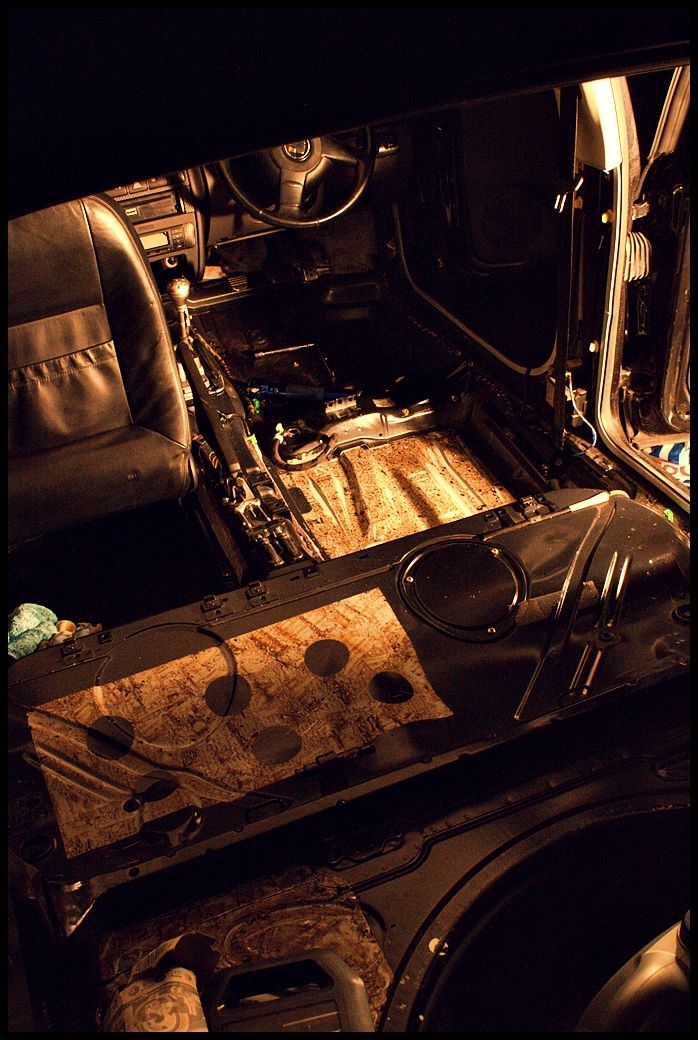

So got a few bits done on the car tonight

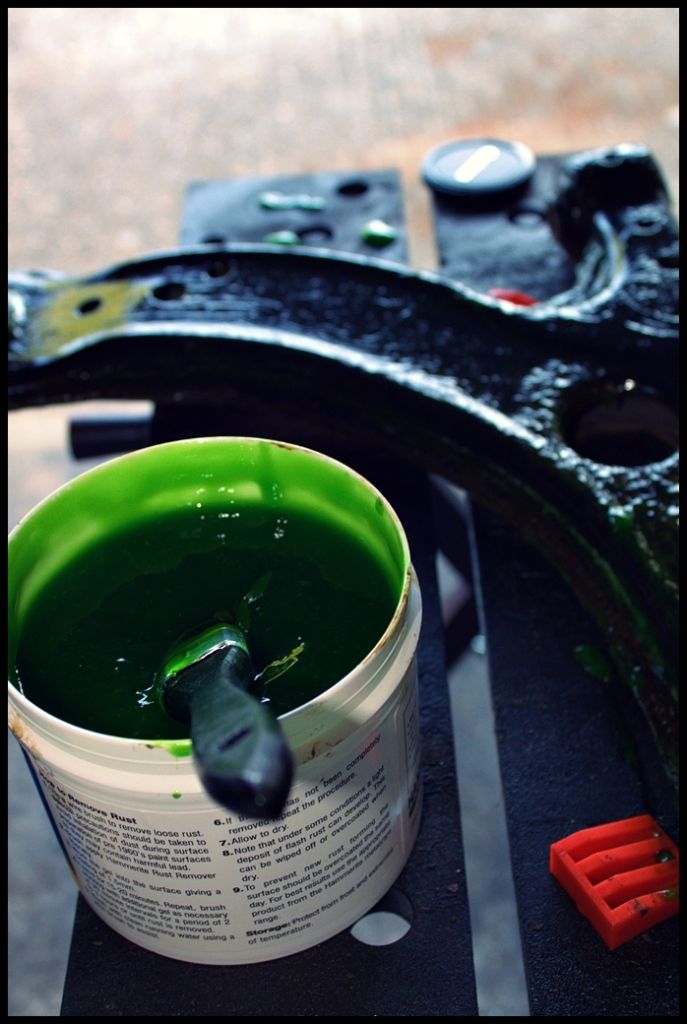

Phenolic gasket reinstalled. Now I didn't intend to put this back on, but I knew the far left stuf was missing. There is two studs on the left and right that hold the manifold on and the rest are bolts. So to do the job properly I had to remove the whole inlet manifold to get this stud in. What a fecking pain in the ass.

While it was off I couldn't reinstall the OEM gasket as it was foobarred and bent taking it off, so I thought I would reinstall the phenolic gasket again. WOW, what a ball ache. Because the gasket is so thick you literally have less than 1mm of thread left on the bolts to grip and screw in, which simply wasn't happening. For some reason I had a pack of bran new longer bolts. Where they came from I have no idea, but they were a god send

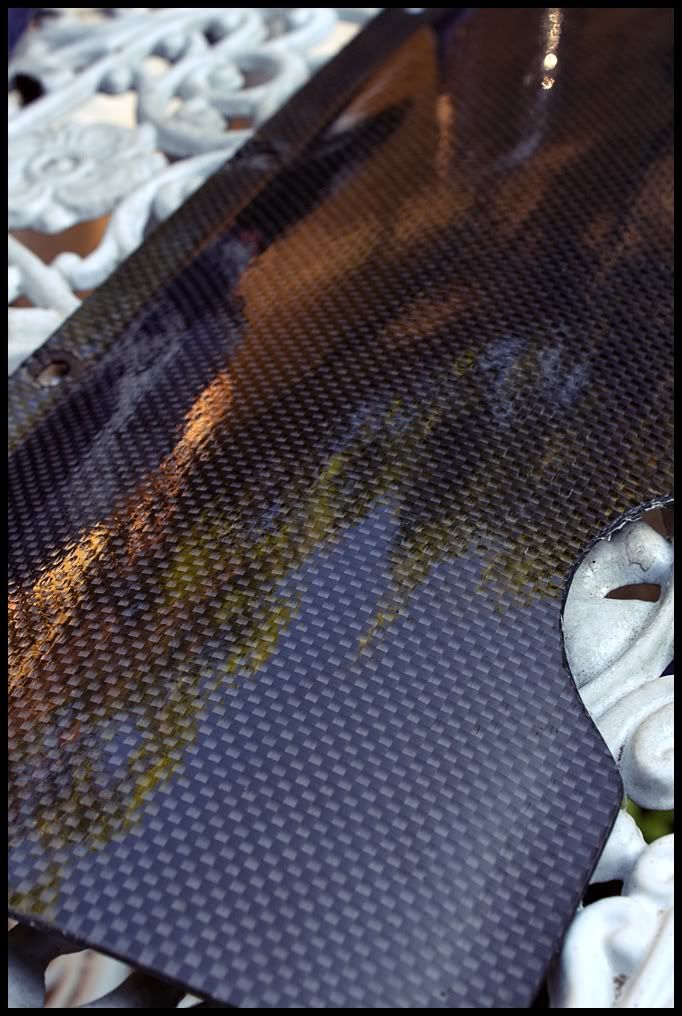

Gasket

Two types of OEM bolts. The longer bolt with 2mm more on the thread really is the difference with the bolts tightening and just turning

Part number for anyone interested

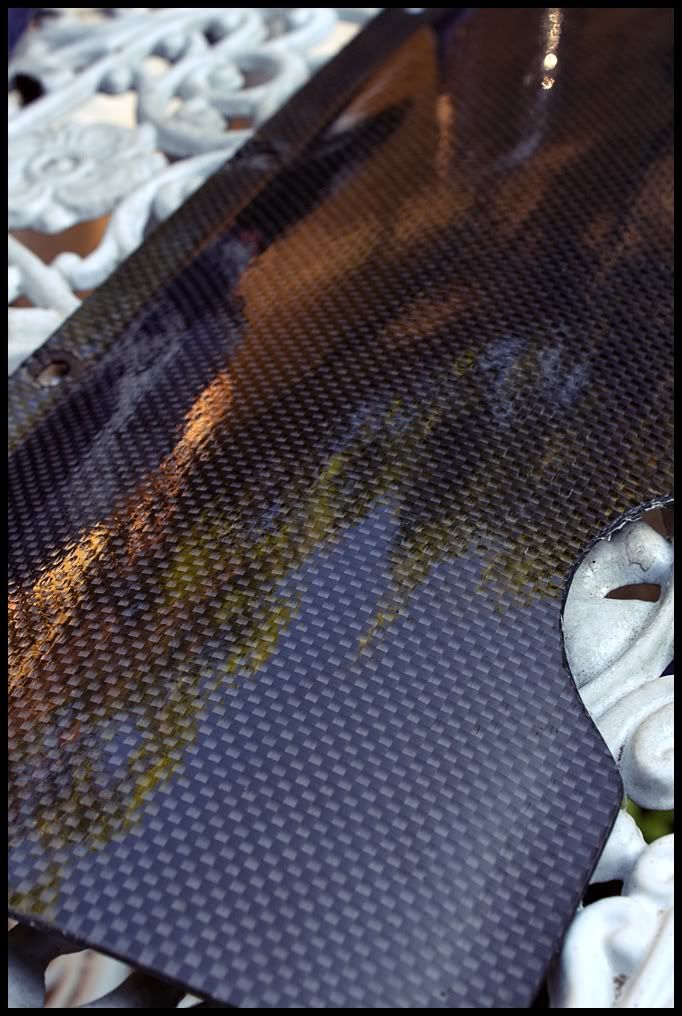

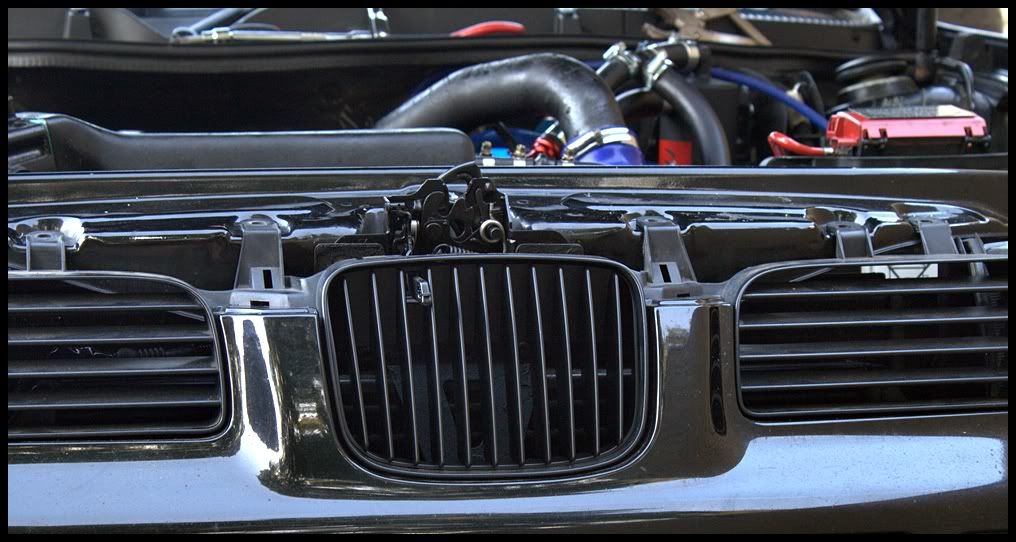

I then replaced the bonnet catch. For the first time in 6 months the bonnet now closes nicely

I then replaced the grill as the badget was fecked and snapped with a badgeless grill

I bought some braided hosing to replace the old hosing, as well as two hose couples too keep them tidy. Here is the cut and ready

I had some hose end tidiers, but on the old braided hoses they are much thinner and the new ones are much thicker, so these do not fit and I will have to order some new ones

I then got on with some more resistor crimping and tidying away the old cabling