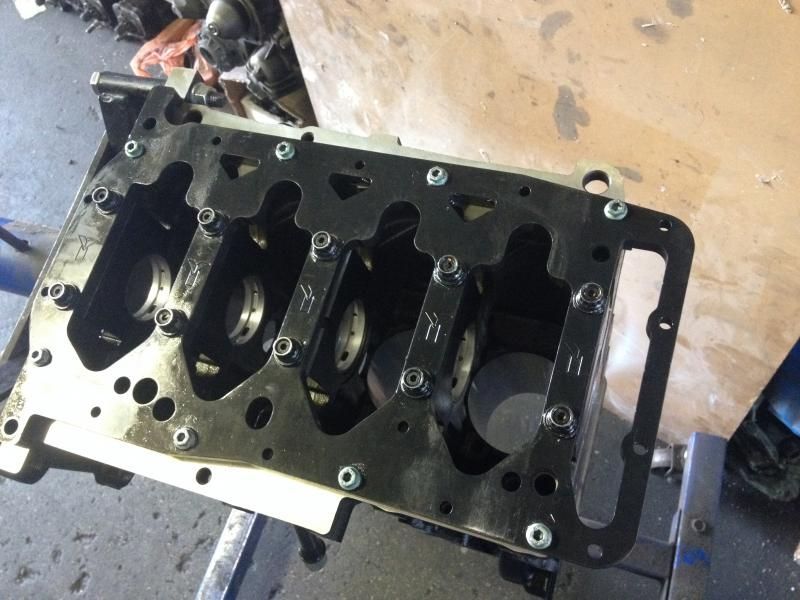

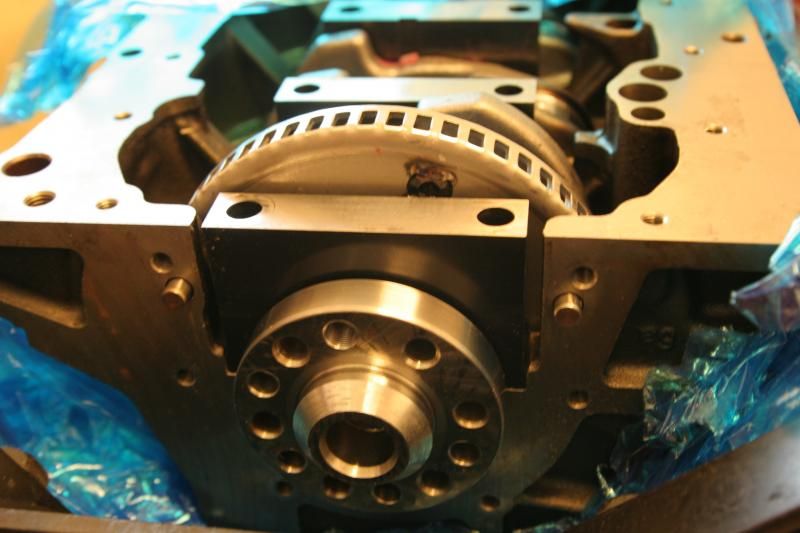

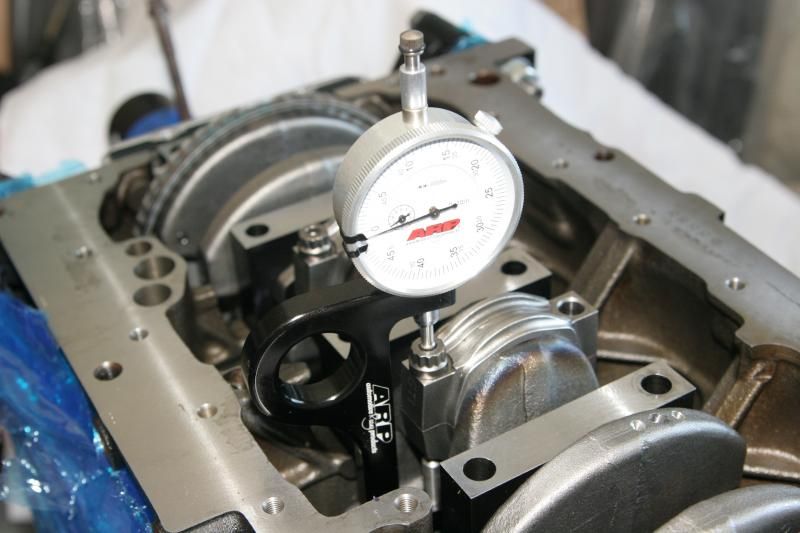

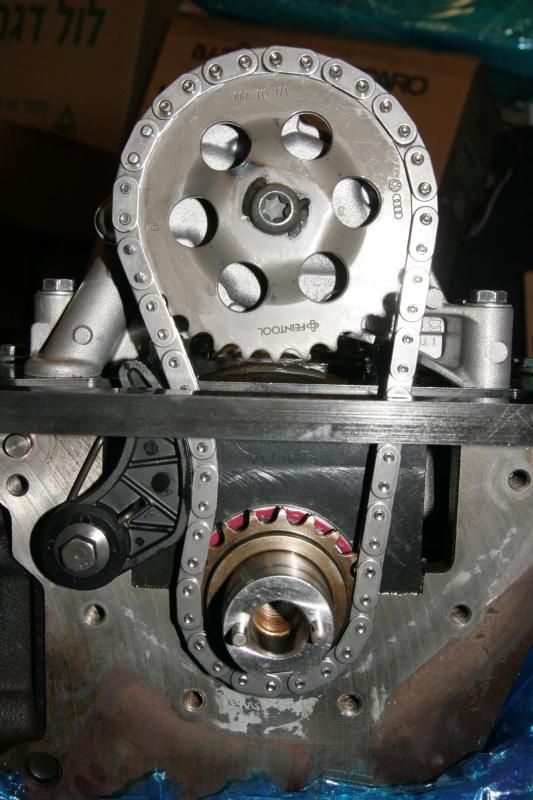

Got the engine block back from the workshop basically had the block bored an honed to 83mm both bottom and top decks surfaced and a line bore.it was a real pane according to the shop manager to install my billet mane caps even though I had CNC'd them from 4340 steel on an accurate CNC machine it seems they were not a perfect fit and had to have some work done to them to fit perfectly I guess on a production line I would have to rethink a few things over this is probably due to the engine block not being as symmetrical as we think and also I probably didn’t take into account the fact that the billet caps where less sustainable to stretching and compressing of the block on install, Also there was a complaint or two …. Something about the caps being very hard and the tools didn’t seem to be too happy with this.

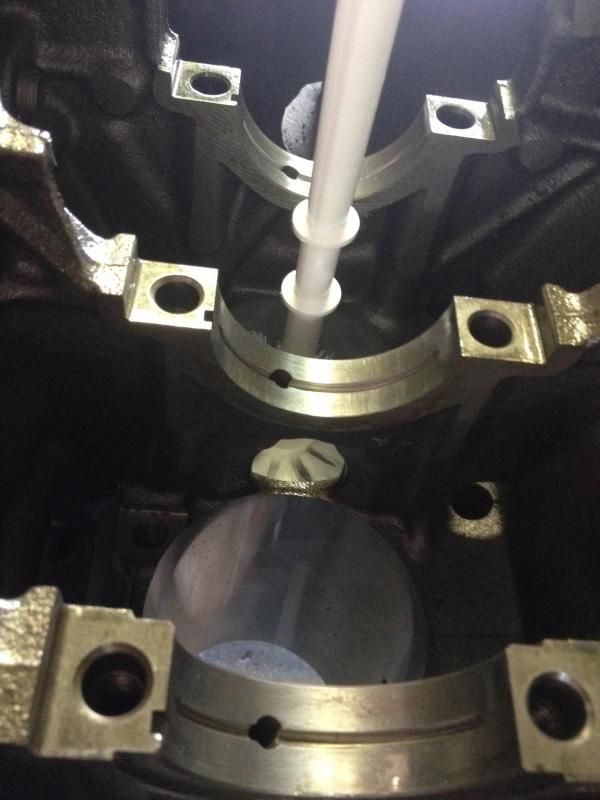

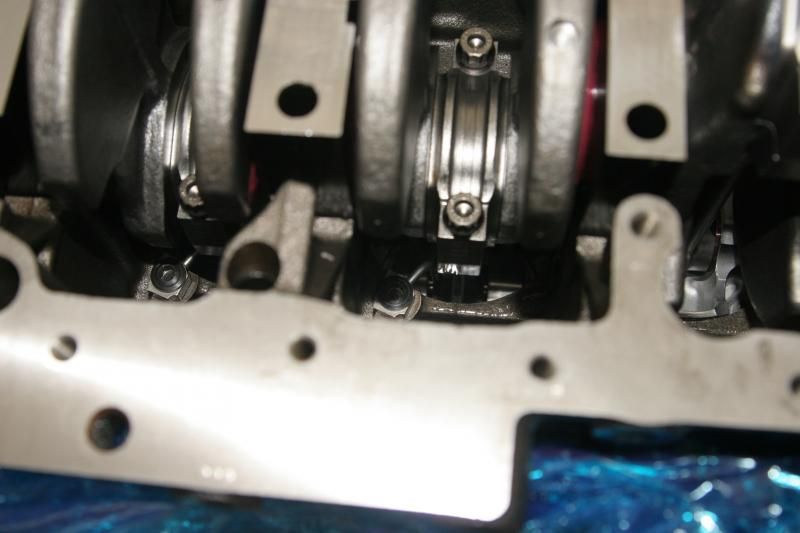

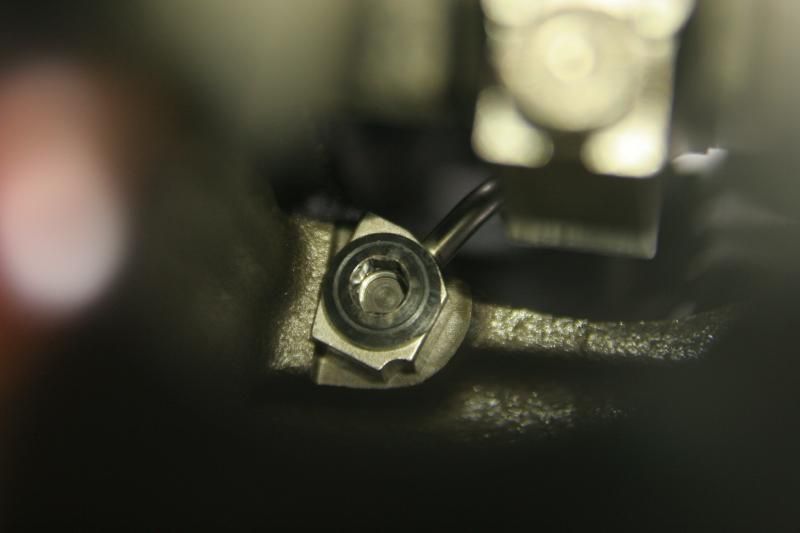

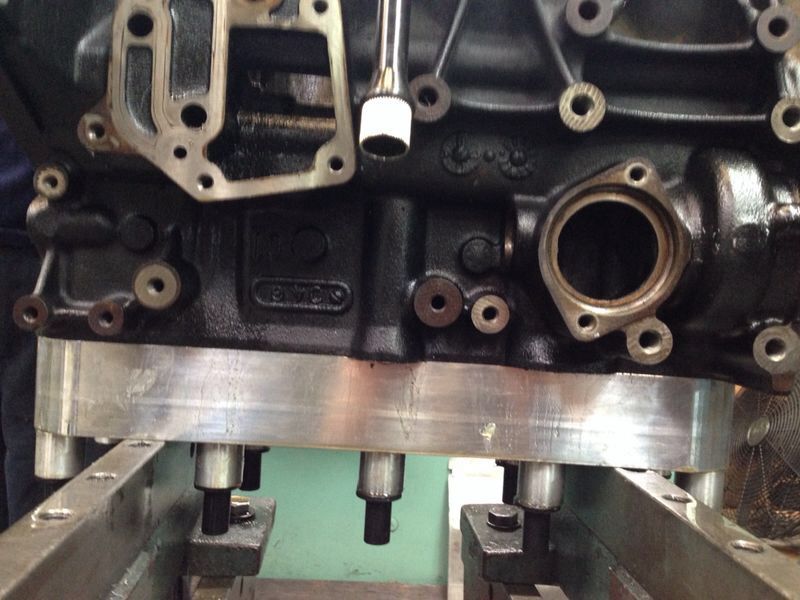

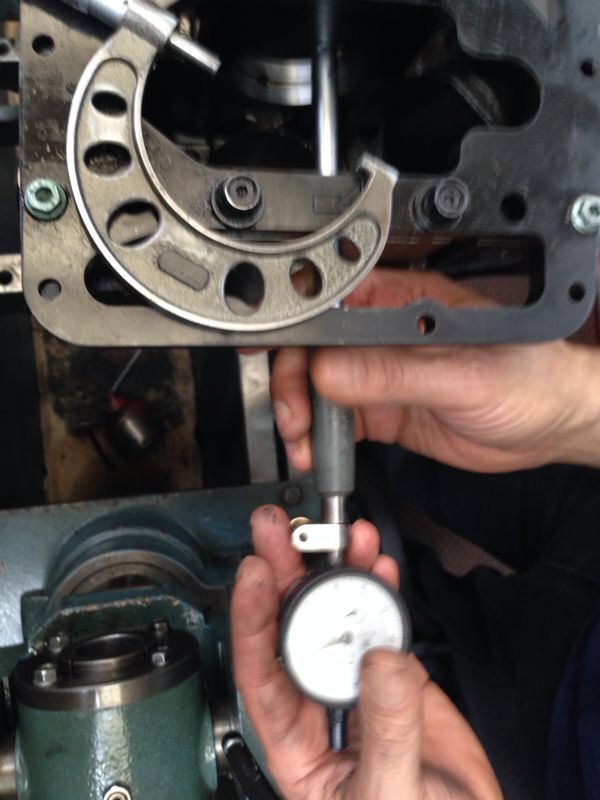

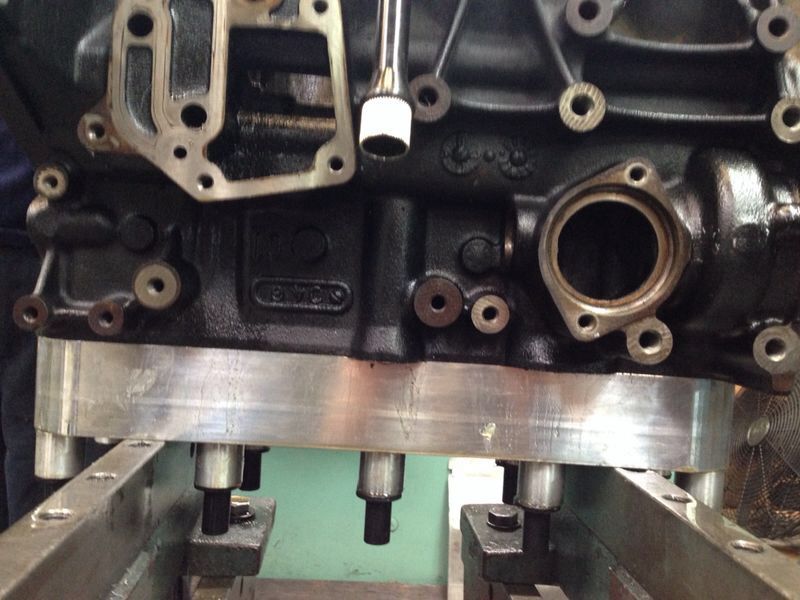

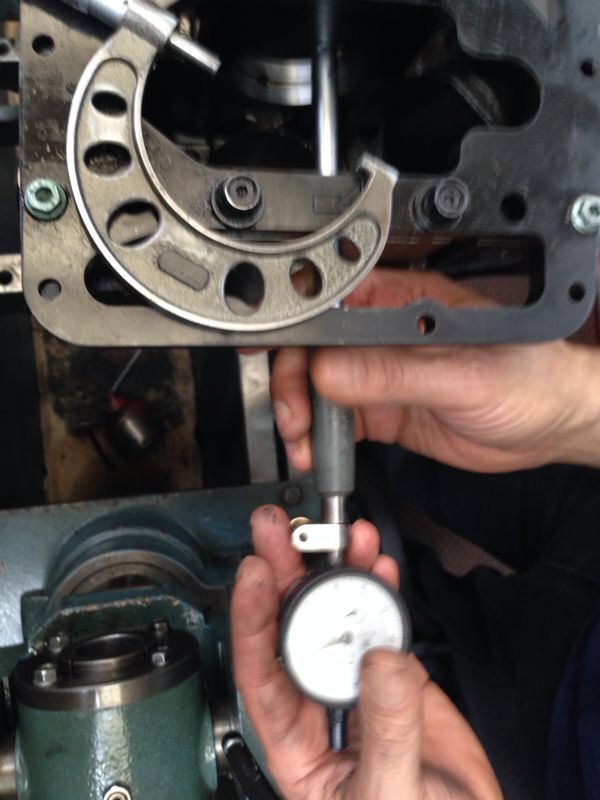

After fitting the main caps I had the bottom deck milled flat with the caps in order to accommodate the 4340 billet main girdle that i also make on a CNC and surfaced the top deck as well for a perfect head gasket seal. At the end of it all the block was bored out too 83mm and had a professional hone done to it as well. Needless to say that during the whole operation I had a torque plate mounted to the block with the head studs torqued to the correct ratings. You can also see the oil grove in the main bearing the I CNC'd into the block to help oiling the bearing at high RPM.

Sorry about the crapy pictures they were taken by the shop manager on some type of smart phone.

After fitting the main caps I had the bottom deck milled flat with the caps in order to accommodate the 4340 billet main girdle that i also make on a CNC and surfaced the top deck as well for a perfect head gasket seal. At the end of it all the block was bored out too 83mm and had a professional hone done to it as well. Needless to say that during the whole operation I had a torque plate mounted to the block with the head studs torqued to the correct ratings. You can also see the oil grove in the main bearing the I CNC'd into the block to help oiling the bearing at high RPM.

Sorry about the crapy pictures they were taken by the shop manager on some type of smart phone.

Last edited: