Did my timing belt, coolant flush/change & thermostat before Christmas and though i'd share a couple pics a comments. Not meant to be a how-to as you can see that in the official maintenance manuals shared elsewhere.

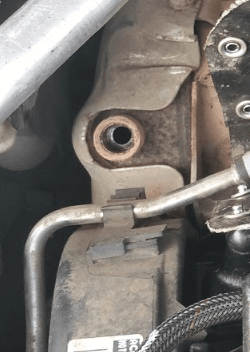

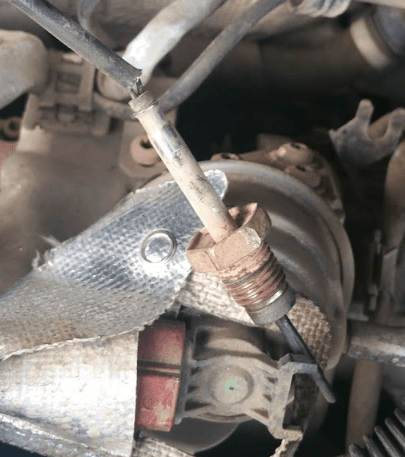

I spent the whole morning trying to work out how to undo the exhaust temp sensor. There is a special VAG tool which I don't have. It's 19mm hex, I tried a 19mm open spanner (can't use the ring end due to the cable which goes into the loom) but this thing is tight/corroded. I tried another 19mm hooked in the ring end of my 19mm which did fit but I could feel it flexing and stopped before rounding the nut of smashing my knuckles. In the end I sacrificed a 19mm deep socket by angle grinding a small slot in the end - this worked great with enough clearance for the wire to come out - lock a smaller lambda sensor socket. The nut was a little stuck to the sensor - should spin freely - so don't just keep unwinding the nut without holding the sensor still with some grips. I had to wiggle this back and forward to free the nut from the sensor.

Then front end on axle stands, and under tray, drivers side wheel and front wheel arch section removed for access.

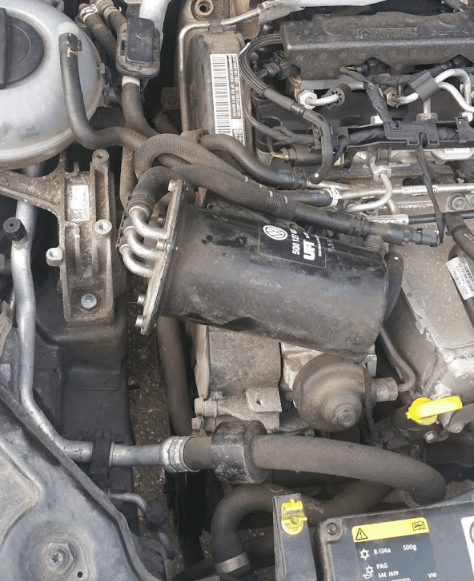

Undo fuel filter housing bolts which can then lift up and swing across.

Also remove header tank - I have a new (none silicate) tank to replace with.

Lots of coolant pipes to move out the way for access.

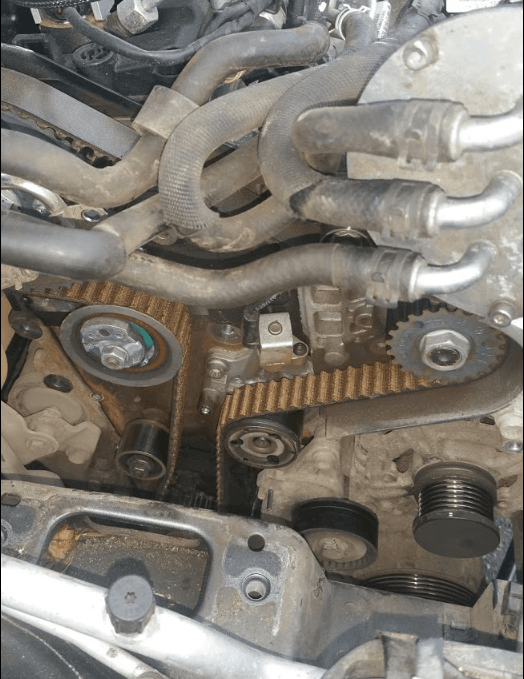

when you have access it's time to remove the top timing cover, simple enough to remove the small securing bolts but I found it tricky maneuvering it, persevered and got there in the end.

Need to support the engine on a jack - I used a large piece of wood to spread the load, and undo/remove the left hand engine mount and the bracket on the engine. the main mount is easy but the mount on the engine is fiddly and involves lots of up and down on the jack to gain access to the holes to remove the three large bolts.

These bolts are all triple squares - as are other 'important' bolts on VAG's so I would suggest getting a triple square set. I didn't have one, only have a couple of pieces, luckly I had one (M14 I brought to to my rear caliper bracket) which fit the large crank bolt used to rotate the engine (only clockwise). For the others I found my allen/hex set fit very well and worked 'ok' but I had to be very careful/precise would definitely get a triple square set if I did it again. Crank pulley also uses triple squares drives.

Time to lock the engine. You could get away with using drill bits or similar to lock the cam and pump (8mm I think) but the crank tool is unique so I had to but a locking set which included the pins anyway.

To lock the CAM you need to rotate the engine until you can get the pin between the clip and in the hole in the head - I missed it a few times! and if you do you just have to rotate the engine again!

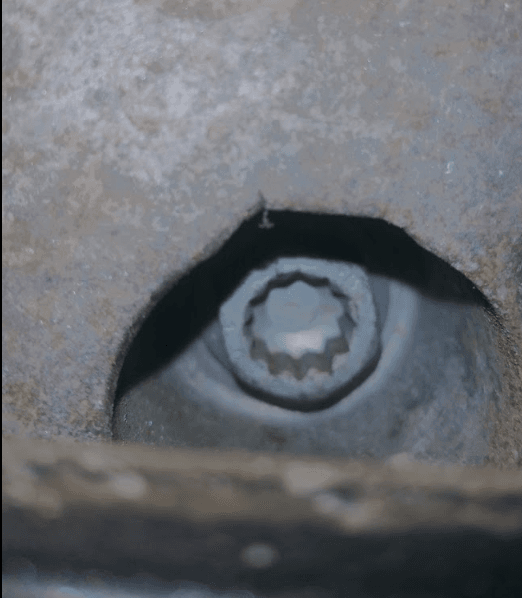

I used my phone/video camera to sneak up on the hole - quite fiddly as you can see.

You basically lock the engine crank/cam/pump - then remove the cam pim and using the counter hold tool crack the nut holding the cam pulley, then reinsert the pin, and then the same for the pump, remove the pin - counter hold tool - crack the nut - and reinsert the locking pin. You must not undo or do up the large nuts with the locking pins engaged, only use the counter hole tool.

With all the locking pins engaged you can undo the tensioner and remove the belt.

With the belt off drain the coolant system by removing hoses from the bottom of the radiator. then you can undo and pull out the pump. I still had a lot of coolant behind the pump so be ready with a rag to protect the crank pulley and bucket to collect coolant.

clean the mounting flange and hole for the pump and insert and torque up the new pump and bolts. This uses an o-ring to seal and should NOT use any sealant.

Mine is electro-mechanical, so the pump is turned like normal from the crank, but there is a shroud which moves back and forth over the impeller to aid in warm up times and efficiency. There are cases of these mechanisms getting stuck/stiff but there have been several OE number iterations and I wanted to keep it original so I brought the latest OE pump. Found it for a similar price to aftermarket copies on ebay.

then replace the idlers and tensioner - making sure the tensioner bracket locates on the hole in the block - this is hard to see so again I used my phone video cam to double check.

Fit the belt making sure the elongated holes in the cam and pump are centrally located.

Tension the tensioner, and 'nip' the cam and pump nuts.

Remove the timing tools and rotate the crank/engine a few times - re-check your locking tools all fit, and re-check your tensioner pointer is in the correct position.

Now you can torque up all nuts on the cam and pump using the counter hold tool. Turn the engine over and I also triple checked my tools all fit.

Now you can re-build in the reverse order, struggle with getting the engine mount bolts back in and the top co

I spent the whole morning trying to work out how to undo the exhaust temp sensor. There is a special VAG tool which I don't have. It's 19mm hex, I tried a 19mm open spanner (can't use the ring end due to the cable which goes into the loom) but this thing is tight/corroded. I tried another 19mm hooked in the ring end of my 19mm which did fit but I could feel it flexing and stopped before rounding the nut of smashing my knuckles. In the end I sacrificed a 19mm deep socket by angle grinding a small slot in the end - this worked great with enough clearance for the wire to come out - lock a smaller lambda sensor socket. The nut was a little stuck to the sensor - should spin freely - so don't just keep unwinding the nut without holding the sensor still with some grips. I had to wiggle this back and forward to free the nut from the sensor.

Then front end on axle stands, and under tray, drivers side wheel and front wheel arch section removed for access.

Undo fuel filter housing bolts which can then lift up and swing across.

Also remove header tank - I have a new (none silicate) tank to replace with.

Lots of coolant pipes to move out the way for access.

when you have access it's time to remove the top timing cover, simple enough to remove the small securing bolts but I found it tricky maneuvering it, persevered and got there in the end.

Need to support the engine on a jack - I used a large piece of wood to spread the load, and undo/remove the left hand engine mount and the bracket on the engine. the main mount is easy but the mount on the engine is fiddly and involves lots of up and down on the jack to gain access to the holes to remove the three large bolts.

These bolts are all triple squares - as are other 'important' bolts on VAG's so I would suggest getting a triple square set. I didn't have one, only have a couple of pieces, luckly I had one (M14 I brought to to my rear caliper bracket) which fit the large crank bolt used to rotate the engine (only clockwise). For the others I found my allen/hex set fit very well and worked 'ok' but I had to be very careful/precise would definitely get a triple square set if I did it again. Crank pulley also uses triple squares drives.

Time to lock the engine. You could get away with using drill bits or similar to lock the cam and pump (8mm I think) but the crank tool is unique so I had to but a locking set which included the pins anyway.

To lock the CAM you need to rotate the engine until you can get the pin between the clip and in the hole in the head - I missed it a few times! and if you do you just have to rotate the engine again!

I used my phone/video camera to sneak up on the hole - quite fiddly as you can see.

You basically lock the engine crank/cam/pump - then remove the cam pim and using the counter hold tool crack the nut holding the cam pulley, then reinsert the pin, and then the same for the pump, remove the pin - counter hold tool - crack the nut - and reinsert the locking pin. You must not undo or do up the large nuts with the locking pins engaged, only use the counter hole tool.

With all the locking pins engaged you can undo the tensioner and remove the belt.

With the belt off drain the coolant system by removing hoses from the bottom of the radiator. then you can undo and pull out the pump. I still had a lot of coolant behind the pump so be ready with a rag to protect the crank pulley and bucket to collect coolant.

clean the mounting flange and hole for the pump and insert and torque up the new pump and bolts. This uses an o-ring to seal and should NOT use any sealant.

Mine is electro-mechanical, so the pump is turned like normal from the crank, but there is a shroud which moves back and forth over the impeller to aid in warm up times and efficiency. There are cases of these mechanisms getting stuck/stiff but there have been several OE number iterations and I wanted to keep it original so I brought the latest OE pump. Found it for a similar price to aftermarket copies on ebay.

then replace the idlers and tensioner - making sure the tensioner bracket locates on the hole in the block - this is hard to see so again I used my phone video cam to double check.

Fit the belt making sure the elongated holes in the cam and pump are centrally located.

Tension the tensioner, and 'nip' the cam and pump nuts.

Remove the timing tools and rotate the crank/engine a few times - re-check your locking tools all fit, and re-check your tensioner pointer is in the correct position.

Now you can torque up all nuts on the cam and pump using the counter hold tool. Turn the engine over and I also triple checked my tools all fit.

Now you can re-build in the reverse order, struggle with getting the engine mount bolts back in and the top co

Last edited: