Thats the plan mate.

I very much doubt you will see much gains if any atall on a k03.. who knows though! There not very expensive so its well worth a try, if not just remove them and sell them on.

May aswell give it a go then

Guest, 🎅🎄Looking for a stocking filler idea? Why not treat yourself or a loved one to our high quality CUPRA or SEAT valve caps. Order now from the merchandise store

Thats the plan mate.

I very much doubt you will see much gains if any atall on a k03.. who knows though! There not very expensive so its well worth a try, if not just remove them and sell them on.

I'm guessing it's not yours James?

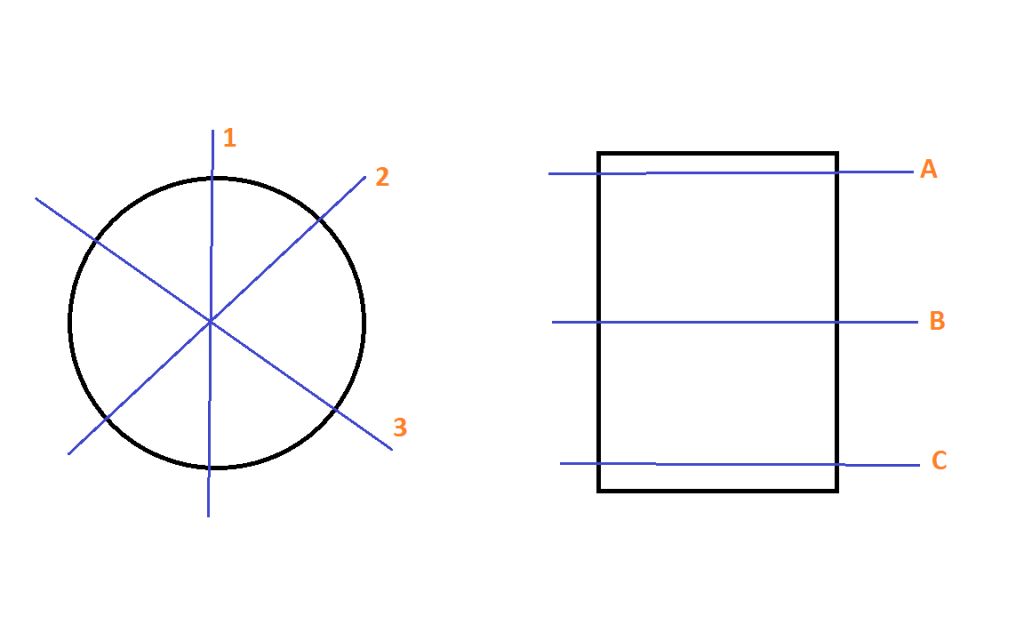

CYLINDER 1 CYLINDER 2 CYLINDER 3 CYLINDER 4

1 2 3 1 2 3 1 2 3 1 2 3

A 82.51 82.51 82.51 82.51 82.51 82.51 82.5 82.51 82.5 82.53 82.52 82.52

B 82.51 82.51 82.51 82.51 82.51 82.51 82.5 82.51 82.5 82.52 82.51 82.52

C 82.51 82.51 82.52 82.52 82.52 82.52 82.52 82.52 82.52 82.53 82.52 82.53

you are very exact in your work very impressed , time to get that badboy running me thinks

This is gonna help me I'm sure

Coming on wel james

Love ya wooden blocks dont ya lol

You measured this @ the dome or @ the skirt James?I then measured the pistons diameters and they were all 82.4mm on the dot.

You measured this @ the dome or @ the skirt James?

replied to your email as well.

Yeh the dome is normally slightly smaller mate , normally half way up the skirt at 90 degrees to the gudgeon / wrist pin.

edit - just seen your picture - exactly like you did it !!!!!!

Something is wrong then.At the skirt mate. The are supposedly 82.5mm pistons but I got both 82.4 on vernier calipers and a micrometer.

They were less at the dome so I took the largest diameter

Something is wrong then.

find out if they are a faulty batch from the piston manufacturer.

If they are listed as 82.5mm then they should be 82.5mm not 82.4mm

I know the machine shop will only bore to the specified piston but just make sure.

maybe search online for clearance specs for those specific pistons.

maybe search online for clearance specs for those specific pistons.