx 30 screws. On the pipe there is a smaller pipe attached with a clip, remove this by squeezing the tabs together.

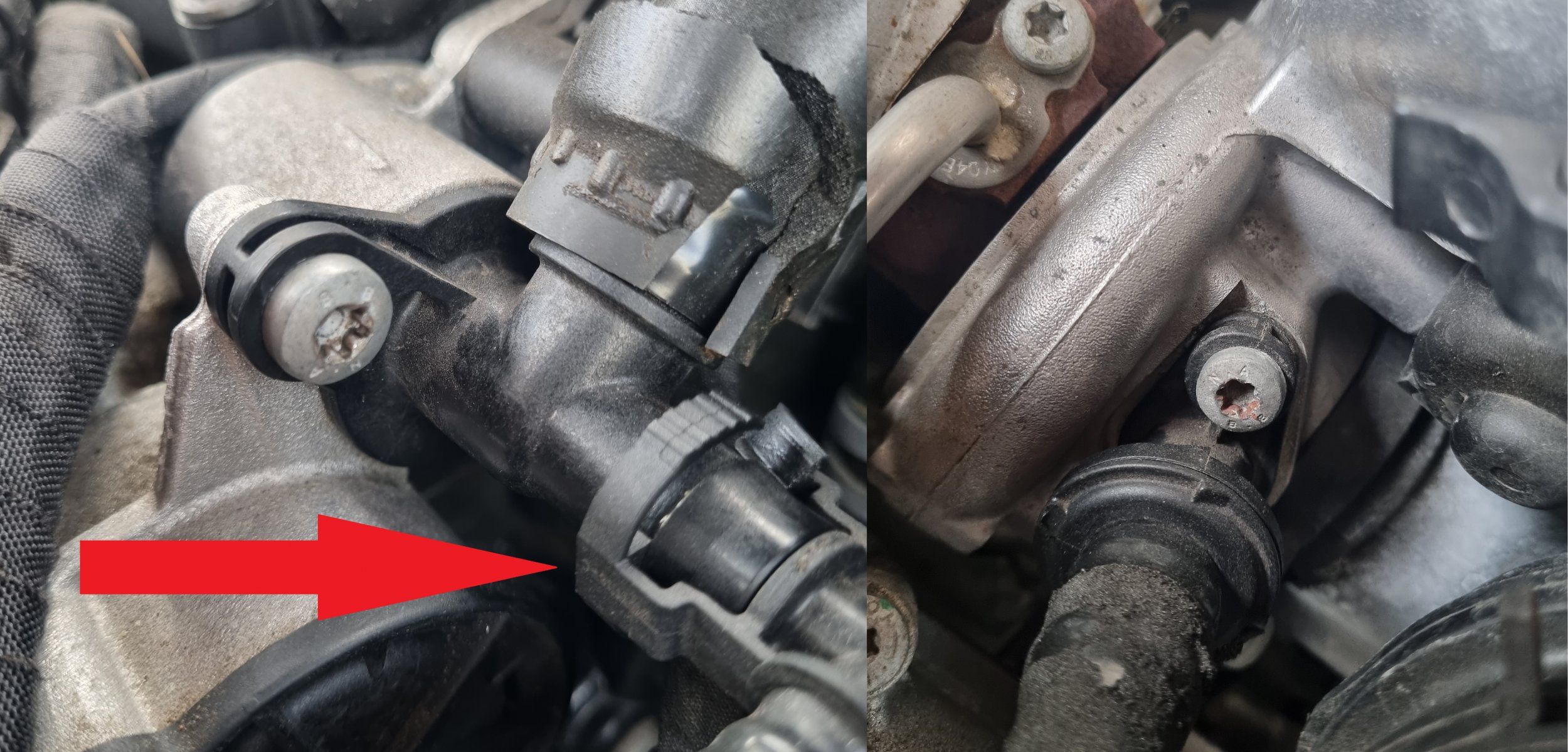

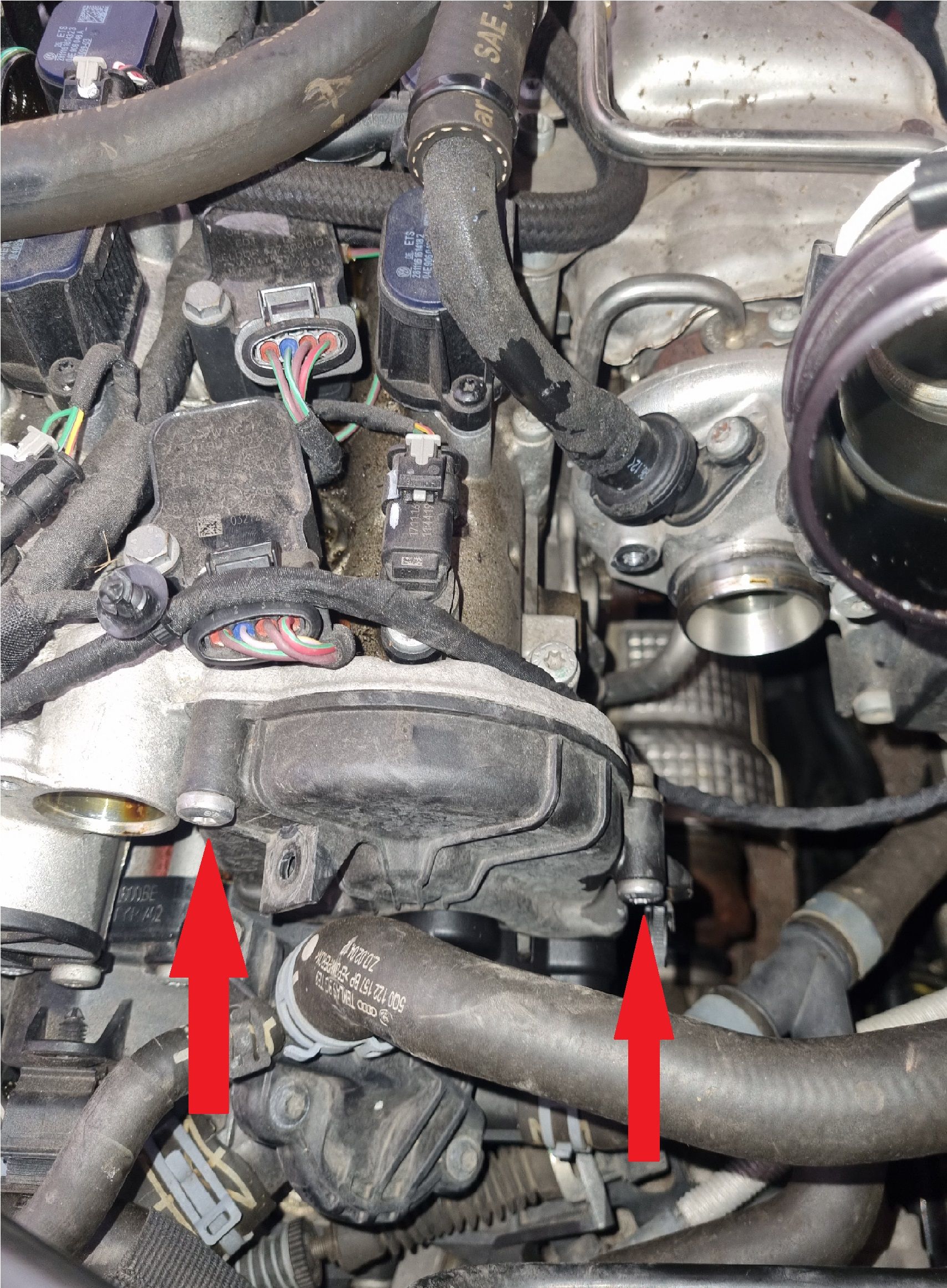

Pipe screws, smaller pipe to be removed highlighted by red arrow:

Screws for plastic part on turbo. The front one is in a tight position to get to so use of a skinny driver will be required. The rear one is located down the back. Red arrows show their location:

With these removed you should be left with this:

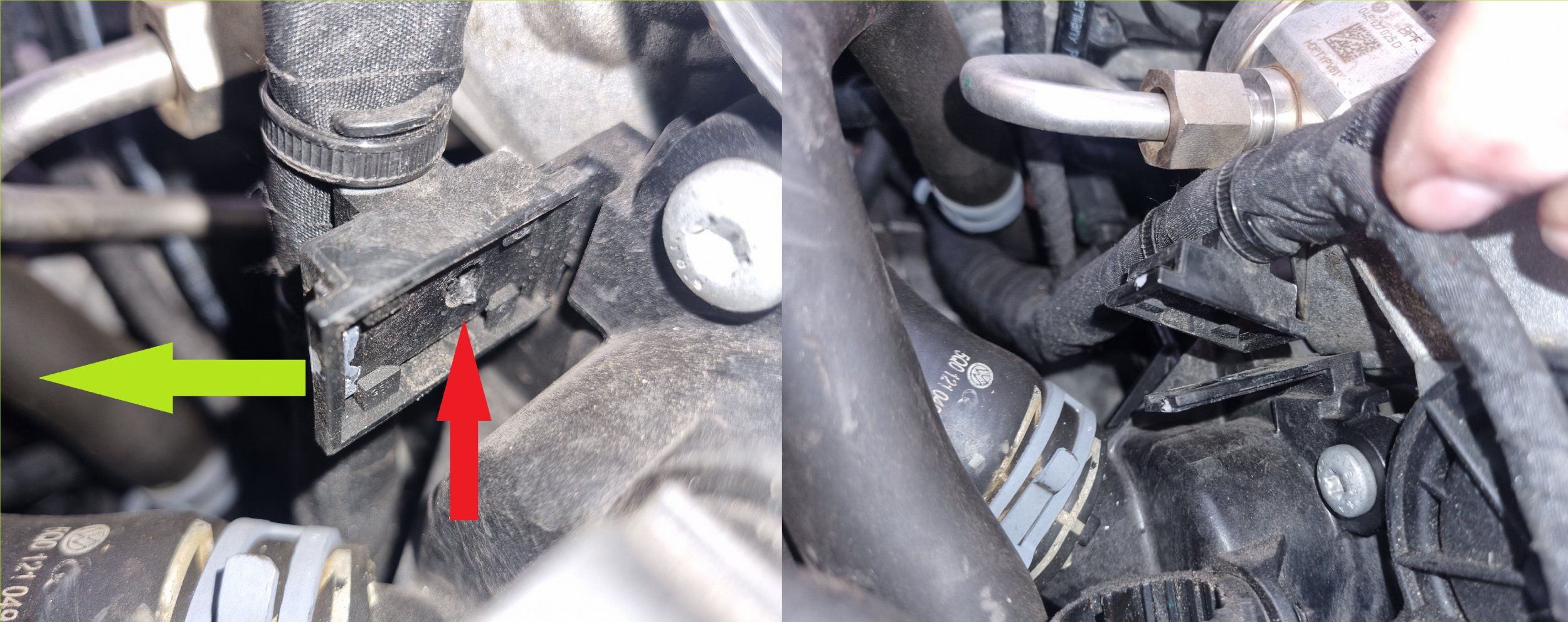

Next you need to move the wiring loom out of the way, and then start removing the 5 pipes attached to the unit. The wiring loom isn't very flexible but it is attached to the unit with 2 small clips on the right and a bigger clip on the left (as can be seen on the above picture). The bigger clip needs to be disconnected from the back with a screwdriver. Try and move the wiring onto the top of the engine to keep it out of the way.

Back of bigger clip, push the driver into the small hole (red arrow) and slide the clip off the bracket in the direction of the green arrow:

Now use the adjustable grips to remove the clips off the 5 pipes connected to the unit. There are 2 big pipes towards the front of the car, 2 medium sized towards the rear and a small one on top. As you remove these pipes, try to move them somewhere high to avoid un-necassery coolant loss. You will loose some coolant while moving these so put something on the floor to catch this. Keep the tub under the radiator while doing this as more coolant will flow out.

When you remove the clips the pipe will be stiff to pull off. Use the grips to lightly clamp around the end of the pipe and twist it till it moves easily. You will then be able to pull the pipe off with relative ease.

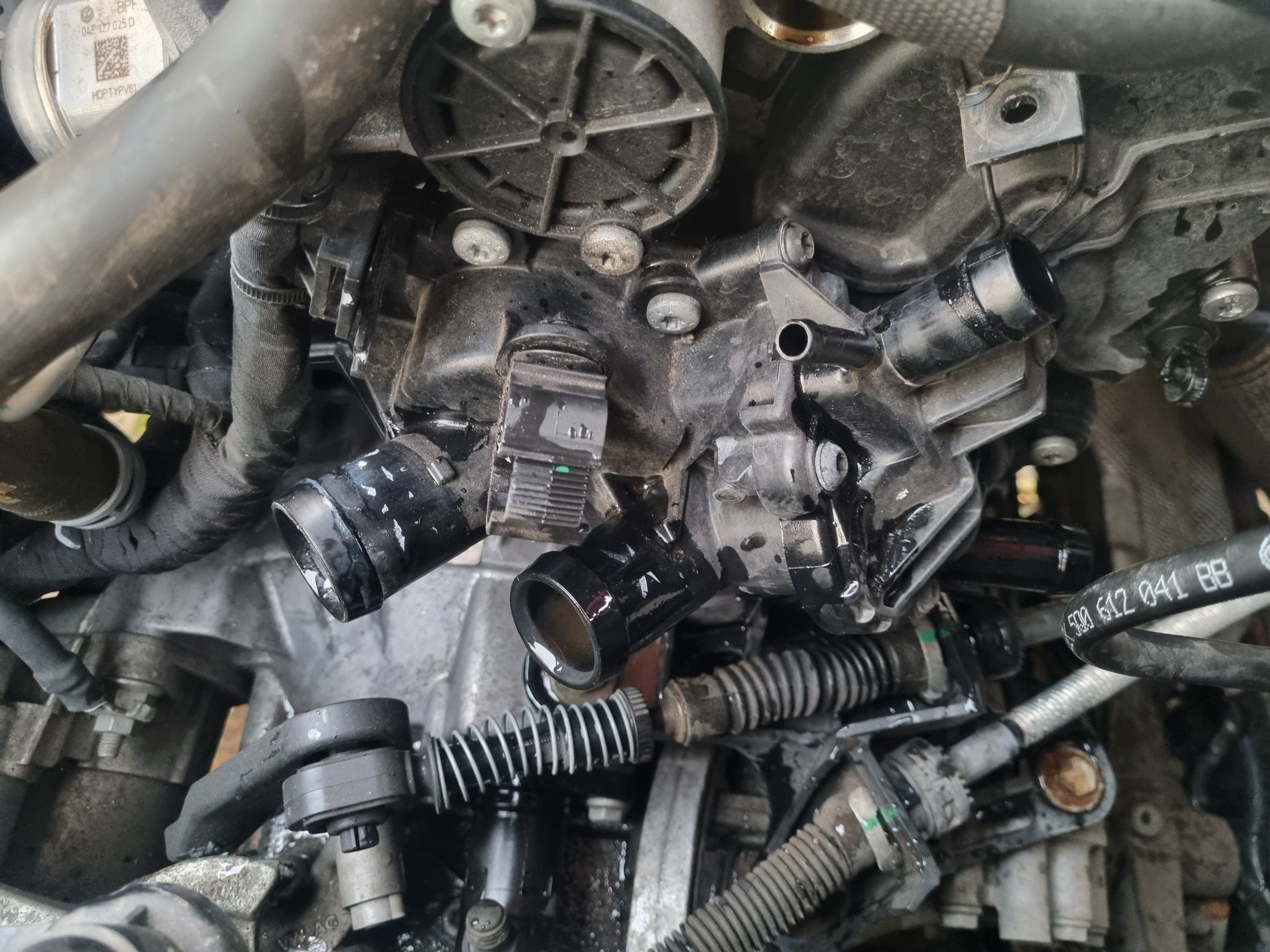

All pipes removed:

Next, remove the cover at the top of the engine next to the turbo. This covers the gear that drives the belt for the water pump. It is secured with 2 T30 screws (red arrows):

Removing the unit

The thermostat/pump unit is secured with 5 T30 screws. 2 are on top, 2 are at the ends and 1 is below. With these removed the pump may be stuck to the side of the engine so pull it lose and remove it. The drive belt will slip off the cam gear. The old gasket may stick and will leave residue stuck to the engine, remove this with a scouring pad until the metal is clean.

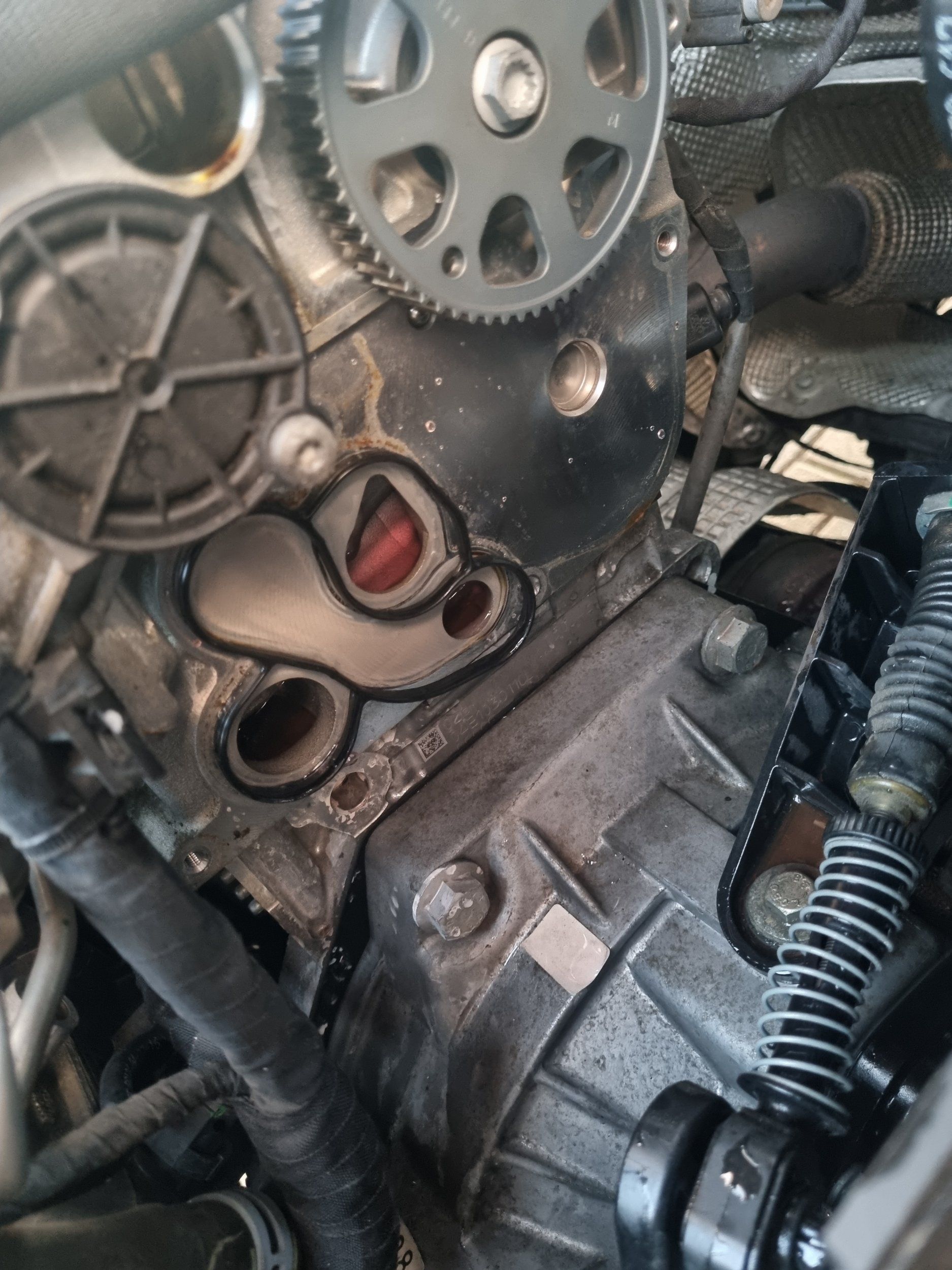

Pump removed, old gasket stuck to engine. Note in this picture you can see rust marks where the old unit has been leaking (next to the top of the gasket):

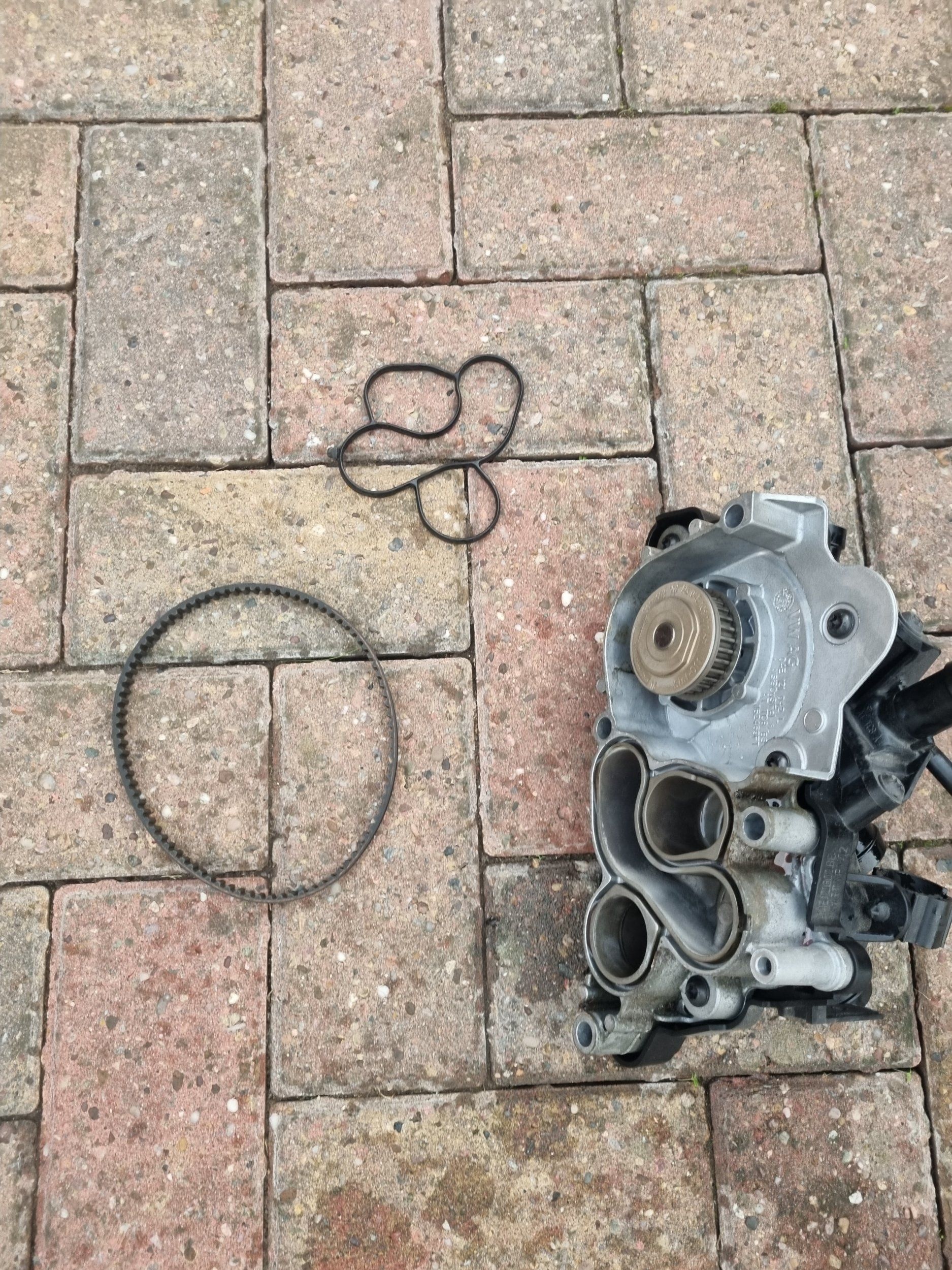

Old unit with drive belt and gasket (marks around top of the unit indicate where the leak was):

Area cleaned, ready for new unit to be fitted:

Fitting the new pump

With the area cleaned, it is time to fit the new pump unit. Before fitting, make sure the gasket is seated correctly in the grooves and apply a film of coolant to it. Put the new drive belt around the pump gear and slide it onto the drive gear as you put the unit into position on the engine. Ensure the belt position central to the drive gear. Once in position, put in the 2 bolts on top and the 2 bolts on the sides by hand, and tighten them by hand.

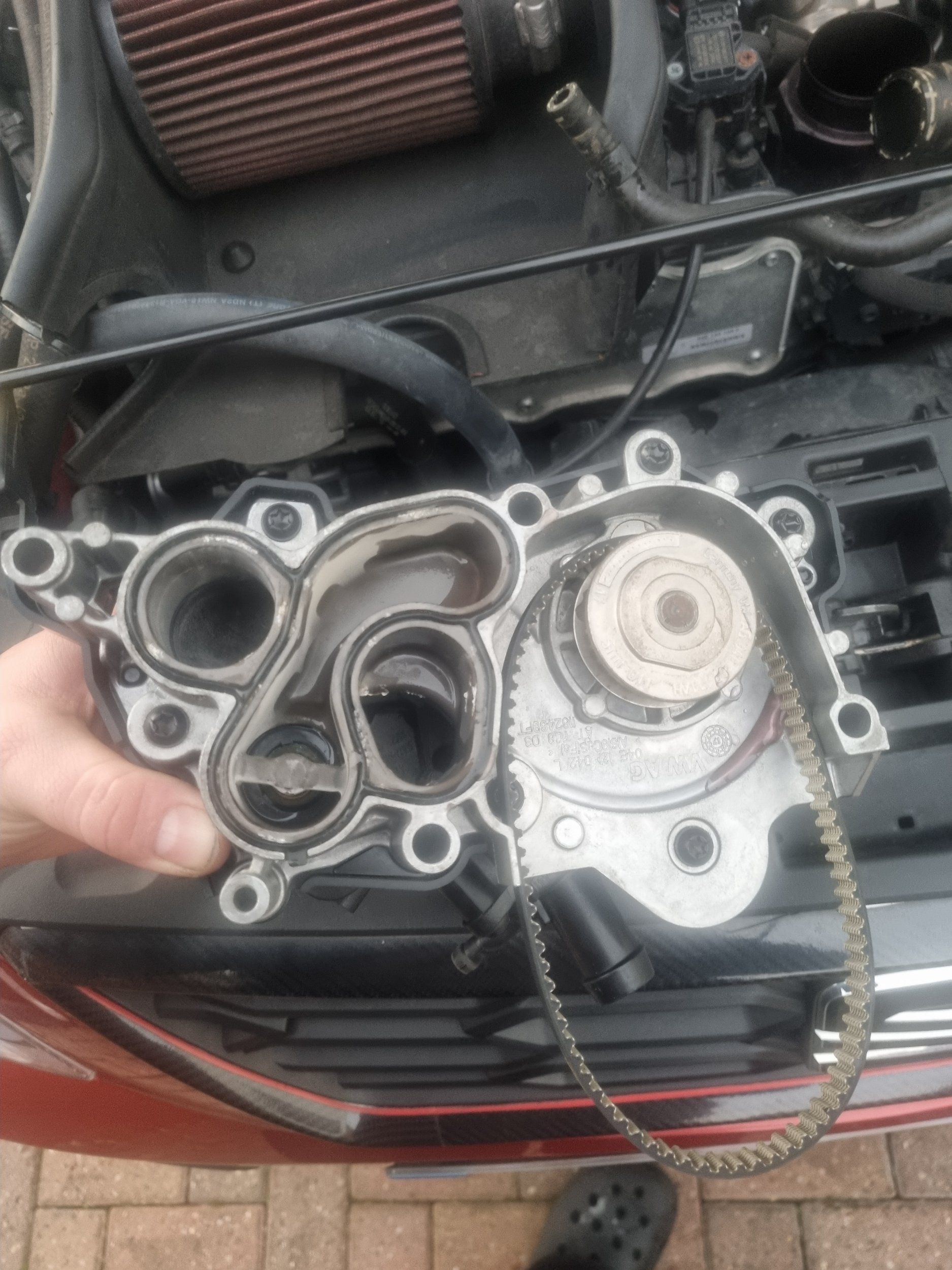

Pump and belt ready to be fitted:

Once done, you need to tension the drive belt. On the pump unit there is a hex shaped hole on the left that the size 10 allen/hex bit will fit. You need to insert the bit with the torque wrench attached and tighten it till the wrench clicks. Once it clicks, keep the pressue on the wrench and tighen up the bolts you put in with the torx bit and driver. Finally insert the lower bolt and torque it.

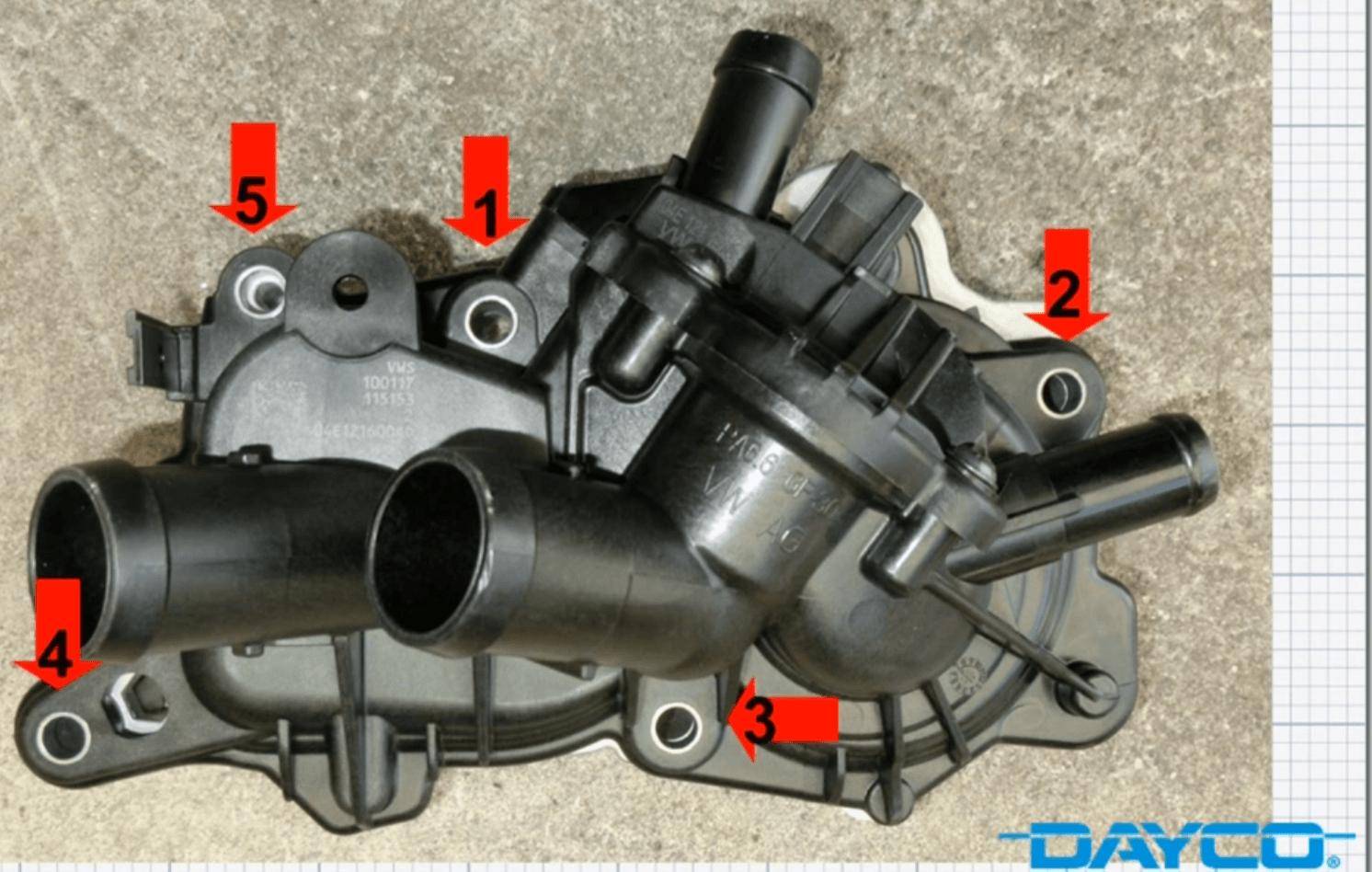

These bolts need to be tighten in a specific order, as shown in the following picture (Taken from the Dayco video linked here:

). Start at bolt 1 and end at bolt 5:

The torque figure is 30Nm for tensioning the belt, 12Nm for the housing bolts.

Hole for the allen/hex bit to fit:

Unit fitted, torque wrench in place:

Once the pump has been fully fitted, inspect the belt and make sure it is fitted correctly to both gears and has been tensioned. You then need to go back in reverse and refit everything in the order you removed it. Try not to lose too much coolant out of the pipes while reattactching them. It is recommended to replace the O-ring in the coupling for the coolant pipe and the radiator. I do not have a part number for this item at this time unfortunately.

Bleeding the system

The last thing to do is to refill the system and bleed air out of it. First re-attach the hose to the radiator if you haven't already. Next, either get fresh coolant, or if you are reusing the old coolant, start to refil the expansion tank. I used a funnel to try and avoid spilling it everywhere:

You will notice not all of the coolant will go back into the system. This is because there are now airlocks in the pipes and radiator. Start by squeezing the big pipes that attach to the pump unit to displace some of the air. This should allow you to pour in more coolant. When the coolant level doesn't go down anymore, make sure the car is safe and start the engine.

Caution: Be careful of moving parts and heat when working on a running engine

With the engine running, keep squeezing the bigger pipes to displace air within the system. Run the fans on max in the car and put the heating to max. As the engine runs the coolant will warm up and the pipes will become hotter. Keep squeezing the pipes around the pump unit. As you do this the coolant level should keep dropping, as it does keep topping it up. Eventually it won't drop anymore. This took me around 20 minutes. At this point, put the expansion tank cap back on and take the car for a 10 - 15 minute drive. Take some coolant with you as the level should drop as you drive and you may get a warning about this on the dash.

The air is tricky to get out and it took me 2 drives to fully displace all the air. If you have access to the correct vaccuum system to bleed coolant systems then I recommend you use this. However it is possible to do without it.

Once the air is bled the coolant level should no longer drop. Check the new unit for leaks over the coming days.

If all is well you are now done! Don't forget to refit the undertray if your car had one.

If the coolant level keeps dropping as you drive it, then you still have a leak somewhere and need to find it.

Any comments or questions please feel free to ask.

Thanks to RUM4MO for feedback and suggestions.

Many thanks,

Lozzy

Here is my guide for removing and refitting a new water pump/thermostat unit to the 1.4Tsi engine. My engine code is CZEA but this proceedure will be the same for other variants.

Tools required:

T25, T30 & T40 Torx bit & driver

Allen/Hex 10 bit & driver

Adjustable grips

Flat bladed screwdriver

Phillips screwdriver

Tub for collecting coolant

Torque wrench

Jack & axle stand, or access to a lift/ramp

Parts:

New unit (P/N 04E121600CR)

New drive belt (P/N 04E121605E)

Coolant (G12 Evo/ G13)

Getting started

Firstly comfirm the leak/failure is in fact the unit itself. The unit houses the thermostat and waterpump, both of which can fail seperately or can leak. In my case the unit was leaking coolant and I spotted some sitting on the top of the unit:

To start, you need to remove the undertray if one is present. I have covered this already in this guide here:

Servicing - Service guide - How to change the oil & filter - 1.4 MK3 Leon

Hi guys & gals, A nice simple guide today on how to change your oil & filter at service time. I'll also show how to change the pollen filter. I won't be talking about the air filter as I have a custom one on my car so there's nothing for me to...

Once that has been removed, you need to drain the coolant. The easiest way of doing this is from the bottom right side of the radiator. There is a connector secured with a metal clip. Pry out the clip with the flat bladed screwdriver and then pull the connector apart. Once you do this coolant will flow out of the radiator and the pipe. This is where the tub comes in to collect the coolant. As it is draining remove the cap from the expansion tank to aid removing the coolant. If you can, use something that will allow you to measure the amount of coolant that you remove. This is to ensure you put back the correct amount when refilling the system at the end of the job.

Connector with clip secured:

Clip unsecured:

Coolant flowing out:

With this done, you need to start dis-assembling parts around the unit at the top of the engine.

Start with removing the air filter pipes that run to the back of the engine. They are secured with clips, use the adjustable grips to loosen them. I have an intake kit on my engine so I can't show photo's of this however the area I've highlighted in this photo show where the pipes should be removed from:

With the intake pipes removed, you next need to remove the pipe that goes from the side of the engine to the turbo, then the plastic part attached to the turbo at the back. Both are secured with 2 Torx 30 screws. On the pipe there is a smaller pipe attached with a clip, remove this by squeezing the tabs together.

Pipe screws, smaller pipe to be removed highlighted by red arrow:

Screws for plastic part on turbo. The front one is in a tight position to get to so use of a skinny driver will be required. The rear one is located down the back. Red arrows show their location:

With these removed you should be left with this:

Next you need to move the wiring loom out of the way, and then start removing the 5 pipes attached to the unit. The wiring loom isn't very flexible but it is attached to the unit with 2 small clips on the right and a bigger clip on the left (as can be seen on the above picture). The bigger clip needs to be disconnected from the back with a screwdriver. Try and move the wiring onto the top of the engine to keep it out of the way.

Back of bigger clip, push the driver into the small hole (red arrow) and slide the clip off the bracket in the direction of the green arrow:

Now use the adjustable grips to remove the clips off the 5 pipes connected to the unit. There are 2 big pipes towards the front of the car, 2 medium sized towards the rear and a small one on top. As you remove these pipes, try to move them somewhere high to avoid un-necassery coolant loss. You will loose some coolant while moving these so put something on the floor to catch this. Keep the tub under the radiator while doing this as more coolant will flow out.

When you remove the clips the pipe will be stiff to pull off. Use the grips to lightly clamp around the end of the pipe and twist it till it moves easily. You will then be able to pull the pipe off with relative ease.

All pipes removed:

Next, remove the cover at the top of the engine next to the turbo. This covers the gear that drives the belt for the water pump. It is secured with 2 T30 screws (red arrows):

Removing the unit

The thermostat/pump unit is secured with 5 T30 screws. 2 are on top, 2 are at the ends and 1 is below. With these removed the pump may be stuck to the side of the engine so pull it lose and remove it. The drive belt will slip off the cam gear. The old gasket may stick and will leave residue stuck to the engine, remove this with a scouring pad until the metal is clean.

Pump removed, old gasket stuck to engine. Note in this picture you can see rust marks where the old unit has been leaking (next to the top of the gasket):

Old unit with drive belt and gasket (marks around top of the unit indicate where the leak was):

Area cleaned, ready for new unit to be fitted:

Fitting the new pump

With the area cleaned, it is time to fit the new pump unit. Before fitting, make sure the gasket is seated correctly in the grooves and apply a film of coolant to it. Put the new drive belt around the pump gear and slide it onto the drive gear as you put the unit into position on the engine. Ensure the belt position central to the drive gear. Once in position, put in the 2 bolts on top and the 2 bolts on the sides by hand, and tighten them by hand.

Pump and belt ready to be fitted:

Once done, you need to tension the drive belt. On the pump unit there is a hex shaped hole on the left that the size 10 allen/hex bit will fit. You need to insert the bit with the torque wrench attached and tighten it till the wrench clicks. Once it clicks, keep the pressue on the wrench and tighen up the bolts you put in with the torx bit and driver. Finally insert the lower bolt and torque it.

These bolts need to be tighten in a specific order, as shown in the following picture (Taken from the Dayco video linked here:

The torque figure is 30Nm for tensioning the belt, 12Nm for the housing bolts.

Hole for the allen/hex bit to fit:

Unit fitted, torque wrench in place:

Once the pump has been fully fitted, inspect the belt and make sure it is fitted correctly to both gears and has been tensioned. You then need to go back in reverse and refit everything in the order you removed it. Try not to lose too much coolant out of the pipes while reattactching them. It is recommended to replace the O-ring in the coupling for the coolant pipe and the radiator. I do not have a part number for this item at this time unfortunately.

Bleeding the system

The last thing to do is to refill the system and bleed air out of it. First re-attach the hose to the radiator if you haven't already. Next, either get fresh coolant, or if you are reusing the old coolant, start to refil the expansion tank. I used a funnel to try and avoid spilling it everywhere:

You will notice not all of the coolant will go back into the system. This is because there are now airlocks in the pipes and radiator. Start by squeezing the big pipes that attach to the pump unit to displace some of the air. This should allow you to pour in more coolant. When the coolant level doesn't go down anymore, make sure the car is safe and start the engine.

Caution: Be careful of moving parts and heat when working on a running engine

With the engine running, keep squeezing the bigger pipes to displace air within the system. Run the fans on max in the car and put the heating to max. As the engine runs the coolant will warm up and the pipes will become hotter. Keep squeezing the pipes around the pump unit. As you do this the coolant level should keep dropping, as it does keep topping it up. Eventually it won't drop anymore. This took me around 20 minutes. At this point, put the expansion tank cap back on and take the car for a 10 - 15 minute drive. Take some coolant with you as the level should drop as you drive and you may get a warning about this on the dash.

The air is tricky to get out and it took me 2 drives to fully displace all the air. If you have access to the correct vaccuum system to bleed coolant systems then I recommend you use this. However it is possible to do without it.

Once the air is bled the coolant level should no longer drop. Check the new unit for leaks over the coming days.

If all is well you are now done! Don't forget to refit the undertray if your car had one.

If the coolant level keeps dropping as you drive it, then you still have a leak somewhere and need to find it.

Any comments or questions please feel free to ask.

Thanks to RUM4MO for feedback and suggestions.

Many thanks,

Lozzy